Device for removing engine vibration and engine whose stroke characteriscts are variable

A vibration elimination and engine technology, which is applied in the direction of engine components, machines/engines, mechanical equipment, etc., can solve problems such as unavoidable engine enlargement, difficulty in simultaneously reducing engine secondary vibration, secondary vibration, and freedom limit

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

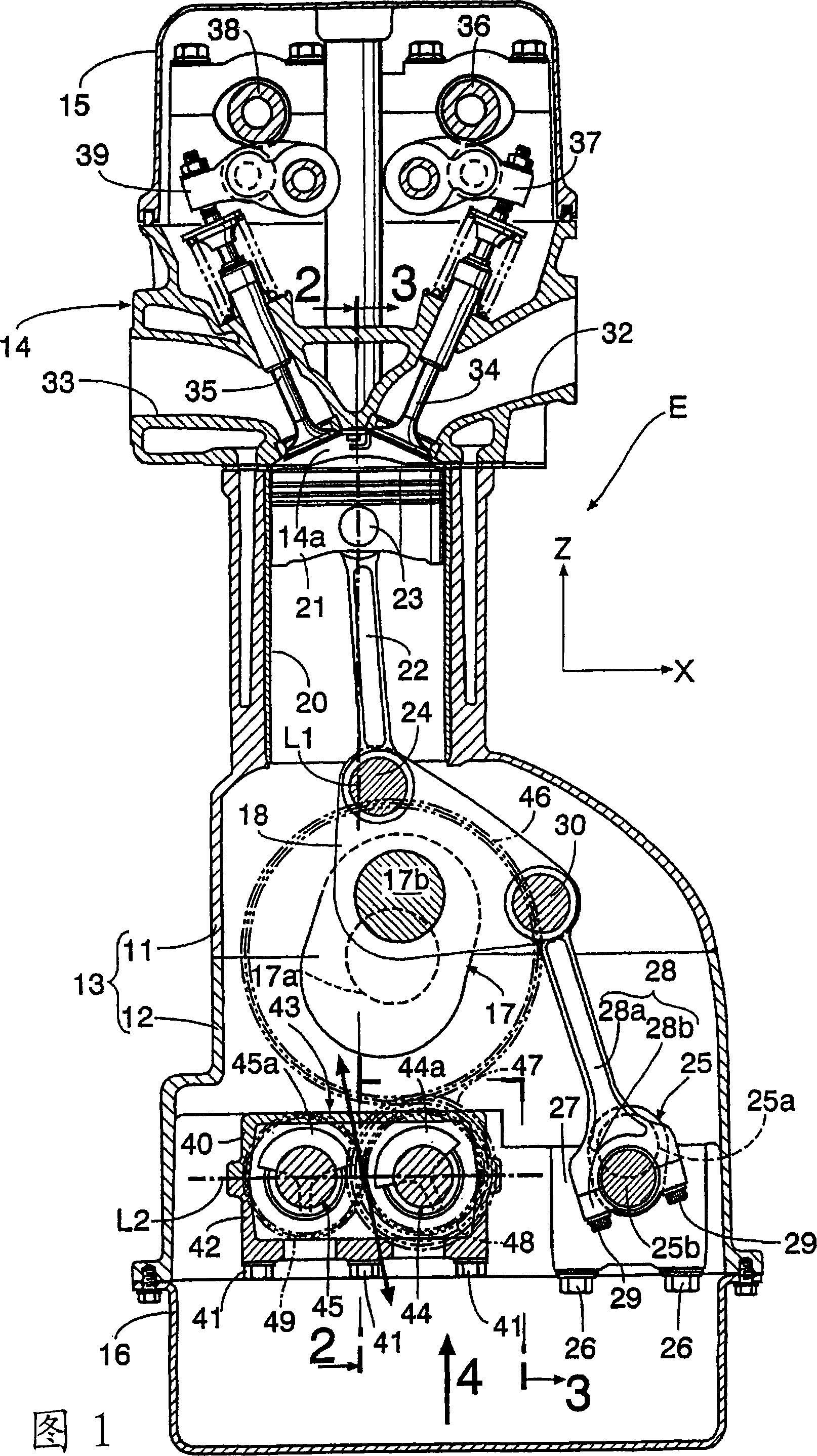

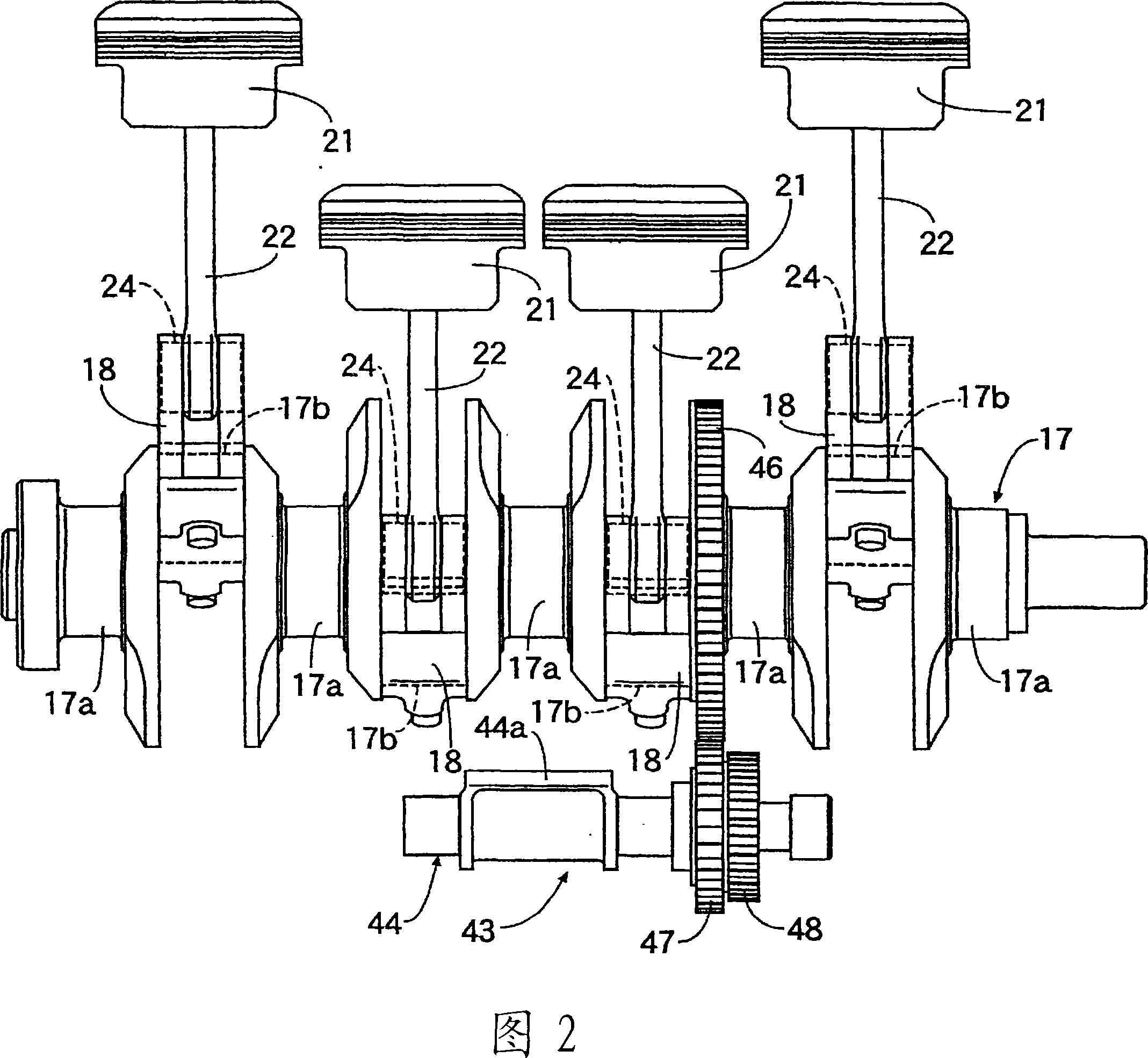

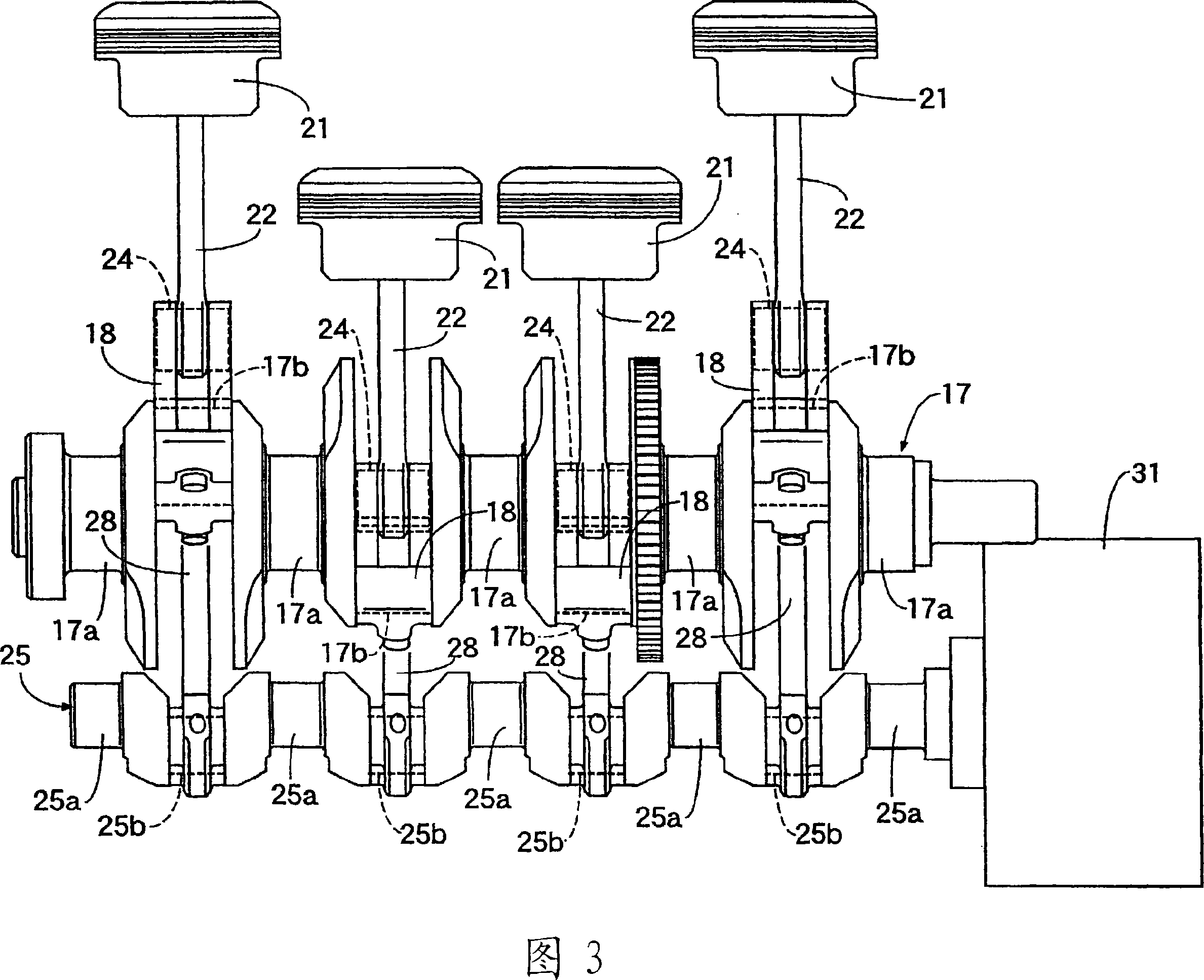

[0126] As shown in Figures 1 to 4, the variable compression ratio engine E is an example of a variable stroke characteristic engine that can change the position of the top dead center or bottom dead center of the piston by arranging a plurality of connecting rods. The engine E has an engine block 13 formed by combining a cylinder block 11 and a crankcase 12, a cylinder head 14 and a cylinder head cover 15 are connected to the upper part of the cylinder block 11, and an oil pan 16 is connected to the lower part of the crankcase 12. . The main journal 17a of the crankshaft 17 is rotatably supported on the interface between the cylinder block 11 and the crankcase 12, and the middle portion of the substantially triangular lower link 18 is rotatably supported on a crankpin journal eccentric from the main journal 17a. (pin journal) 17b.

[0127] The piston 21 is slidably fitted in the cylinder liner 20 provided in the cylinder block 11, the upper end of the upper link 22 (connectin...

Embodiment 2

[0144] Next, a second embodiment of the present invention will be described with reference to FIG. 10 .

[0145] The engine E of the first embodiment is arranged so that the cylinder axis L1 stands vertically, but the engine E of the second embodiment shown in FIG. 10 is arranged so that the cylinder axis L1 is inclined to the intake side by an angle θ. However, a straight line L2 connecting the centers of the first and second balance shafts 44 , 45 of the secondary balancer 43 extends in a horizontal direction parallel to the bottom surface of the oil pan 16 . The phases of the first and second counterweights 44a, 45a are set such that they are directed upwards in the vertical direction or downwards in the vertical direction at the same time, so that the direction of the exciting force generated by the secondary balancing device 43 (refer to arrow) becomes the vertical direction.

[0146] Since the cylinder axis L1 of the engine E is inclined by the angle θ with respect to t...

Embodiment 3

[0148] Next, a third embodiment of the present invention will be described with reference to FIG. 11 .

[0149] The engine E of the second embodiment shown in FIG. 10 is arranged such that the cylinder axis L1 is inclined to the intake side by an angle θ, but the engine E of the third embodiment shown in FIG. 11 is arranged so that the cylinder axis L1 is inclined to the exhaust side. . Since the positional relationship of the secondary balancer 43 with respect to the cylinder axis L1 is the same as that of the second embodiment, the straight line L2 connecting the centers of the first and second balance shafts 44, 45 is more inclined with respect to the vertical direction.

[0150] According to this third embodiment, not only can the vibration of the engine E be effectively eliminated as in the first and second embodiments, but also, compared with the second embodiment, the direction (X direction) of the engine block 13 width, but the size of the cylinder axis L1 direction (...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com