Core-shell-structure ZrB2-SiC/Si composite powder and preparation method thereof

A technology of composite powder and core-shell structure, applied in coatings and other directions, can solve the problems that the coating is difficult to meet the requirements of high temperature thermal protection performance, the two phases in the coating cannot be uniformly dispersed, and the SiC composition is insufficient. Industrial production, promoting the improvement of coating performance, and the effect of low equipment requirements

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

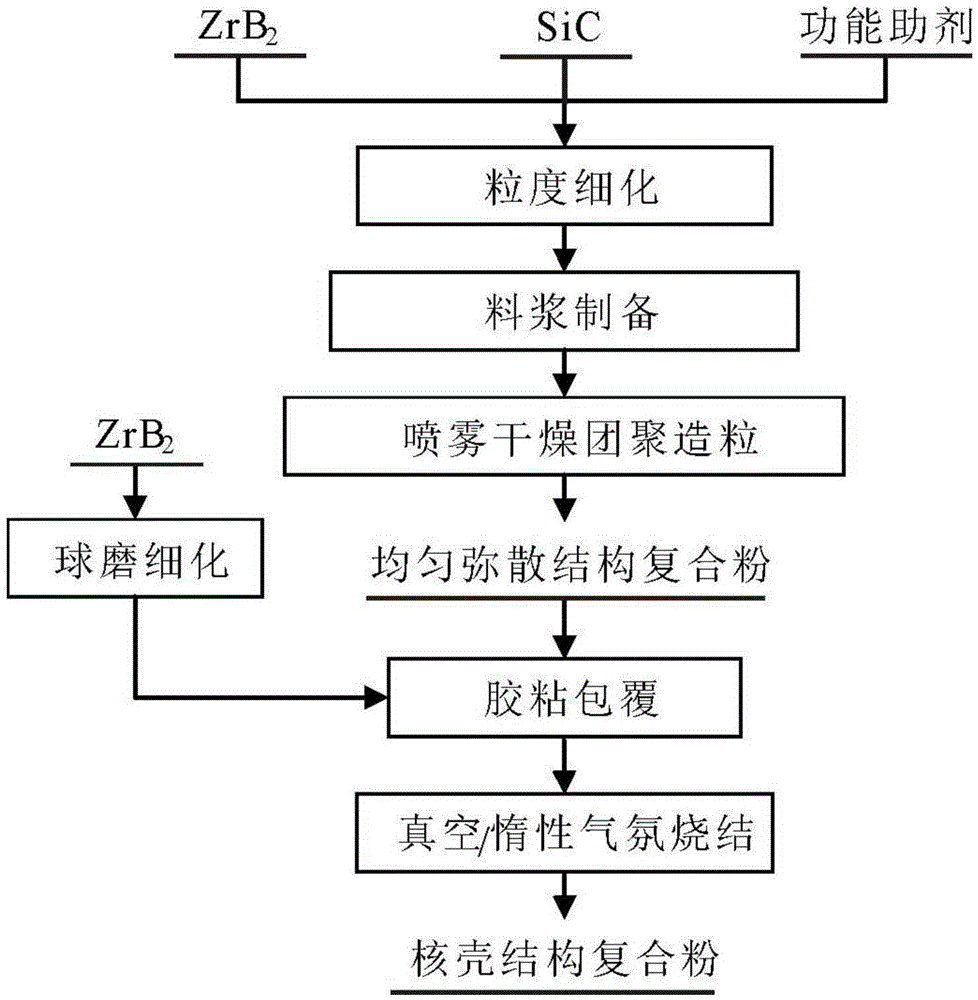

[0042] The present invention provides a kind of above-mentioned ZrB with core-shell structure 2 -The preparation method of SiC / Si composite powder, specifically comprises the following steps:

[0043] 1): The particle size refinement of each original powder:

[0044] After the powder is refined, the primary primary particle size of each primary powder is less than 5 μm;

[0045] 2): Powder spray drying agglomeration granulation:

[0046] The refined powder is weighed according to the mass percentage of the nucleus, and used as spray granulation;

[0047] The refined powder is mixed with an organic binder to form a slurry for ball milling, and then the slurry after ball milling is spray-dried and agglomerated in a spray drying tower. 60-100ml / min; the inlet temperature is between 250-350°C, the outlet temperature is between 100-220°C, and after spray drying, solid aggregate particles containing organic binders are obtained, namely ZrB 2 - SiC composite powder;

[0048] 3):...

Embodiment 1

[0067] In the core-shell structure composite powder prepared in this example: the shell is completely ZrB 2 , accounting for 15wt% of the total powder weight, ZrB in the inner core 2 and SiC composition percentages were 60wt% and 25wt%.

[0068] The core-shell structure ZrB in the present embodiment 2 Pack ZrB 2 -SiC homogeneously dispersed composite powder is prepared by the following method, including the following steps:

[0069] 1) The particle size refinement of each original powder:

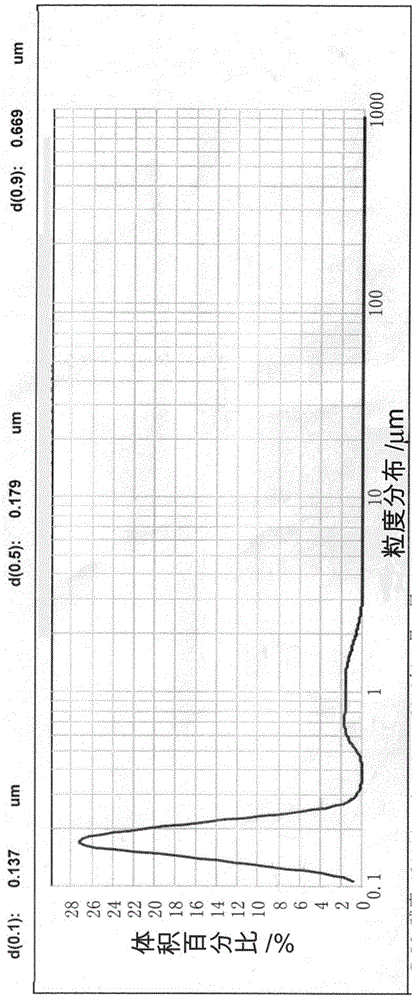

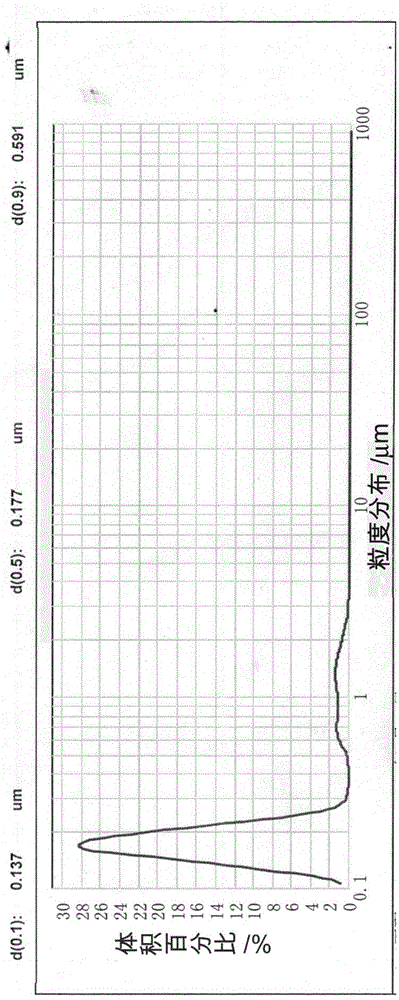

[0070] Using ball milling process, in the ball mill, add ZrB respectively 2 , SiC, ZrO 2 Grinding balls and water, set the mass ratio of grinding balls: powder: ball milling medium water at 7.5:1:2.5, the ball milling speed is set to 300r / min, the ball milling time is 6h, and the ball milling is dried at 120°C for 10h in vacuum.

[0071] After ball milling and drying, ZrB 2 and the particle size distribution diagrams of SiC, respectively, as figure 2 with image 3 shown.

[0072]...

Embodiment 2

[0082] The core-shell structure composite powder prepared in this example: the shell is completely ZrB 2, accounting for 15wt% of the total composition of the powder, ZrB in the core 2 and Si composition percentages were 77.3wt% and 7.7wt%.

[0083] The core-shell structure ZrB in the present embodiment 2 Pack ZrB 2 -Si homogeneously dispersed composite powder is prepared by the following method, including the following steps:

[0084] 1) The particle size refinement of each original powder:

[0085] Original ZrB 2 , Si, etc. are respectively added to the jet milling classifier and processed by jet milling method, the crushing pressure is: 0.8Mpa, and the airflow speed can reach supersonic speed 400m / s at this time.

[0086] 2) Spray drying and agglomeration granulation of powder:

[0087] Weigh the refined powder according to the required mass percentage of the nucleus. Spray granulation virgin powder ZrB 2 , Si and organic binder solution are mixed to form a slurry f...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

| particle size | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com