Hydroxylated polyurethane water dispersoid for waterborne soft-feel coating and preparation method thereof

A technology of hydroxyl polyurethane and dispersion, applied in the direction of polyurea/polyurethane coatings, coatings, etc., can solve the problems of poor chemical resistance and poor hand feeling, improve resistance and scratch resistance, improve resistance, and preparation process easy to control effects

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0023] Embodiment 1 prepares elastic polyester diol

[0024] Add 106 parts of diethylene glycol, 180 parts of 1,4-butanediol, 104 parts of neopentyl glycol and 461 parts of adipic acid in the reaction flask with heating device, stirrer, oil-water separator in 1000ml, The initial material was heated to 150°C within 1 hour and then gradually raised to 200°C-210°C within 5 hours under the nitrogen gas, and the condensation reaction was carried out at this temperature. When the acid value is less than 3mgKOH / g, the heating is stopped to obtain elastic polyester diol with a hydroxyl value of about 50mgKOH / g and a relative molecular mass of 1000g / mol, which is stored for future use.

Embodiment 2

[0025] Embodiment 2 prepares hydroxyl-containing polyurethane aqueous dispersion A1~A3

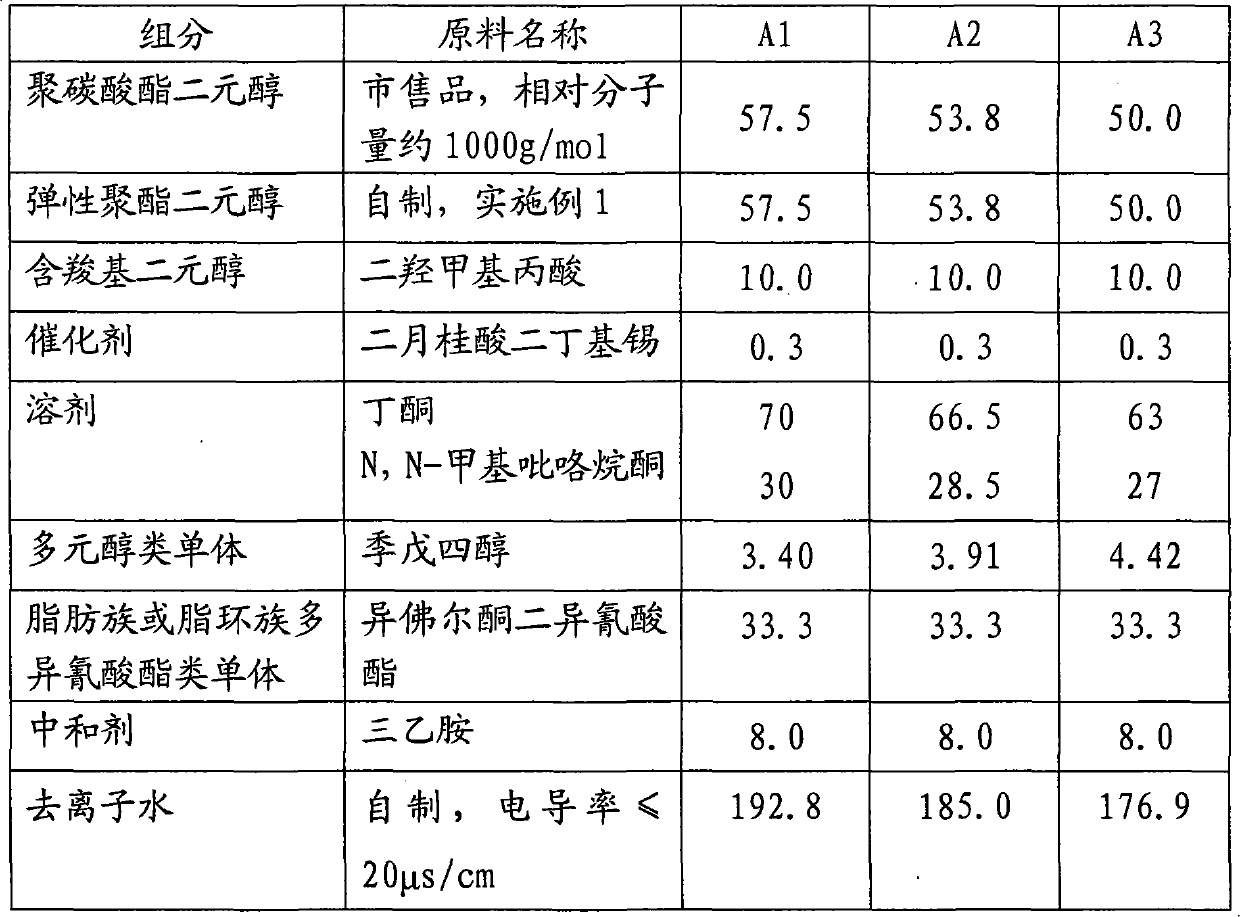

[0026] (1) Formula

[0027] The hydroxyl-containing polyurethane aqueous dispersion used for water-based soft-feeling coatings of the present invention comprises 15 to 25 parts by weight of polycarbonate diol, 15 to 25 parts by weight of elastic polyester diol, and 1 to 5 parts by weight of pentaerythritol , 2 to 5 parts by weight of carboxyl group-containing diols, 10 to 20 parts by weight of aliphatic or alicyclic isocyanate monomers, 0.1 to 1.0 parts by weight of catalysts and solvents are raw materials, and the hydroxyl group-containing polyurethane resin obtained by thermal polymerization, The water dispersion formed after neutralization into salt, self-emulsification, and solvent removal, the specific formula is shown in Table 1.

[0028] Table 1

[0029]

[0030] Note: The commercially available polycarbonate diols used in Table 1 are prepared from 1,5 pentanediol and 1,6 hexan...

Embodiment 3

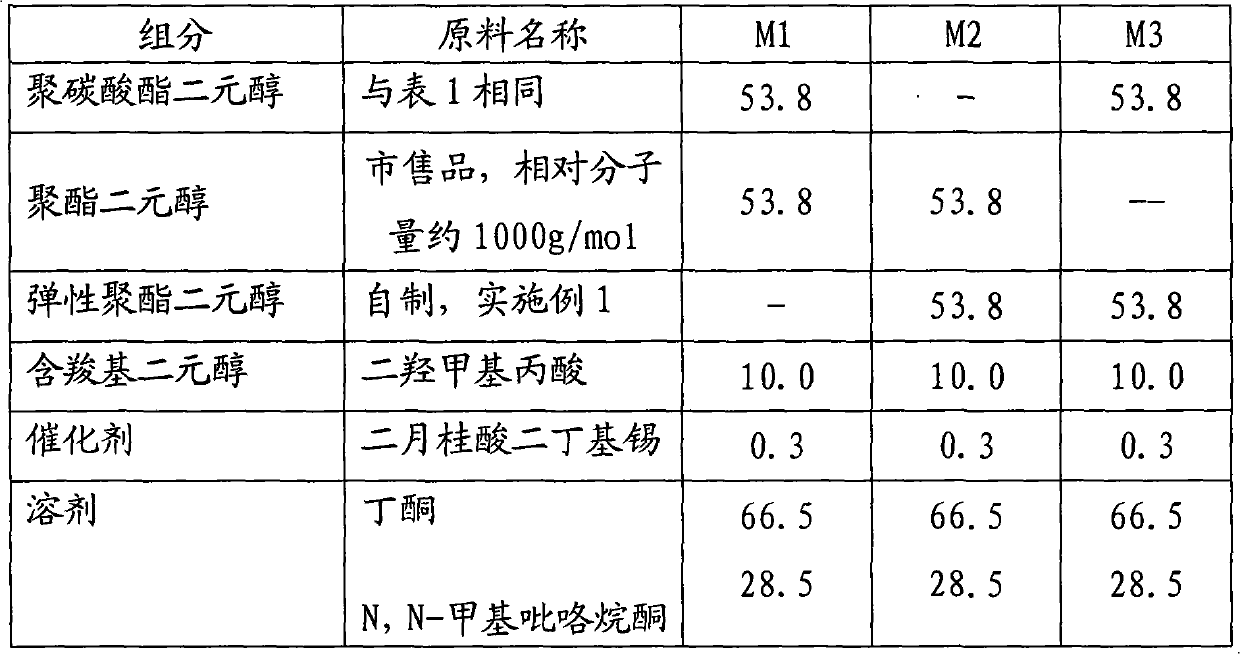

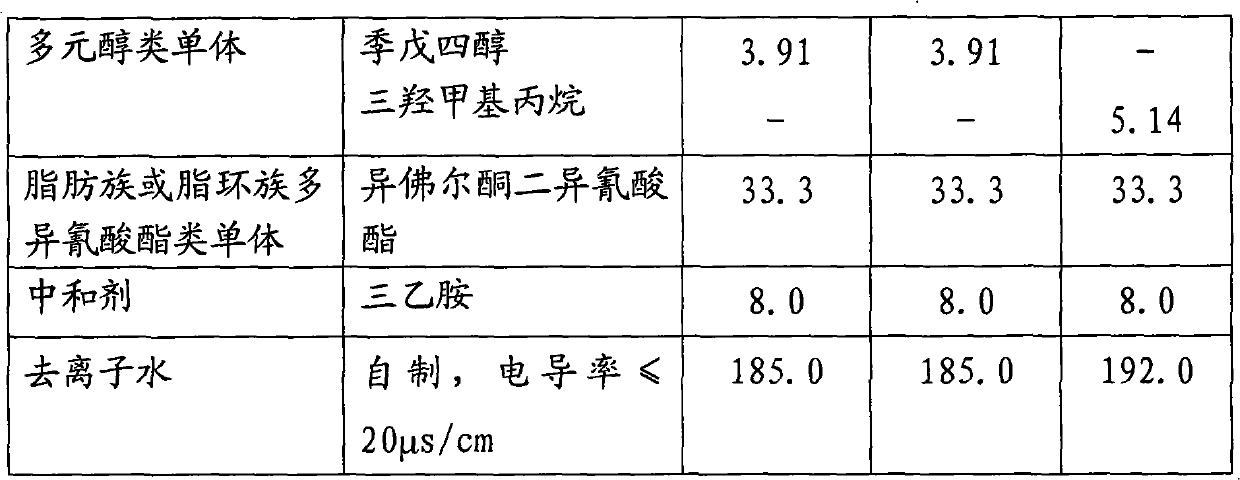

[0040] Embodiment 3 prepares the hydroxyl-containing polyurethane aqueous dispersion M1~M3 for comparative use

[0041] (1) The formula is shown in Table 3

[0042] table 3

[0043]

[0044]

[0045] (2) Concrete preparation steps are as follows:

[0046] Except for using the formula in Table 3, the hydroxyl-containing polyurethane aqueous dispersions M1-M3 were prepared according to the steps in Example 1, and stored for future use.

PUM

| Property | Measurement | Unit |

|---|---|---|

| Hydroxyl value | aaaaa | aaaaa |

| Conductivity | aaaaa | aaaaa |

| Relative molecular mass | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com