Foundation pit support based on real-time feedback

A technology of foundation pit support and real-time feedback, which is applied in foundation structure tests, on-site foundation soil surveys, foundation structure engineering, etc., can solve problems such as potential safety hazards, neglect of importance, and high labor intensity in foundation pits, and achieve The effect of improving the anti-floating performance and bearing capacity, improving the accuracy of vibration monitoring, and improving the accuracy of stress monitoring

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0026] The present invention will be further described in detail below in conjunction with the accompanying drawings and specific embodiments to facilitate a clear understanding of the present invention, but they do not limit the present invention.

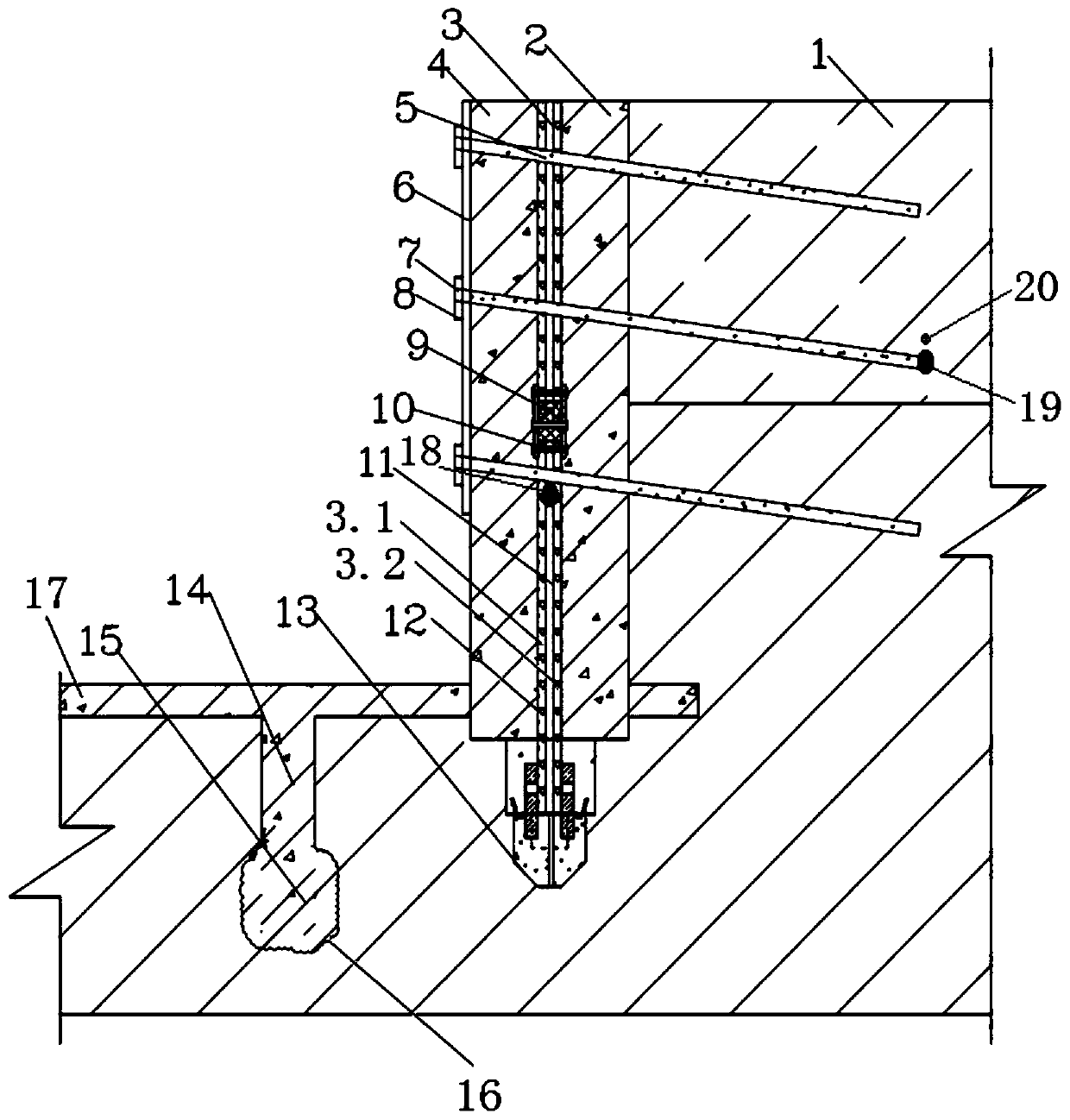

[0027] Such as figure 1As shown, a foundation pit support based on real-time feedback, including main fixed piles 4 and transverse reinforcement rods 5, the main fixed piles 4 are vertically arranged and evenly distributed along the circumference of the side wall of the foundation pit, and the bottom of the main fixed piles 4 is mainly The fixed pile head 13, the bottom of the main fixed pile 4 extends into the soil layer 1 at the bottom of the foundation pit. The side of the main fixed pile 4 away from the foundation pit forms a vertical protective layer 2 . The transverse reinforcing rod 5 passes through the main fixed pile 4 and penetrates into the soil layer 1 of the side wall of the foundation pit downwards. A first vertica...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com