Rear balanced suspension frame system of heavy-duty car

A suspension system, heavy-duty vehicle technology, applied in the direction of suspension, interconnection system, vehicle components, etc., can solve the problems of insufficient bearing capacity of rear balance suspension, failure of key components of rear balance suspension, loss of manufacturers and users, etc. , to reduce bending deformation, avoid collision and friction, and ensure the effect of rigidity

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0026] The present invention will be further described below in conjunction with the accompanying drawings.

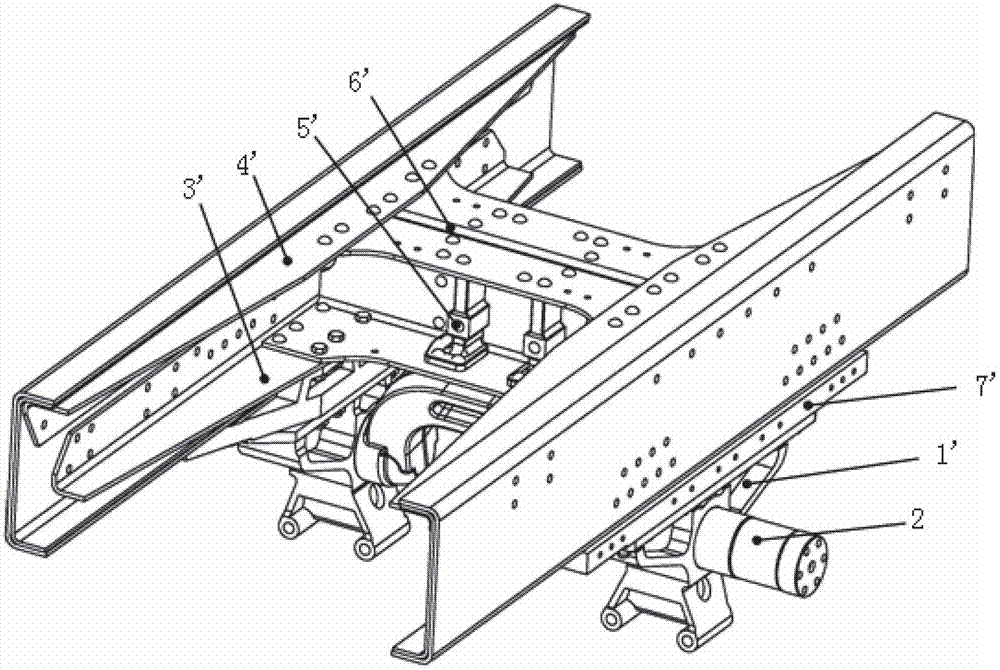

[0027] The invention relates to a heavy-duty vehicle rear balance suspension system, which comprises a cast beam assembly and a balance shaft assembly.

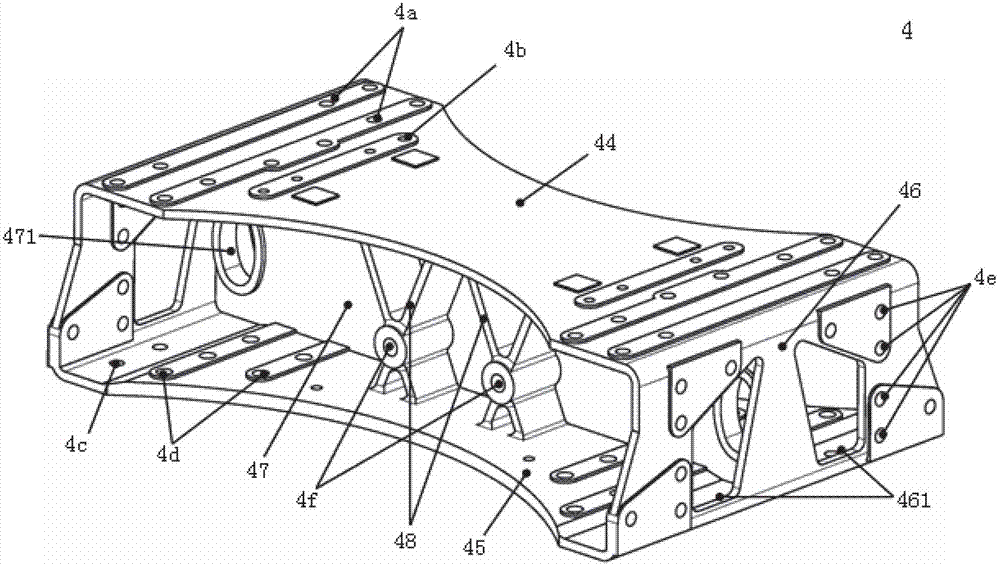

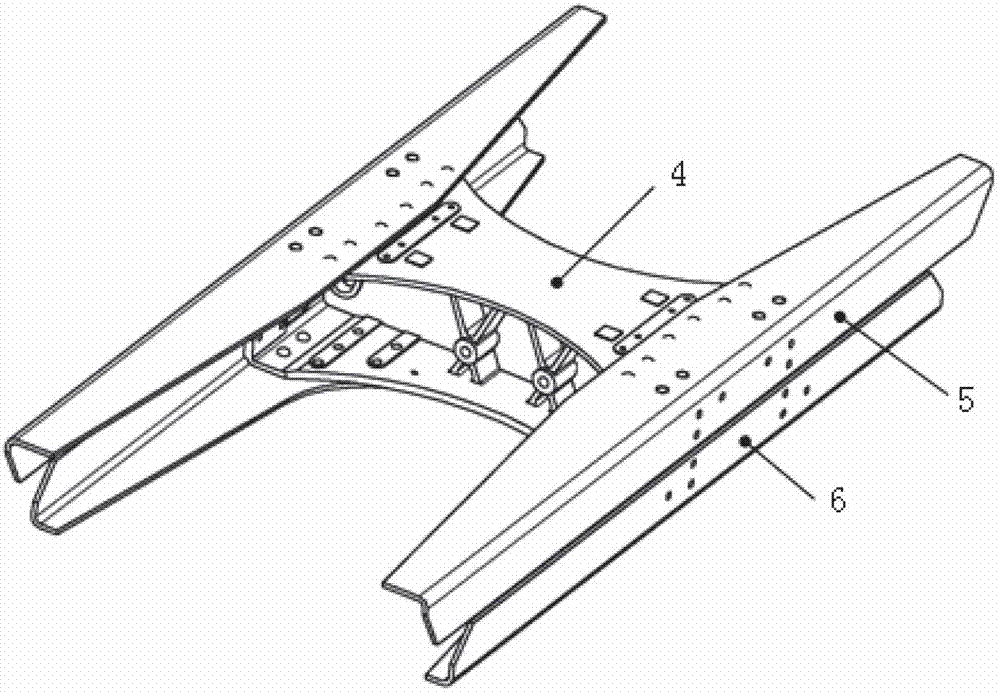

[0028] combine figure 2 and image 3 , The cast beam assembly includes: an integral cast beam 4 , an upper connecting plate 5 , and a lower connecting plate 6 . like figure 2 As shown, the integral cast beam adopts an integral cast structure, including a top plate 44, a bottom plate 45, a side plate 46 connecting the ends of the top plate and the bottom plate and perpendicular to it, and a vertical plate connecting the top plate, the bottom plate and the middle of the two side plates 47. The above arrangement makes the crossbeam form an "I"-shaped section in both the vertical section and the horizontal section perpendicular to the vertical plate 47. Both ends of the top plate 44 are respectively provided with tw...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com