Hanging elastic element for heavy all-wheel drive off-road vehicle and design method of element

An elastic element and suspension technology, which is applied to the suspension elastic element for heavy-duty all-wheel drive off-road vehicles and the design field thereof, can solve the problems of no design method, large differences in ride comfort, and poor ride comfort and comfort. Achieving good smoothness

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Benefits of technology

Problems solved by technology

Method used

Image

Examples

Embodiment 1

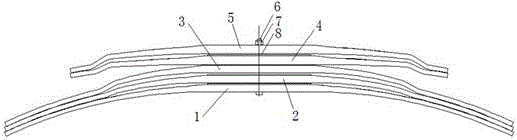

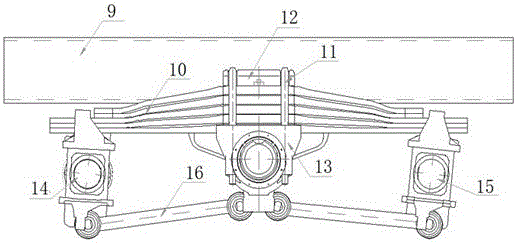

[0040] According to the requirement that off-road vehicles have better comfort under no-load, half-load, full-load and other working conditions, the rear leaf spring adopts the main and auxiliary leaf spring structure with variable stiffness.

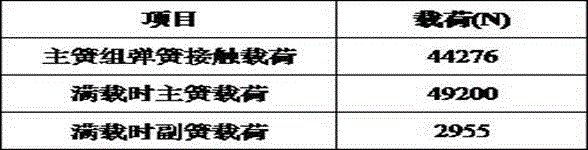

[0041] According to the actual use of off-road vehicles and considering the reliability of the suspension, set the suspension bias frequency to 2.5HZ for a certain load condition with high comfort requirements, such as half-load, and only the main spring works at this time. The suspension bias frequency is also 2.5HZ when the full load condition is set, and the main and auxiliary springs work together at this time. In addition, the stiffness of the suspension at no-load is the stiffness of the main spring of the leaf spring, and the bias frequency is calculated according to the stiffness of the main spring and the actual spring-loaded mass at no-load. For the calculation of the bias frequency and stiffness of the suspension, see formula ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com