Preparation method of lithium titanate negative electrode current collector

A current collector, lithium titanate technology, used in electrode manufacturing, battery electrodes, electrical components, etc., to achieve the effects of improving wettability, short drying time, and good compatibility

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

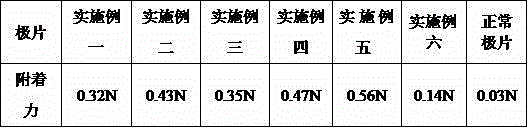

Examples

preparation example Construction

[0019] The preparation method of the lithium titanate negative electrode current collector is to select etched copper foil as the negative electrode current collector, soak the negative electrode current collector in the modified solution and perform ultrasonic treatment on the surface, the ultrasonic time is 5~30min, the temperature is 20-40℃, ultrasonic The frequency is 10-30KHz;

[0020] After ultrasonic treatment and drying, after drying, the negative electrode collector is coated with lithium titanate negative electrode slurry, and the density of the coated double sides is 180-220g / m 2 .

[0021] The solvent of the modified solution is N-methylpyrrolidone or acetone, and the additive is one of titanate coupling agent, aluminate coupling agent, borate coupling agent, aluminum-titanium composite coupling agent or Various, the mass percentage of the additive in the modified solution is: 0.3%-7%. The components and mass proportions in the lithium titanate slurry are: conduc...

Embodiment 1

[0023] In this example, the mass ratio of each substance in the lithium titanate slurry is lithium titanate: binder (PVDF-5130): conductive agent (KS-6) = 92.5:5:2.5; solvent is N-methylpyrrolidone ( NMP), the solid content is 67.5%. All substances are fully mixed and uniformly stirred in a solvent to form a paste, and the lithium titanate negative electrode slurry is prepared.

[0024] Soak the etched copper foil in an NMP solution with a mass fraction of 0.5% titanate coupling agent for ultrasonic treatment at a temperature of 30°C for 10 minutes and an ultrasonic frequency of 15KHz.

Embodiment 2

[0026] In this example, the mass ratio of each substance in the lithium titanate slurry is lithium titanate: binder (PVDF-5130): conductive agent (KS-6) = 92.5:5:2.5; the solvent is NMP, and the solid content is 67.5%. All substances are fully mixed and uniformly stirred in a solvent to form a paste, and the lithium titanate negative electrode slurry is prepared.

[0027] Soak the etched copper foil in an NMP modification solution with a mass fraction of 1.7% aluminate coupling agent for ultrasonic treatment at a temperature of 30°C for 15 minutes and an ultrasonic frequency of 15KHz.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com