Method of preparing silicon carbide MOSFET gate dielectric layer

A gate dielectric layer, silicon carbide technology, applied in electrical components, circuits, semiconductor devices, etc., can solve the problems of C cluster aggregation, high thermal budget of SiO2 gate dielectric layer, low dielectric constant, etc., to reduce the electric field strength, simplify the Device fabrication process, effect of high dielectric constant

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

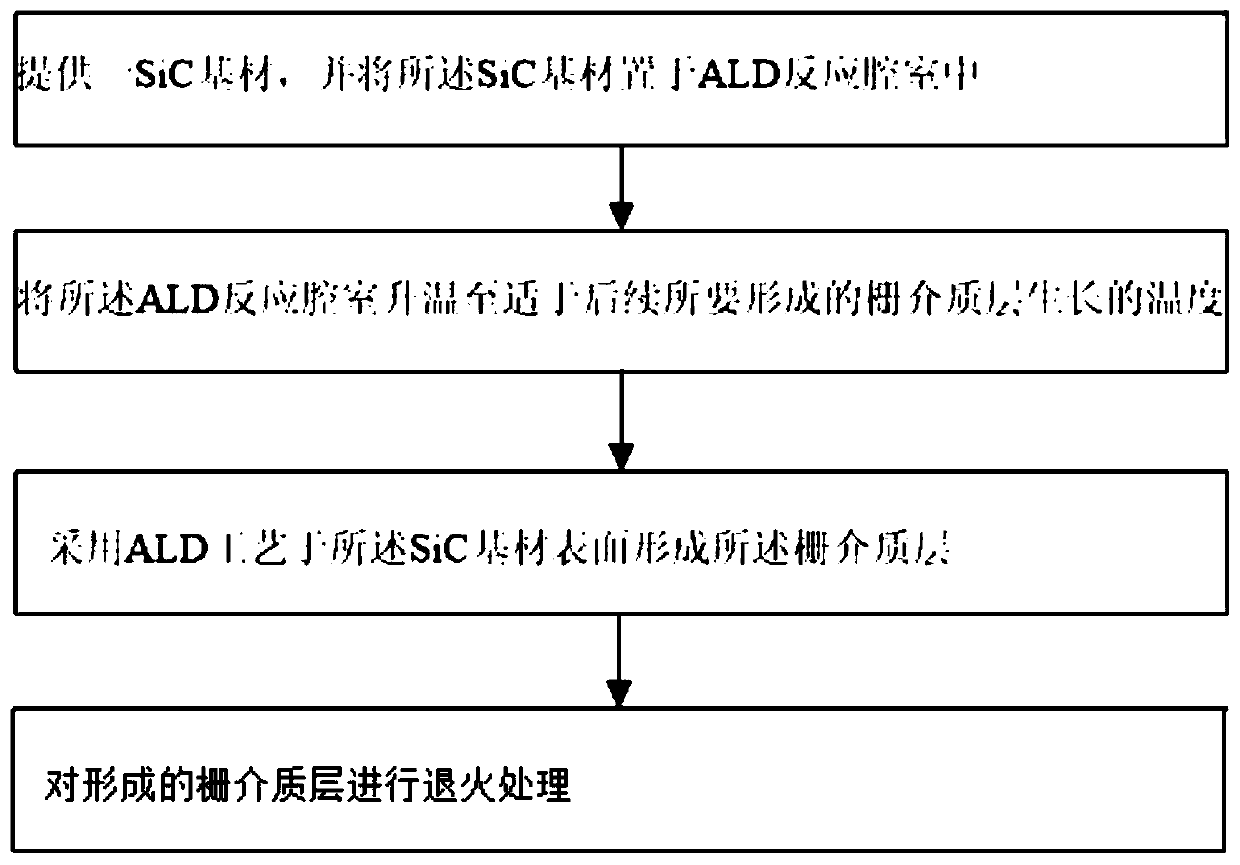

[0052] Such as figure 1 As shown, the present invention provides a method for preparing a silicon carbide MOSFET gate dielectric layer, comprising the following steps:

[0053] S1: Provide the SiC substrate and place the SiC substrate in the ALD reaction chamber;

[0054] S2: heating the ALD reaction chamber;

[0055] S3: Using the ALD process to sequentially grow SiO on the surface of the SiC substrate 2 thin film and Al 2 o 3 thin film to form a gate dielectric layer.

[0056] S4: performing annealing treatment on the formed gate dielectric layer in an oxygen atmosphere.

[0057] A method for preparing a silicon carbide MOSFET gate dielectric layer according to the present invention will be described in detail below with reference to the accompanying drawings.

[0058] Such as figure 1 As shown in S1, perform step S1, provide a SiC substrate, and place the SiC substrate in the ALD reaction chamber;

[0059] Specifically, the SiC substrate includes but is not limited ...

Embodiment 2

[0107] Such as figure 1 As shown, the present invention provides a method for preparing a silicon carbide MOSFET gate dielectric layer, comprising the following steps:

[0108] S1: Provide the SiC substrate and place the SiC substrate in the ALD reaction chamber;

[0109] S2: heating the ALD reaction chamber;

[0110] S3: Using the ALD process to sequentially grow SiO on the surface of the SiC substrate 2 thin film and Al 2 o 3 thin film to form a gate dielectric layer.

[0111] S4: performing annealing treatment on the formed gate dielectric layer in an oxygen atmosphere.

[0112] A method for preparing a silicon carbide MOSFET gate dielectric layer according to the present invention will be described in detail below with reference to the accompanying drawings.

[0113] Such as figure 1 As shown in S1, perform step S1, provide a SiC substrate, and place the SiC substrate in the ALD reaction chamber;

[0114] Specifically, the SiC substrate includes but is not limited ...

Embodiment 3

[0162] Such as figure 1 As shown, the present invention provides a method for preparing a silicon carbide MOSFET gate dielectric layer, comprising the following steps:

[0163] S1: Provide the SiC substrate and place the SiC substrate in the ALD reaction chamber;

[0164] S2: heating the ALD reaction chamber;

[0165]S3: Using the ALD process to sequentially grow SiO on the surface of the SiC substrate 2 thin film and Al 2 o 3 thin film to form a gate dielectric layer.

[0166] S4: performing annealing treatment on the formed gate dielectric layer in an oxygen atmosphere.

[0167] A method for preparing a silicon carbide MOSFET gate dielectric layer according to the present invention will be described in detail below with reference to the accompanying drawings.

[0168] Such as figure 1 As shown in S1, perform step S1, provide a SiC substrate, and place the SiC substrate in the ALD reaction chamber;

[0169] Specifically, the SiC substrate includes but is not limited t...

PUM

| Property | Measurement | Unit |

|---|---|---|

| strength | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

| strength | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com