Selective etching epitaxial micro-led chip and its design and fabrication method

A chip and area selection technology, applied in the fields of semiconductor/solid-state device manufacturing, semiconductor devices, electrical components, etc., can solve the problems of reducing the performance of Micro-LED display, RGB three-primary color crosstalk, etc., to improve color conversion efficiency, avoid damage, reduce The effect of non-radiative recombination efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

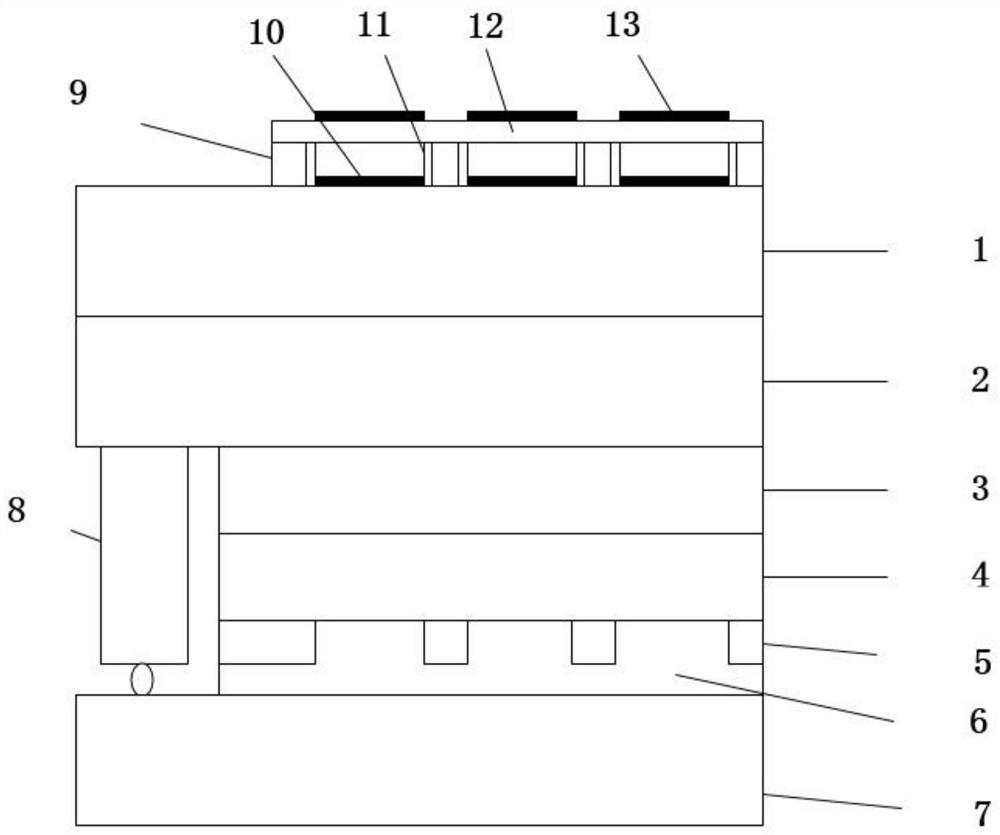

[0035] Provided is a selective etching epitaxy reduction crosstalk full-color Micro-LED array design and preparation method, which specifically includes the following steps:

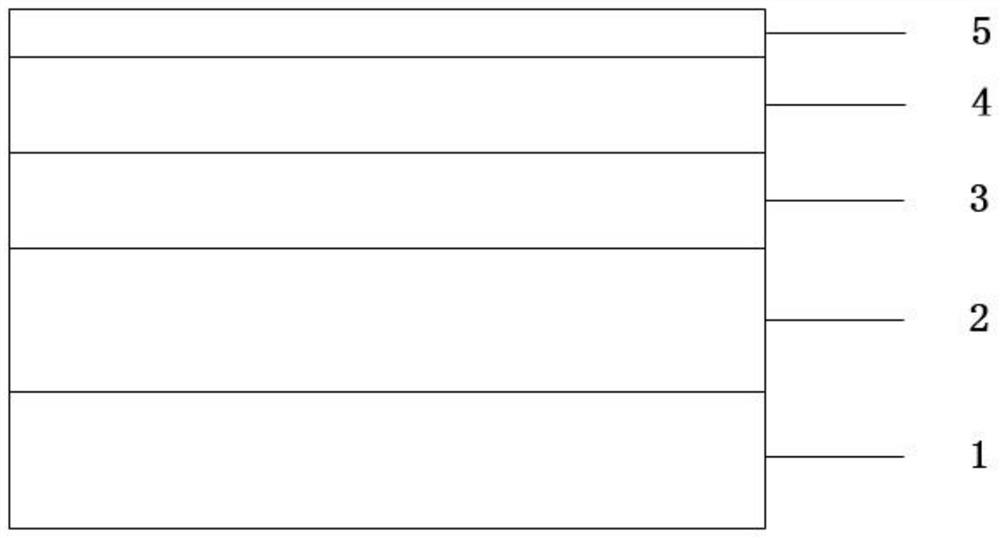

[0036] S1. Provide a sapphire substrate 1 with a thickness of 200 μm, and use MOCVD technology to sequentially grow an n-GaN layer 2 with a thickness of 3 μm and 5 pairs of Al with a total thickness of 65 nm on the sapphire substrate 0.47 Ga 0.53 N(10nm) / Al 0.57 Ga 0.43N (3nm) multi-quantum well layer 3, p-GaN layer 4 with a thickness of 3 μm;

[0037] S2. On the epitaxial structure obtained in S1, the epitaxial structure includes n-GaN layer, multiple quantum well layer, p-GaN layer and deposited SiO 2 Insulating layer, using PECVD technology to deposit SiO with a thickness of 5 μm on p-GaN 2 insulating layer 5, such as figure 2 shown;

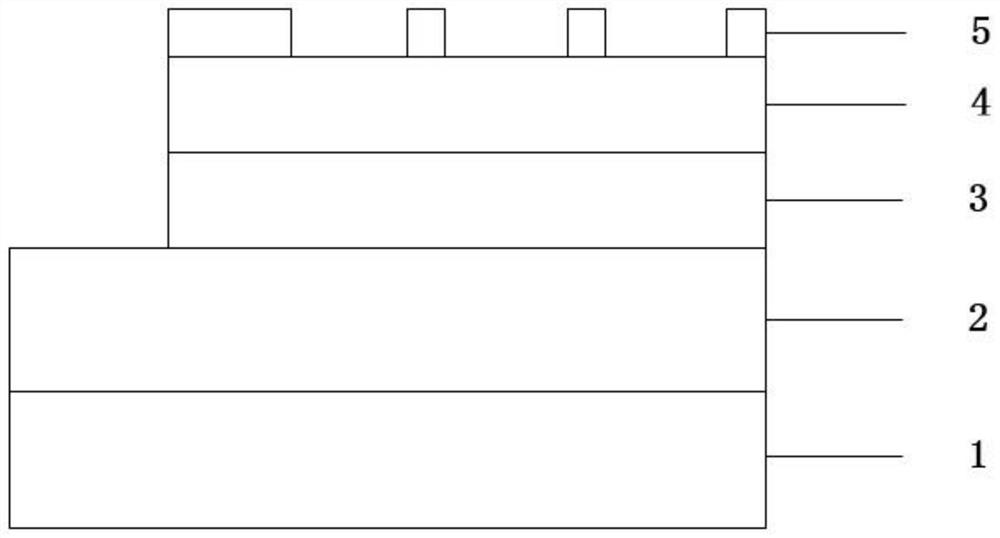

[0038] S3. Use photolithography to transfer the pattern on the mask to SiO 2 insulating layer, and then use ICP technique on SiO 2 Selective etching is perform...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com