Low-loss, high-temperature and lead-free capacitor material and preparation method thereof

A technology of capacitors and capacitor ceramics, applied in the field of dielectrics, can solve problems such as insufficient environmental protection and large lead pollution, and achieve lower dielectric loss, high dielectric constant, and improved interface carrier transport and dipole polarization state. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

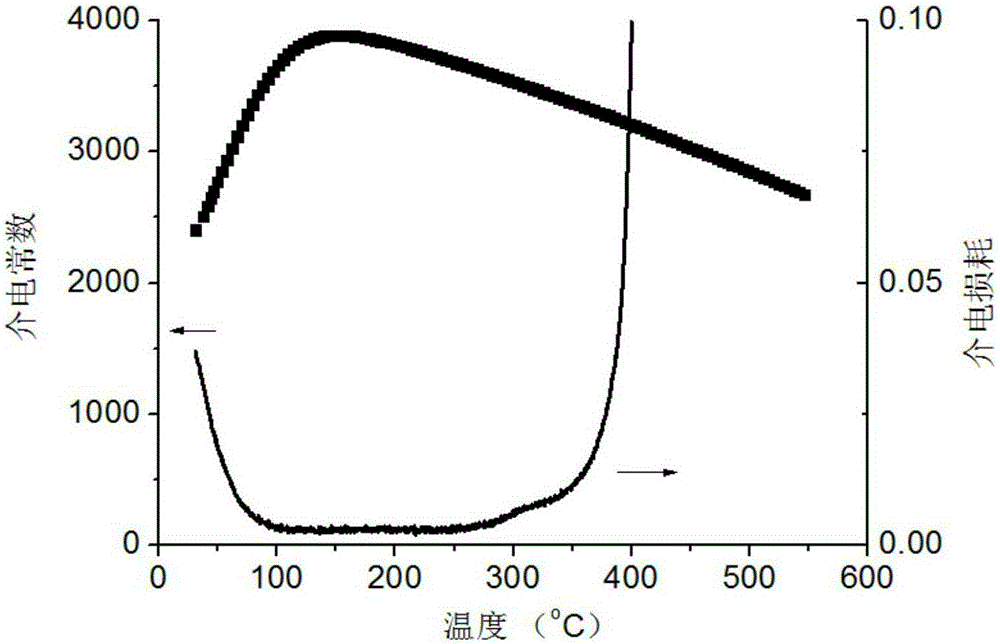

Embodiment 1

[0023] (1) Using analytically pure cerium oxide, barium carbonate, strontium carbonate, titanium dioxide, bismuth nitrate, tetrabutyl titanate and magnesium nitrate as raw materials, the compound (Ba 0.8 Sr 0.2 ) 0.85 Ce 0.1 TiO 3 Powder;

[0024] (2) Analytical pure magnesium nitrate and bismuth nitrate are weighed and prepared in a molar ratio of 1:2, dissolved in ethylene glycol monomethyl ether, and the mass of ethylene glycol monomethyl ether is 5 times that of magnesium nitrate and bismuth nitrate. Obtain a homogeneous solution;

[0025] (3) Based on the magnesium nitrate in step (2), measure the corresponding amount of tetrabutyl titanate with a graduated cylinder according to the Mg:Ti molar ratio of 1:1 and dissolve it in methanol. The volume of methanol is the volume of tetrabutyl titanate 10 times of that, fully stirred, so that tetrabutyl titanate was evenly dissolved in methanol to obtain a homogeneous solution;

[0026] (4) Drop the solution obtained in ste...

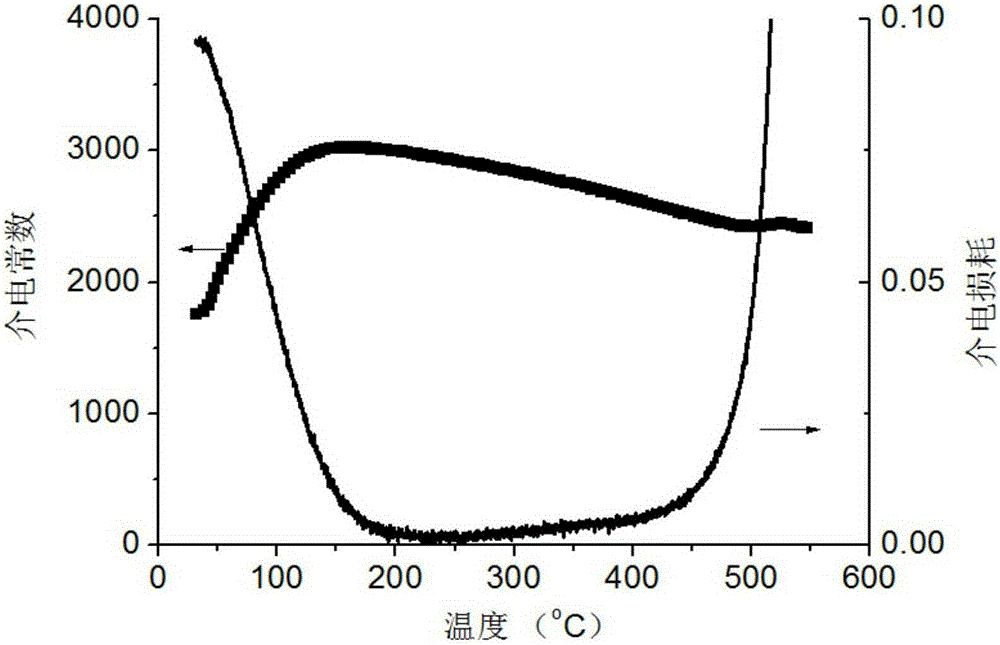

Embodiment 2

[0033] (1) Using analytically pure cerium oxide, barium carbonate, strontium carbonate, titanium dioxide, bismuth nitrate, tetrabutyl titanate and magnesium nitrate as raw materials, the compound (Ba 0.8 Sr 0.2 ) 0.85 Ce 0.1 TiO 3 ;

[0034] (2) Analytical pure magnesium nitrate and bismuth nitrate are weighed and prepared according to a molar ratio of 1:2, dissolved in ethylene glycol monomethyl ether, and the mass of ethylene glycol monomethyl ether is 7 times that of the raw material to obtain a homogeneous solution ;

[0035] (3) Based on the magnesium nitrate in step (2), measure the corresponding amount of tetrabutyl titanate with a graduated cylinder according to the Mg:Ti molar ratio of 1:1 and dissolve it in methanol. The volume of methanol is the volume of tetrabutyl titanate 8 times of that, fully stirred, so that tetrabutyl titanate was evenly dissolved in methanol to obtain a homogeneous solution;

[0036] (4) Drop the solution obtained in step (3) into the ...

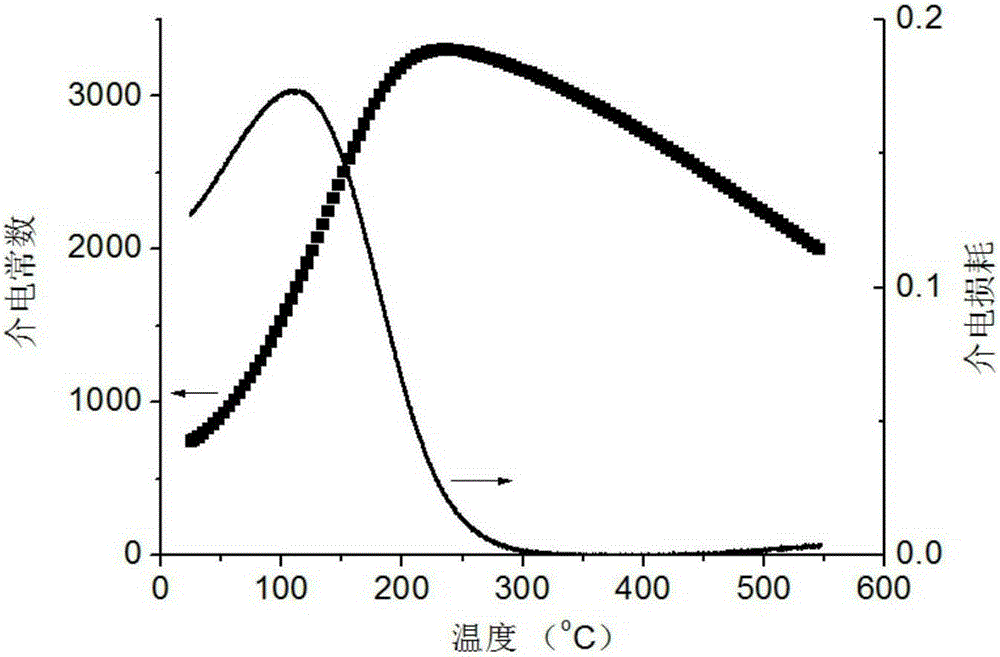

Embodiment 3

[0043] (1) Using analytically pure cerium oxide, barium carbonate, strontium carbonate, titanium dioxide, bismuth nitrate, tetrabutyl titanate and magnesium nitrate as raw materials, the compound (Ba 0.8 Sr 0.2 ) 0.7 Ce 0.2 TiO 3 ;

[0044] (2) Use analytical grade magnesium nitrate and bismuth nitrate to weigh the ingredients in a molar ratio of 1:2, dissolve them in ethylene glycol monomethyl ether, and the quality of ethylene glycol monomethyl ether is 8 times that of the raw material. to obtain a homogeneous solution;

[0045] (3) Based on the magnesium nitrate in step (2), measure the corresponding amount of tetrabutyl titanate with a graduated cylinder according to the Mg:Ti molar ratio of 1:1 and dissolve it in methanol. The volume of methanol is the volume of tetrabutyl titanate 7 times of that, fully stirred, so that tetrabutyl titanate was evenly dissolved in methanol to obtain a homogeneous solution;

[0046] (4) Drop the solution obtained in step (2) into the...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com