Method for manufacturing external coating layer of optical fiber preform rod through sleeve method

An optical fiber preform and outer layer technology, applied in the field of optical fiber manufacturing, can solve the problem of wasting sleeves, etc., and achieve the effects of avoiding waste, improving geometric size, and saving production time.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

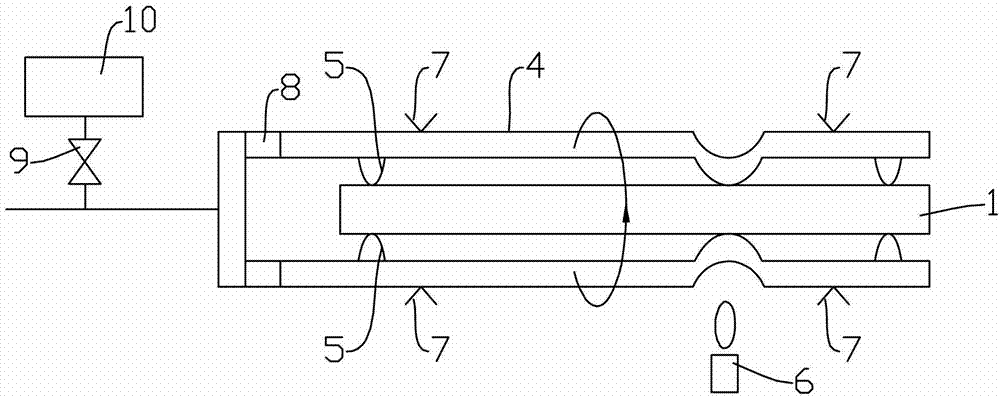

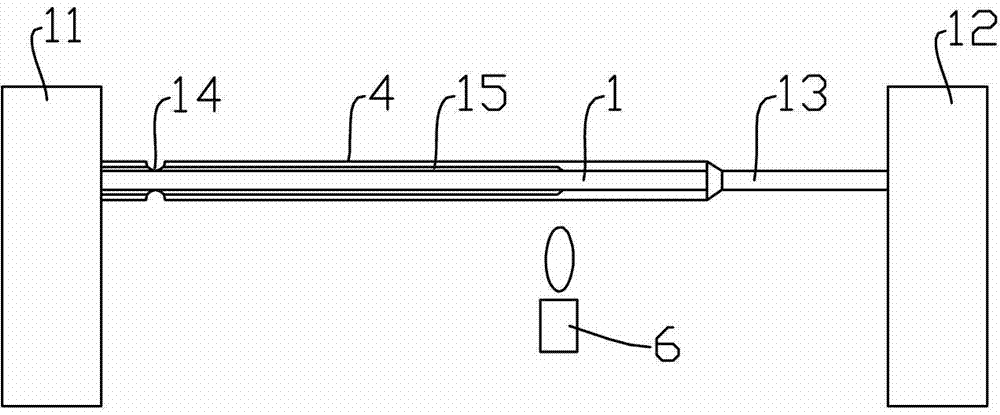

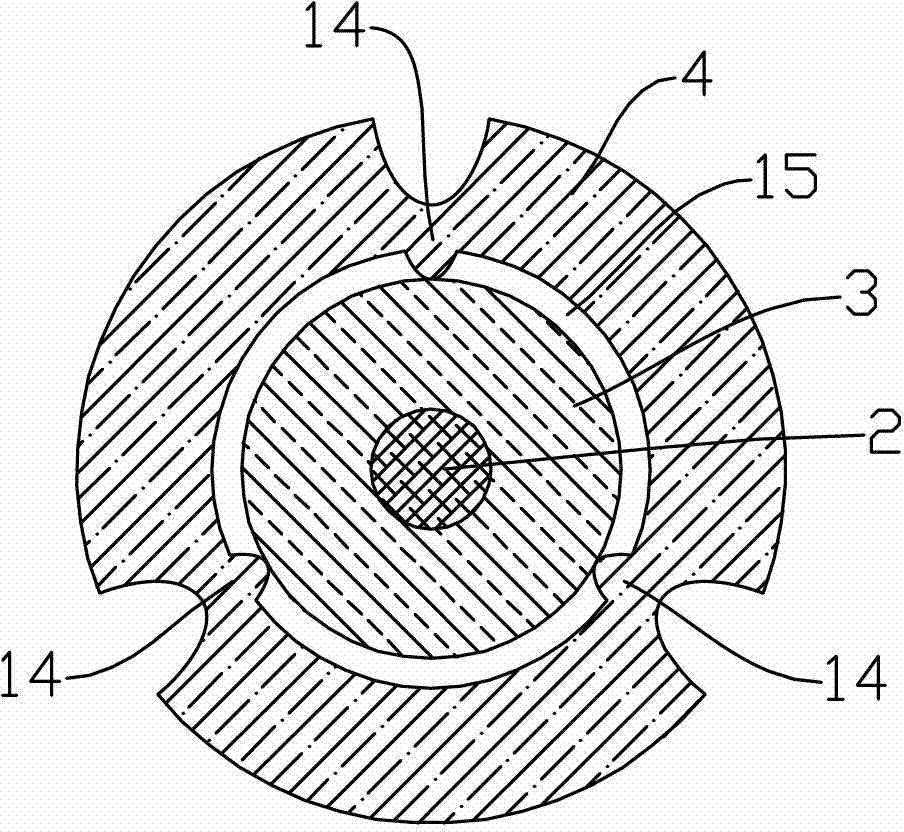

[0034] The mandrel 1 with an outer diameter of 20 mm and a length of 1000 mm is manufactured by a modified chemical vapor deposition method. Then the manufactured mandrel 1 is welded to the auxiliary glass rod 13, and an outer diameter thickened part 19 is arranged at the welding place, and the maximum outer diameter of the outer diameter thickened part 19 is 24mm. The mandrel 1 is flame polished to eliminate surface impurities. The outer diameter of the sleeve pipe 4 processed by pickling is 30mm, the inner diameter is 24mm, and the length is 1000mm. One end is welded to the handle pipe 18, and the handle pipe 18 is installed on the head chuck 71 and connected to the vacuum pump through a rotary joint. The auxiliary glass rod 13 is mounted on the tailstock chuck 72 of the lathe. Then, the whole mandrel 1 is concentrically inserted into the casing 4 until the thickened portion seals one end of the casing, and the gap 15 between the inner wall of the casing 4 and the outer dia...

Embodiment 2

[0036] The mandrel 1 with an outer diameter of 25 mm and a length of 1200 mm is manufactured by plasma chemical vapor deposition. The outer diameter of the sleeve pipe 4 processed by pickling is 32mm, the inner diameter is 27mm, and the length is 1200mm. One end is welded to the handle pipe 18, and the handle pipe is installed on the head chuck and connected to the vacuum pump through a rotary joint. Then the manufactured mandrel 1 is welded to the auxiliary glass rod 13, and an outer diameter thickened part 19 is arranged at the welding place, and the maximum outer diameter of the outer diameter thickened part 19 is 30mm. The auxiliary glass rod 13 is installed on the tailstock chuck 72 of the lathe, and the core rod 1 is flame polished to eliminate surface impurities. Then, the whole mandrel 1 is concentrically inserted into the sleeve 4 until the thickened portion seals one end of the sleeve, and the gap 15 between the inner wall of the sleeve 4 and the outer diameter of th...

PUM

| Property | Measurement | Unit |

|---|---|---|

| diameter | aaaaa | aaaaa |

| length | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com