Magnesium-doped titanium dioxide based perovskite solar cell and preparation method thereof

A technology of solar cells and titanium dioxide, applied in circuits, photovoltaic power generation, electrical components, etc., can solve problems such as high density of states, lower process temperature, and low film conductivity, and achieve high stability, large surface area, and reduced grain boundaries Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

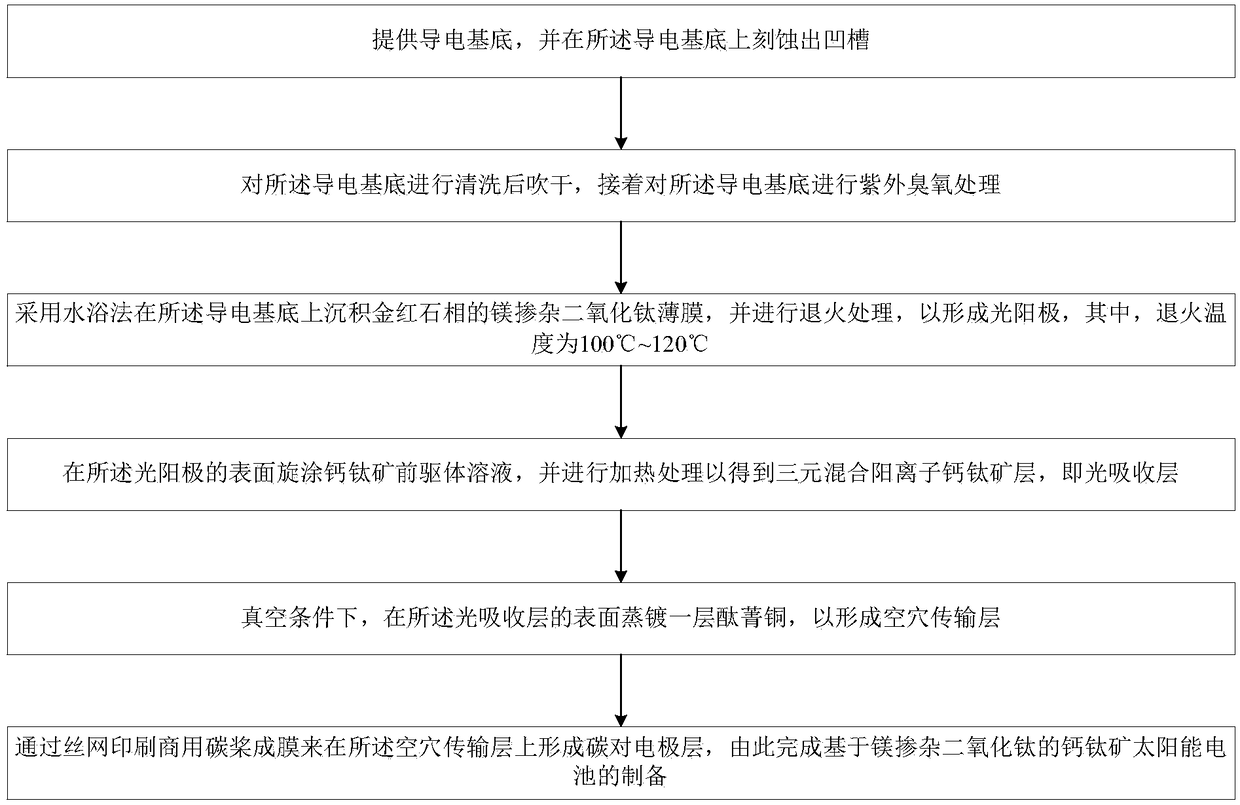

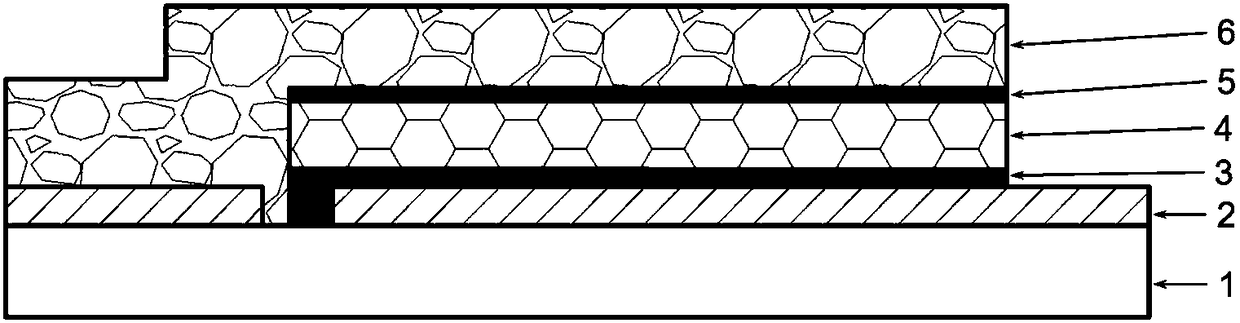

[0034] The preparation method of the perovskite solar cell based on nickel-doped titanium dioxide mainly includes the following steps:

[0035] Step 1, providing a conductive base, and etching grooves on the conductive base. Specifically, FTO conductive glass is provided as a conductive substrate, and the conductive substrate includes a substrate glass 1 and an FTO conductive layer 2 disposed on the substrate glass 1, the groove runs through the FTO conductive layer 2, and is adjacent to One end of the conductive substrate; the conductive substrate is treated with dilute hydrochloric acid and zinc powder with a concentration of 2mol / L-2.5mol / L to etch the groove. Among them, the FTO conductive glass is sputtered with a layer of fluorine-doped SnO on the silicon-boron-based substrate glass. 2 conductive layer of glass.

[0036] In step 2, the conductive substrate is cleaned and dried, and then the conductive substrate is treated with ultraviolet and ozone. Specifically, the ...

Embodiment 1

[0045] The preparation method of the magnesium-doped titanium dioxide-based perovskite solar cell provided by the first embodiment of the present invention mainly includes the following steps:

[0046] 11. Using FTO conductive glass as the conductive substrate, treat the FTO conductive layer of the conductive substrate with dilute hydrochloric acid and zinc powder at a concentration of 2 mol / L to etch grooves.

[0047] 12. Use acetone, ethanol, and deionized water to ultrasonically clean the conductive substrate for 15 minutes, then dry it with nitrogen flow, and then treat the FTO conductive layer with ultraviolet and ozone for 30 minutes.

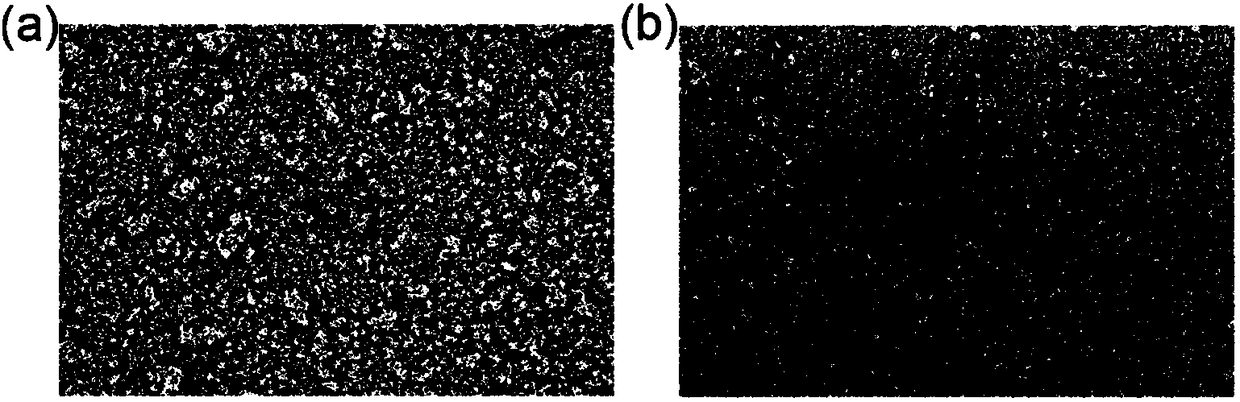

[0048] 13. Place the conductive substrate vertically in the beaker containing the growth solution after being fixed by the cage, then place the beaker in a constant temperature water bath, and control the reaction temperature at 70°C, and the growth time is 3 hours, and finally Anneal for 1-1.5 hours to form a photoanode, and the annealin...

Embodiment 2

[0053] The preparation method of the magnesium-doped titanium dioxide-based perovskite solar cell provided by the second embodiment of the present invention mainly includes the following steps:

[0054] 21. Using FTO conductive glass as the conductive substrate, treat the FTO conductive layer of the conductive substrate with dilute hydrochloric acid and zinc powder at a concentration of 2 mol / L to etch grooves.

[0055] 22. Use acetone, ethanol, and deionized water to ultrasonically clean the conductive substrate for 15 minutes, then dry it with nitrogen flow, and then treat the FTO conductive layer with ultraviolet and ozone for 30 minutes.

[0056] 23. Place the conductive substrate vertically in the beaker containing the growth solution after being fixed by the cage, then place the beaker in a constant temperature water bath, and control the reaction temperature at 70°C, and the growth time is 3 hours, and finally Anneal for 1-1.5 hours to form a photoanode, and the anneali...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Thickness | aaaaa | aaaaa |

| Thickness | aaaaa | aaaaa |

| Thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com