Method for manufacturing three-dimensional object by use of spray coating successively

A three-dimensional object, layer-by-layer technology, applied in the field of making three-dimensional objects by layer-by-layer spraying, can solve the problems of low material utilization, opacity, and accumulation of auxiliary process time, and achieve low-cost effects.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0020] The present invention will be further described below in conjunction with the accompanying drawings and embodiments.

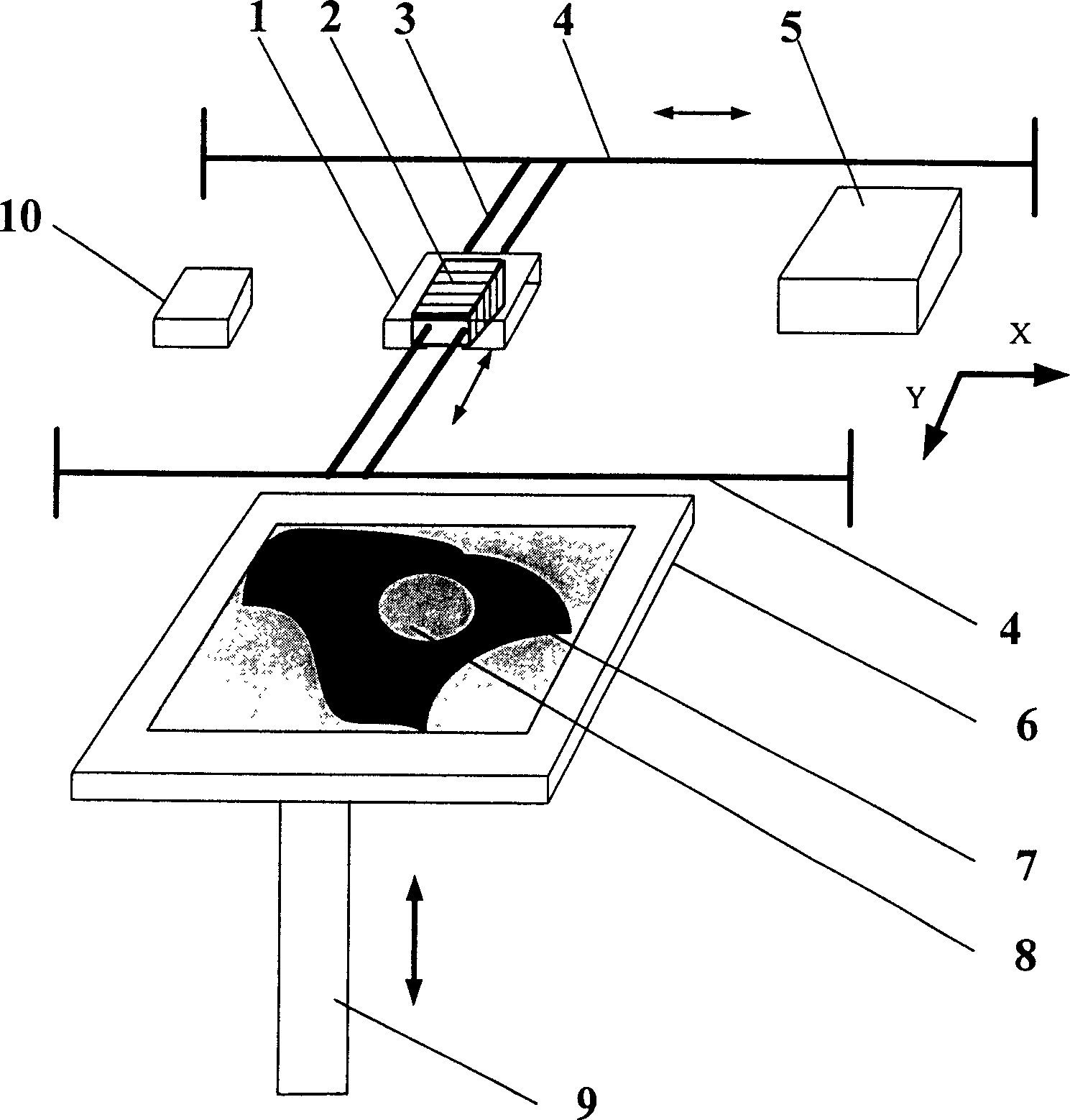

[0021] Such as figure 1 , figure 2 As shown, the specific process of making a three-dimensional object by using the layer-by-layer spraying method to make a three-dimensional object is as follows:

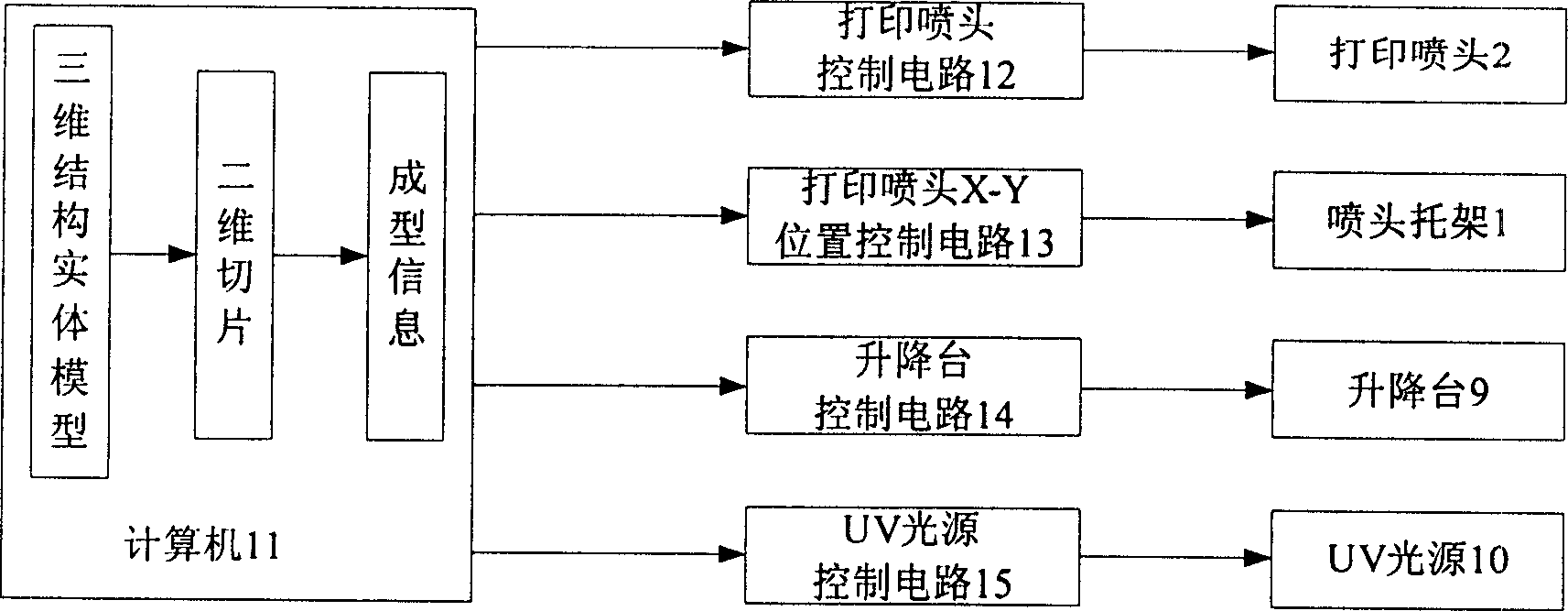

[0022] The 3D CAD model of the 3D structure to be processed is designed by a computer with high-speed computing capability, and the 3D CAD model is sliced and layered to form a series of 2D slices. The thickness of each slice can be the same or different, and the thickness of each slice is 1 μm-300 μm. The computer 11 controls each mechanism to perform coordinated movements according to the forming information of each layer. Specifically, when the production starts, the computer 11 sends the processing information of the first layer to the print head control circuit 12, and the print head control circuit 12 drives one or several print heads in the prin...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com