Double-needle-bar warp knitting machine

A double-needle bed warp knitting machine and needle bed technology, which is applied to flat warp knitting machines, warp knitting, knitting, etc., can solve problems such as unfavorable development and increased use costs, and achieve labor and time savings, stable operation, The effect of large amount of needle movement

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0029] The present invention will be described in further detail below in conjunction with the accompanying drawings.

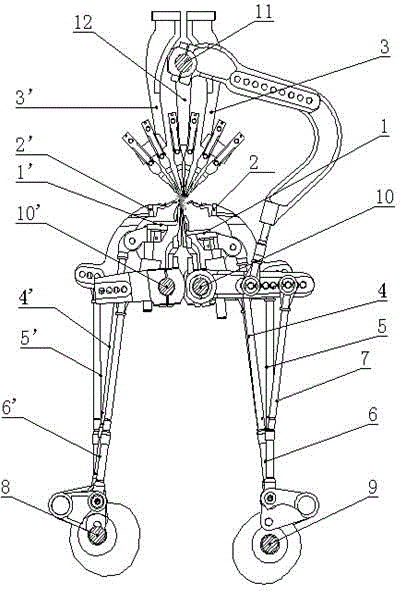

[0030] Such as figure 1 As shown, a double-needle bed warp knitting machine includes a knitting device, a ground comb device and a transmission device; the knitting device includes symmetrical front and rear needle bed parts 1, 1'; front and rear sinker bed parts 2, 2' The ground comb device 3 includes a ground comb holder 3-1, a hair comb cradle 12 connected to the comb bar on the ground comb holder 3-1, and a comb bar on the hair comb cradle 12; the transmission device includes Symmetrical front and rear needle bed transmission mechanisms 4, 4', symmetrical front and rear sinker bed transmission mechanisms 5, 5'; front and rear stripping transmission mechanisms 6, 6'; Shaft 8, No. 2 driving shaft 9.

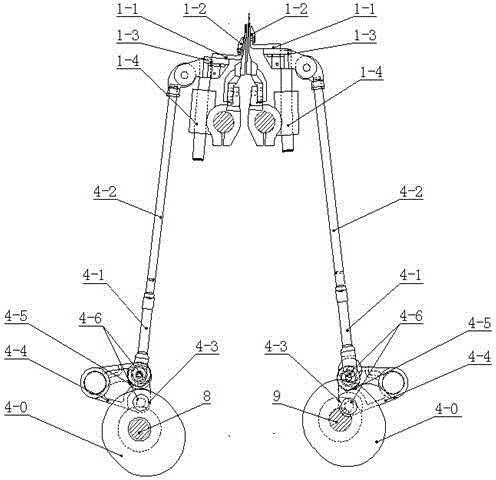

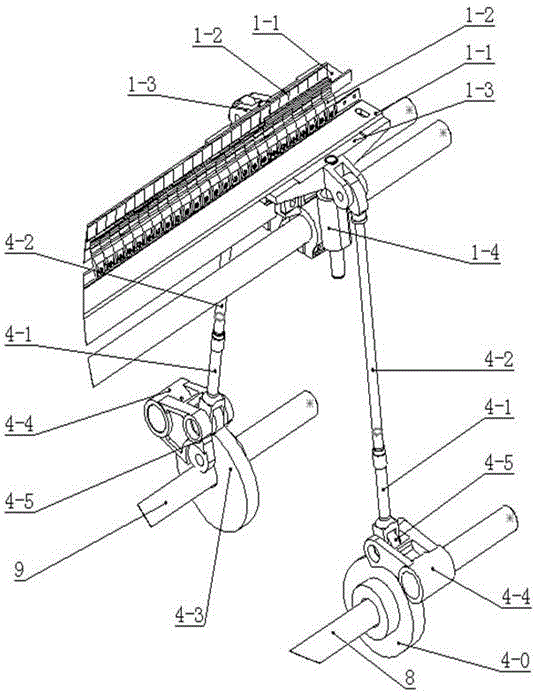

[0031] Such as figure 2 , 3As shown, the parts of the front and rear needle bed parts 1 and 1' each include: needle bed cradles 1-4, 1'-4, needle bed hol...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com