Organic el display

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Benefits of technology

Problems solved by technology

Method used

Image

Examples

example 1

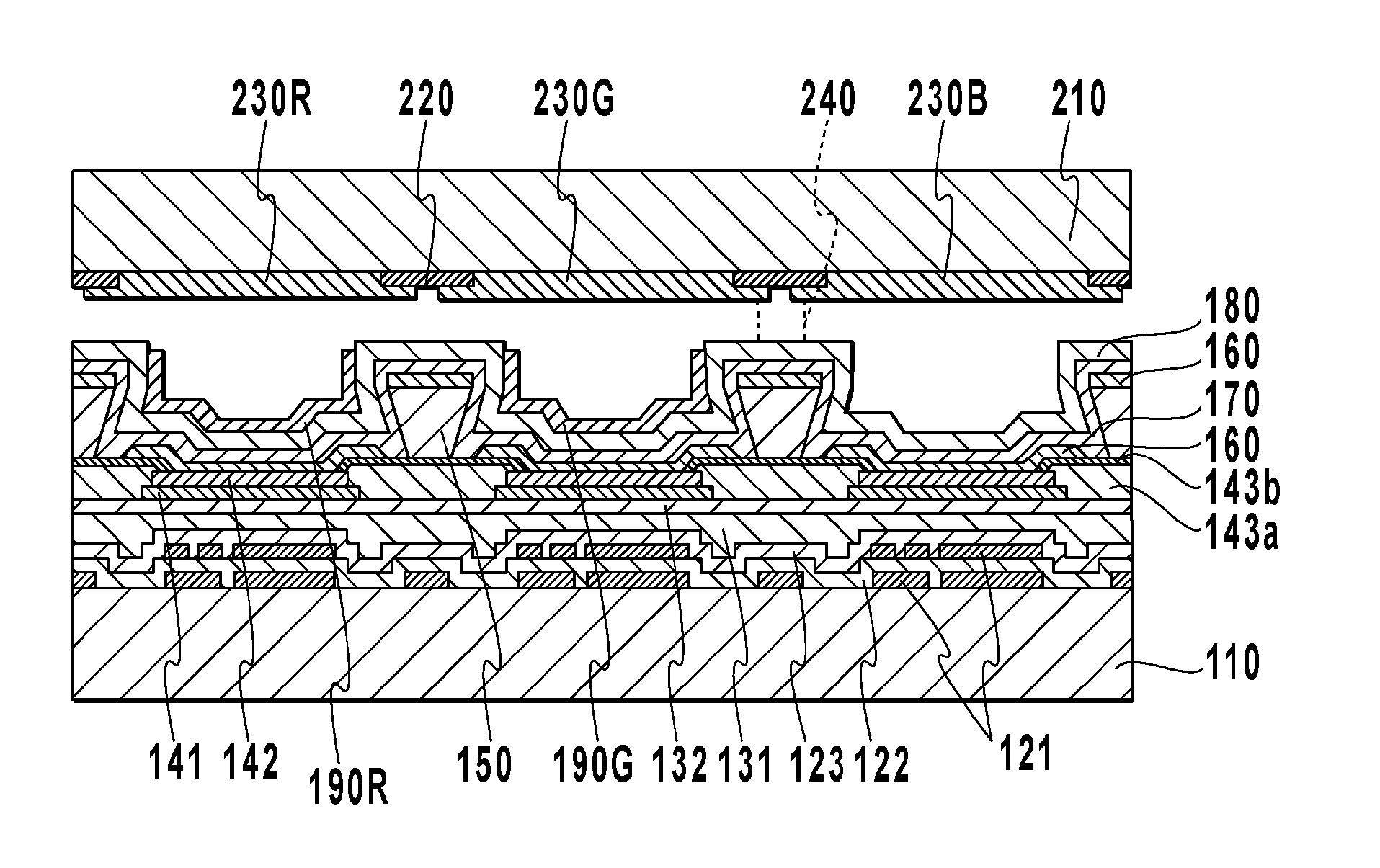

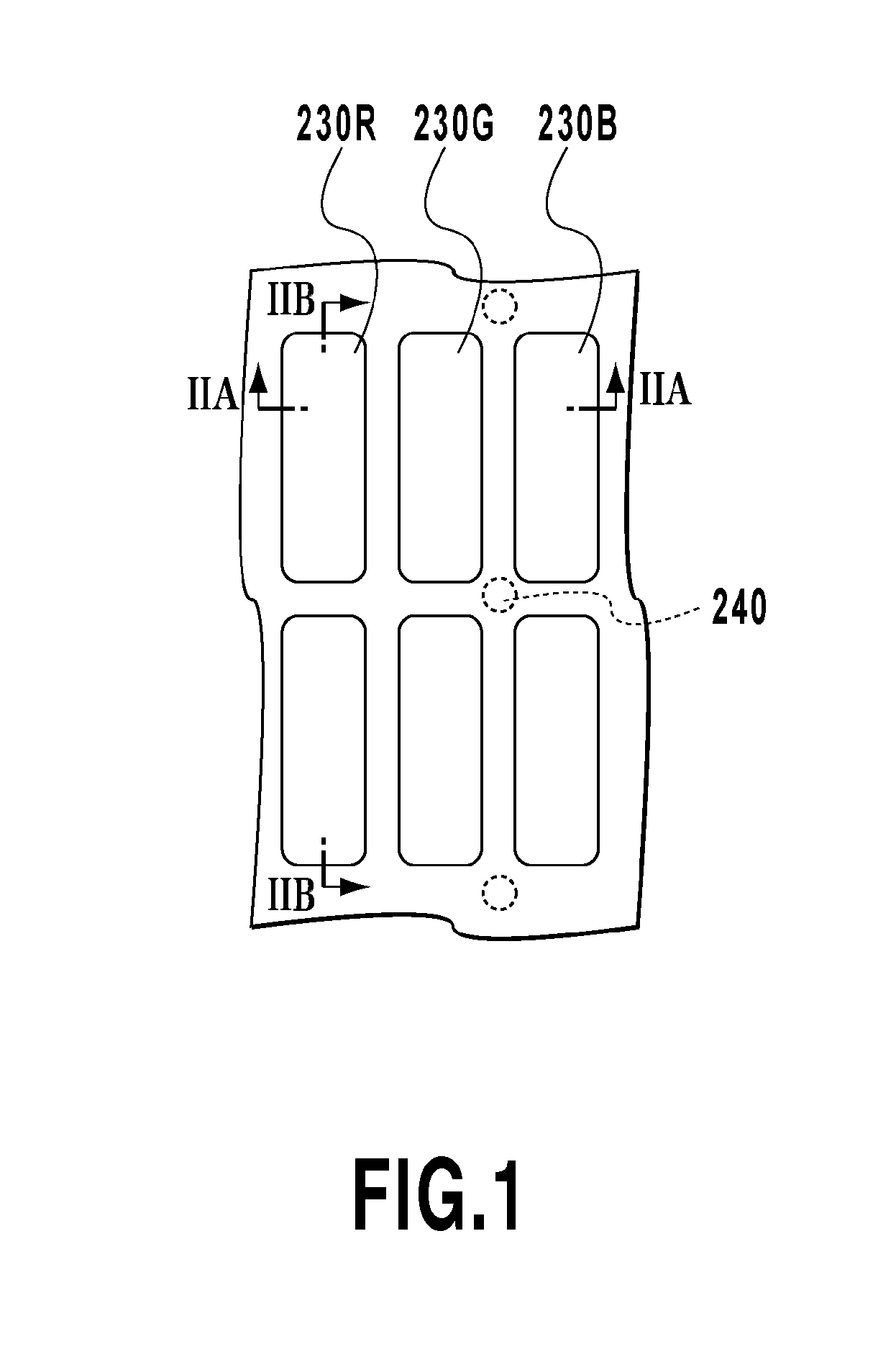

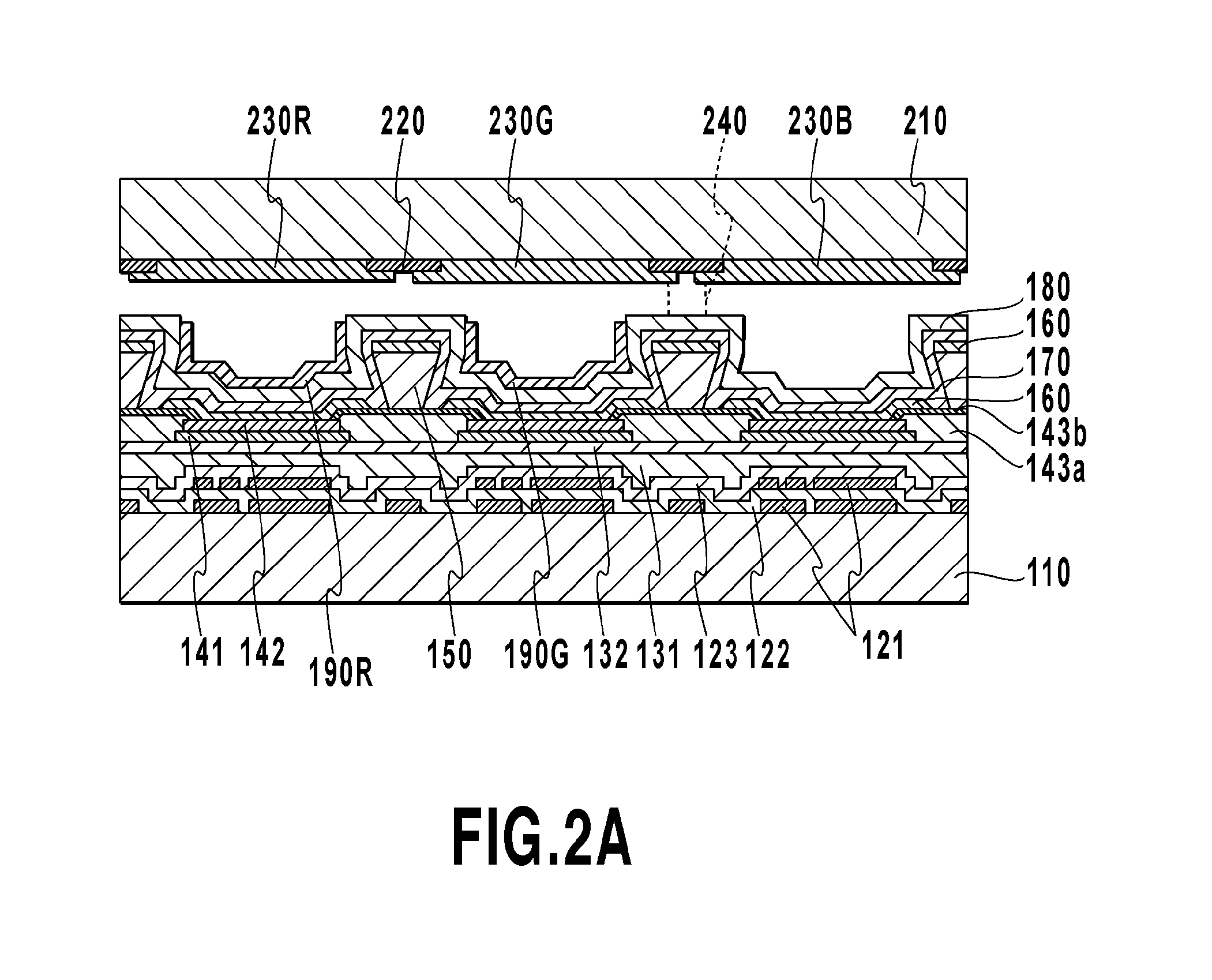

[0067]The present example is an example of the organic EL display of the first embodiment of the present invention. An organic EL display in the present example has a nominal size of 3 inches, and each pixel has a size of 60 μm×180 μm×RGB. Also, a color filter substrate was used, in which the black matrix 220 and three types of color filters 230 were formed on the sealing substrate 210.

[0068]On alkali-free glass having a size of 200 mm×200 mm×0.7 mm (manufactured by Asahi glass, AN-100), the electrically conductive layer 121 (including switching elements and wiring), insulating layer 122, and protective layer 123 for a plurality of display parts were formed. Then, the planarizing layer 131 was formed on the protective layer 123. The planarizing layer 131 was patterned to form a contact hole for connecting the electrically conductive layer 121 with the reflective electrode 142 in each of the sub pixels (light emitting parts) by a photolithography method, wherein the contact hole had ...

example 2

[0086]The present example is another example of the organic EL display of the, first embodiment of the present invention. An organic EL display in the present example has a nominal size of 3 inches, and each pixel has a size of 60 μm×180 μm×RGB. Also, a color filter substrate, in which the black matrix 220 and three types of color filters 230 were formed on the sealing substrate 210, was used.

[0087]First, in the same procedure as that in Example 1, the layers including and below the inorganic passivation layer 132 were formed.

[0088]Then, the separation wall 150 made of Cu was formed by a Cu plating method. The separation wall 150 was constituted of the plurality of striped parts extending longitudinally and the plurality of striped parts extending transversely. The separation wall 150 had the openings in the locations corresponding to the respective light emitting parts. Further, each of the striped parts constituting the separation wall 150 had a rectangular cross-sectional shape h...

example 3

[0092]The present example is an example of the organic EL display of the second embodiment of the present invention. An organic EL display in the present example has a nominal size of 6 inches, and each pixel has a size of 100 μm×300 μm×RGB. Also, a color filter substrate was used, in which the black matrix 220 and three types of color filters 230 were formed on the sealing substrate 210.

[0093]First, in the same procedure as that in Example 1 except that the size of each pixel was changed, the layers including and below the inorganic passivation layer 132 were formed. Subsequently, an IZO film was formed by a sputtering method and patterned in the same procedure as that in Example 1, to form the underlying layer 141 constituted of the plurality of parts separated for each of the sub pixels, and the underlying layer 144 for auxiliary wiring constituted of the plurality of striped parts having a width of 16 μm in gaps between transversely adjacent sub pixels. Each of the striped parts...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com