Rigid-flexible combined printed circuit board preparation method

A rigid-flexible combination and circuit board technology, which is applied in the direction of multilayer circuit manufacturing and can solve problems affecting bending performance and other issues

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0030] The present invention will be further elaborated below in conjunction with the accompanying drawings and embodiments.

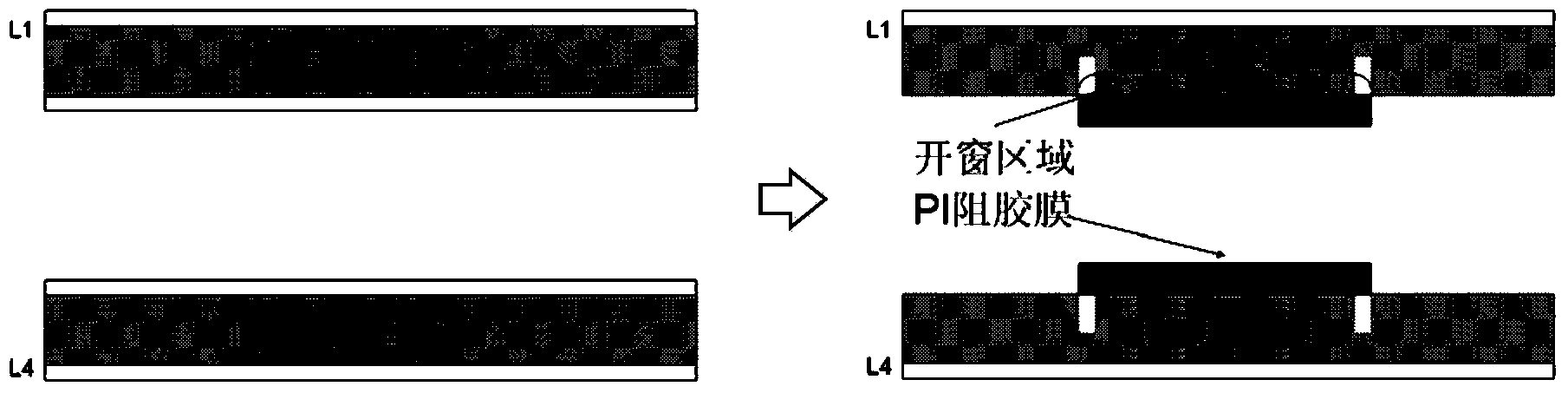

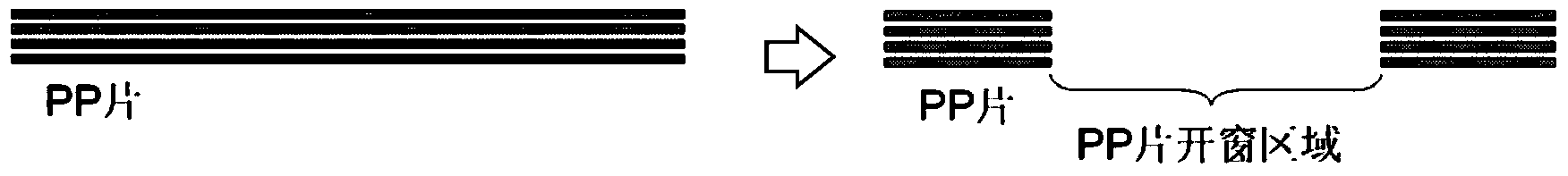

[0031] In this embodiment, a 4-layer rigid-flex circuit board is prepared, wherein the second and third layers are flexible layers, and the first and fourth layers are rigid layers. There is also a dielectric layer (flowable prepreg) between the 1st and 2nd layers and the 3rd and 4th layers. The specific production steps are as follows:

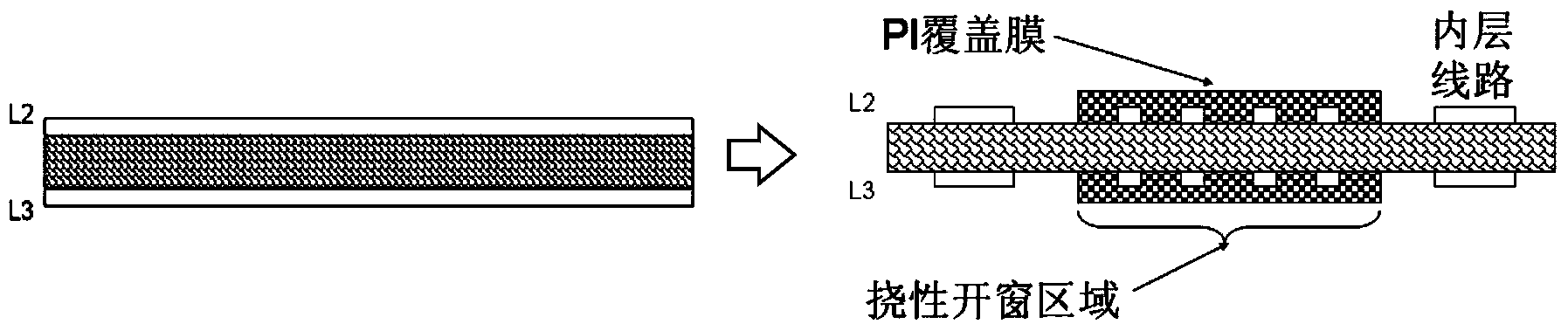

[0032] (1) Fabrication of flexible sub-board (refer to figure 1 ): The flexible board is etched out of the circuit through graphic transfer, and a polyimide cover film is pasted on the flexible area of the flexible board. The polyimide cover film includes an epoxy resin adhesive layer and a PI layer. The epoxy The thickness of the resin adhesive layer is 15.0-75.0 μm, the thickness of the polyimide cover film is 12.7-50.4 μm, and then the flexible sub-board is obtained by pressing, and the pressing parameters are:...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com