Lithium ion battery failure analysis method based on alternating current impedance method

A lithium-ion battery, AC impedance technology, applied in the field of lithium-ion battery failure analysis, can solve problems such as heavy workload, cumbersome analysis process, and many related parameters, and achieve the effect of evaluating life and safety

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

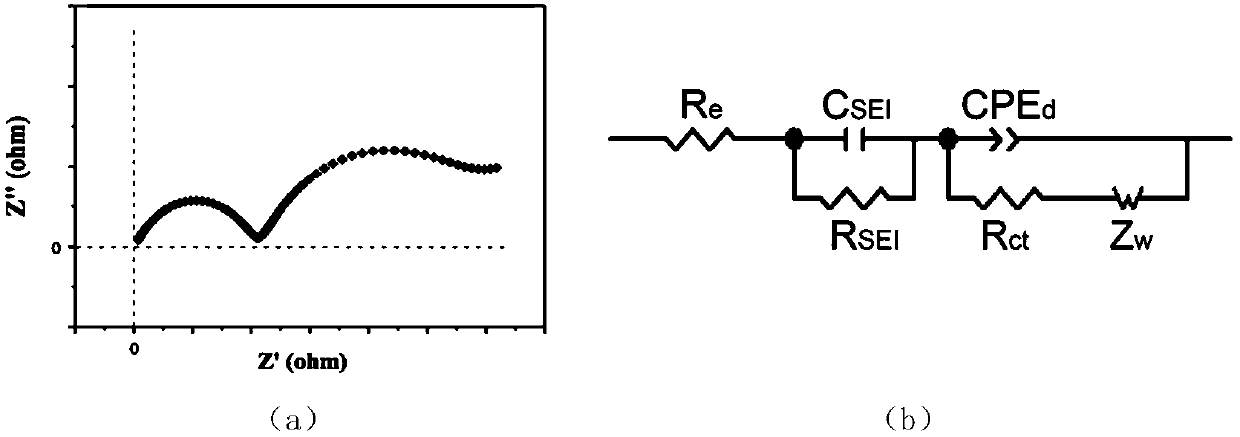

Method used

Image

Examples

Embodiment 1

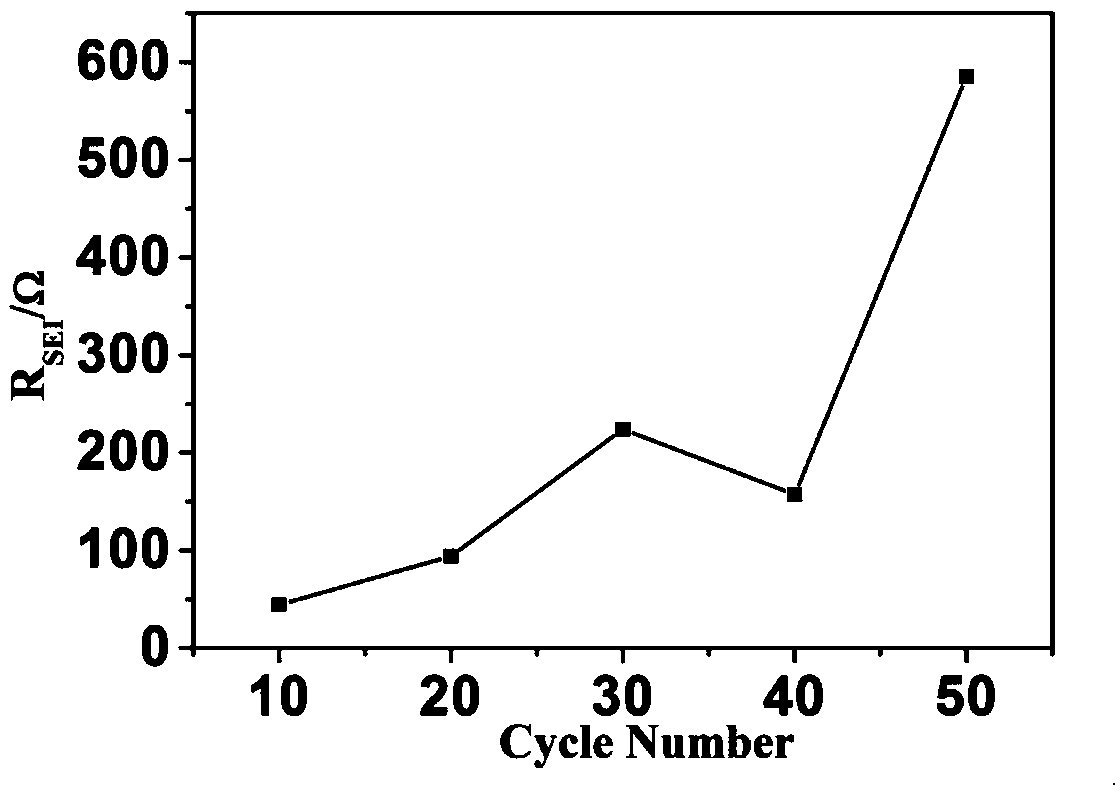

[0027] When the battery is cycled at a rate of 1C, the diffusion resistance R SEI Variation curve with cycle number, such as figure 2 shown, 4.4V overcharge under R SEI The value increases rapidly with the increase of the number of cycles. In the first 30 cycles of the charge-discharge cycle, the surface layer diffusion resistance R SEI It gradually increased from 44.56Ω to 224.2Ω after 10 weeks, indicating that under the overcharge condition of 4.4V cut-off voltage, the surface structure of the material particles changed significantly, the SEI film thickened significantly with the increase of cycle number, and the film resistance increased. And cycle to 40 weeks, R SEI The value becomes 157.3Ω, a sudden decrease compared with 30 weeks, and then R SEI Continue to increase to 585.4Ω at 50 weeks.

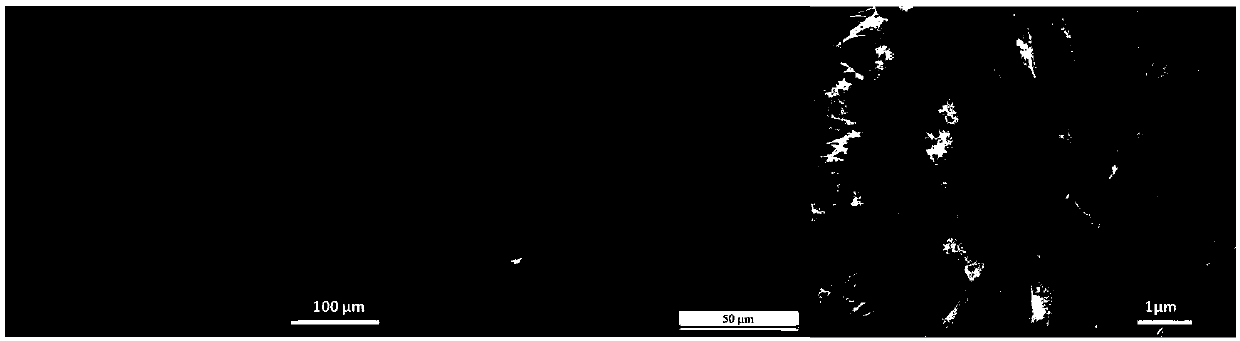

[0028] In order to verify the prediction, for the occurrence of R SEI After the battery at the inflection point where the value begins to decrease is disassembled, observe the n...

Embodiment 2

[0030] When fixing the cathode material LiCoO 2 When the equivalent mass ratio of the negative electrode MCMB microspheres is 1.2:1, the battery is charged and discharged at different cut-off voltages of 4.4V and 4.6V. The result is as Figure 4 As shown, when the battery charging cut-off voltage is set to 4.4V, the diffusion resistance of the surface layer gradually increases from 25.67Ω to 74.04Ω after 10 weeks in the first 30 weeks of the charge-discharge cycle, indicating that the SEI film gradually increases during the cycle. thick, during subsequent cycles R S EI value decreased to 60.55Ω; and when the battery charging cut-off voltage was 4.6V, the diffusion resistance of the surface layer decreased significantly when the cycle reached 20 cycles, indicating that the impedance of the lithium-ion battery increased with the increase of the cut-off voltage in the overcharged state, but R SEI The inflection point at which the value begins to decrease occurs earlier, indic...

Embodiment 3

[0032] When the battery charging cut-off voltage is set to 4.4V, the positive electrode material LiCoO 2 The batteries with the equivalent mass ratio of 1.2:1, 1.3:1 and 1.4:1 to the negative electrode MCMB microspheres were tested. During the charging and discharging cycle of the battery, the diffusion resistance of the surface layer gradually increased (such as Figure 5 shown). When LiCoO 2 R SEI The inflection point appeared at 40 weeks; when the mass ratio was 1.4:1, R SEI The inflection point appears at 30 weeks. It shows that with the increase of the excess ratio of positive electrode materials, the problem of internal short circuit caused by lithium dendrites intensifies, and the time of internal short circuit occurs earlier.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com