Multi-stage centrifugal pump capable of self-balancing axial force by impeller

A technology of axial force and centrifugal pumps, applied in radial flow pumps, components of pumping devices for elastic fluids, pumps, etc., can solve multi-stage centrifugal pump damage, difficulty in design and manufacture of balance plate devices, damage and other problems, to achieve the effect of low manufacturing cost and solve the problem of axial force damage

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

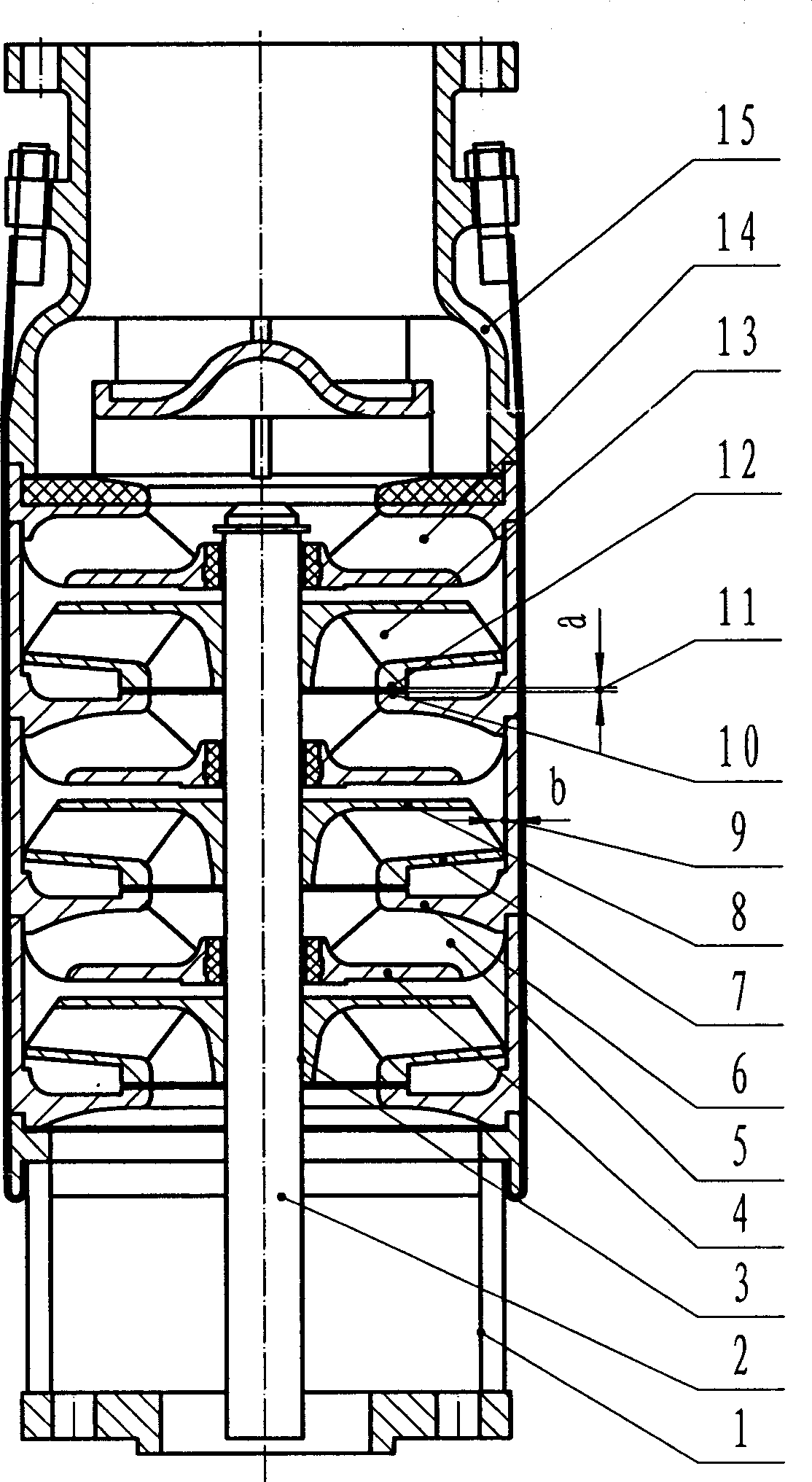

[0013] figure 1 The shown embodiment is a deep well centrifugal pump, which is also a vertical multistage centrifugal pump. It consists of a three-stage impeller (13) and a guide casing (5) together with a water inlet section (1) and a water outlet section (15) ) in series, the diversion case guide vane (14) is an anti-guide vane, the water inlet side has a diversion case front cover (4), the water outlet side has a diversion case rear cover (6), and the impeller has an impeller For the closed impeller of the front cover plate (7) and the impeller rear cover plate (8), the outer diameter of the impeller rear cover plate is smaller than the outer diameter of the impeller front cover plate, and the area of the impeller front cover plate is larger than the area of the impeller rear cover plate, The fit (9) between the outer diameter of the front cover plate of the impeller and the guide shell is clearance fit, the impeller inlet adopts the end face seal, and the impeller is c...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com