Non-quenched and tempered steel for heavy truck balance shaft and manufacturing method thereof

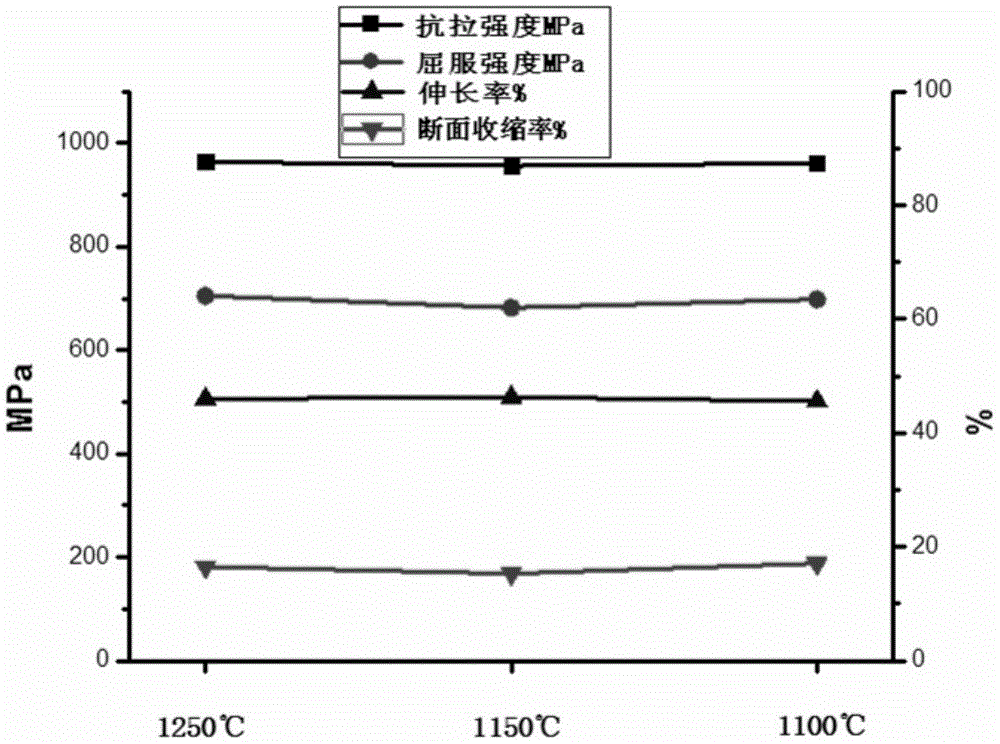

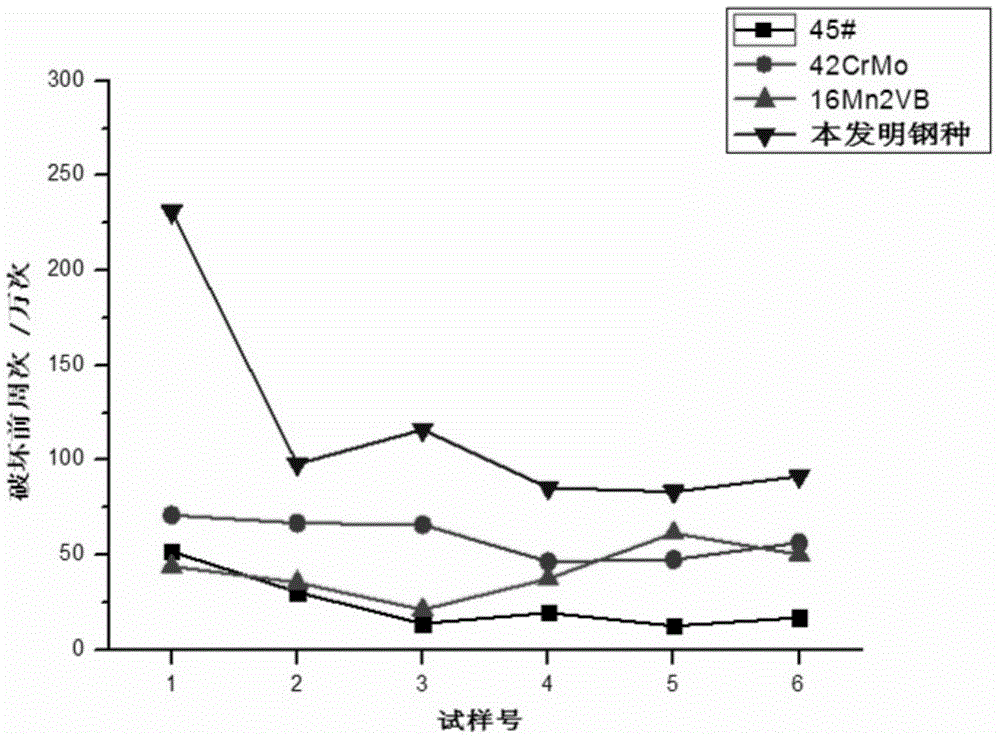

A non-quenched and tempered steel, heavy-duty vehicle technology, applied in the field of automobile manufacturing, can solve the problems of difficult to meet the higher requirements of steel strength and toughness, no application of non-quenched and tempered steel, low toughness, etc., to achieve high fatigue life, good strength. The effect of toughness matching and excellent performance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0036] This embodiment provides a non-quenched and tempered steel for heavy-duty automobile balance shafts. The non-quenched and tempered steel includes the following components by mass percentage: C: 0.24%, Si: 0.33%, Mn: 1.96%, P: 0.007%, S : 0.039%, Cr: 0.49%, V: 0.12%, Ni: 0.03%, Cu: 0.04%, Mo: 0.01%, Ti: 0.012%, Alt: 0.030%, N: 0.014%, O: 0.0015%, H : 0.00005%, Sn: 0.003%, Sb: 0.002%, As: 0.006%, Pb: 0.005%, and the rest is Fe.

[0037] The preparation method of the above-mentioned non-quenched and tempered steel for the balance shaft of heavy-duty vehicles, the process of the preparation method is batching → electric furnace smelting → LF refining → VD vacuum treatment → continuous casting, and the specific operation steps are as follows:

[0038] (1) Prepare ingredients according to the above components and send the ingredients to the electric furnace for smelting. The P content is strictly controlled at 0.008%. The tapping temperature of molten steel is 1610°C. After s...

Embodiment 2

[0045] This embodiment provides a non-quenched and tempered steel for heavy-duty automobile balance shafts. The non-quenched and tempered steel includes the following components by mass percentage: C: 0.24%, Si: 0.32%, Mn: 1.95%, P: 0.007%, S : 0.040%, Cr: 0.51%, V: 0.10%, Ni: 0.04%, Cu: 0.04%, Mo: 0.01%, Ti: 0.015%, Alt: 0.021%, N: 0.015%, O: 0.0008%, H : 0.00008%, Sn: 0.002%, Sb: 0.003%, As: 0.003%, Pb: 0.006%, and the rest is Fe.

[0046] It is characterized in that: the process of the preparation method is batching → electric furnace smelting → LF refining → VD vacuum treatment → continuous casting, and the specific operation steps are as follows:

[0047] (1) Do the ingredients according to the above components and send the ingredients to the electric furnace for smelting. The P content is strictly controlled at 0.009%. The tapping temperature of the molten steel is 1650°C. After smelting, the LF refining furnace is used for refining, and the aluminum feeding wire 2.2 is ...

Embodiment 3

[0054] This embodiment provides a non-quenched and tempered steel for heavy-duty automobile balance shafts. The non-quenched and tempered steel includes the following components in terms of mass percentage: C: 0.24%, Si: 0.31%, Mn: 2.00%, P: 0.005%, S : 0.036%, Cr: 0.50%, V: 0.12%, Ni: 0.06%, Cu: 0.03%, Mo: 0.08%, Ti: 0.015%, Alt: 0.023%, N: 0.014%, O: 0.0010%, H : 0.00010%, Sn: 0.006%, Sb: 0.002%, As: 0.006%, Pb: 0.005%, and the rest is Fe.

[0055] It is characterized in that: the process of the preparation method is batching → electric furnace smelting → LF refining → VD vacuum treatment → continuous casting, and the specific operation steps are as follows:

[0056] (1) Prepare ingredients according to the above components and send the ingredients to the electric furnace for smelting. After smelting, LF refining furnace is used for refining. The P content is strictly controlled at 0.007%. The tapping temperature of molten steel is 1620°C. kg / t, VD is used for vacuum treatm...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Tensile strength | aaaaa | aaaaa |

| Yield strength | aaaaa | aaaaa |

| Tensile strength | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com