Conductive zirconia revolving target and preparation method thereof

A zirconia, rotating target technology, applied in metal material coating process, ion implantation plating, coating and other directions, can solve the problems of increasing production steps, difficult to meet flexible control, increasing target cost, etc., to achieve low cost , The production process is simple and convenient, and the conductivity is good.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

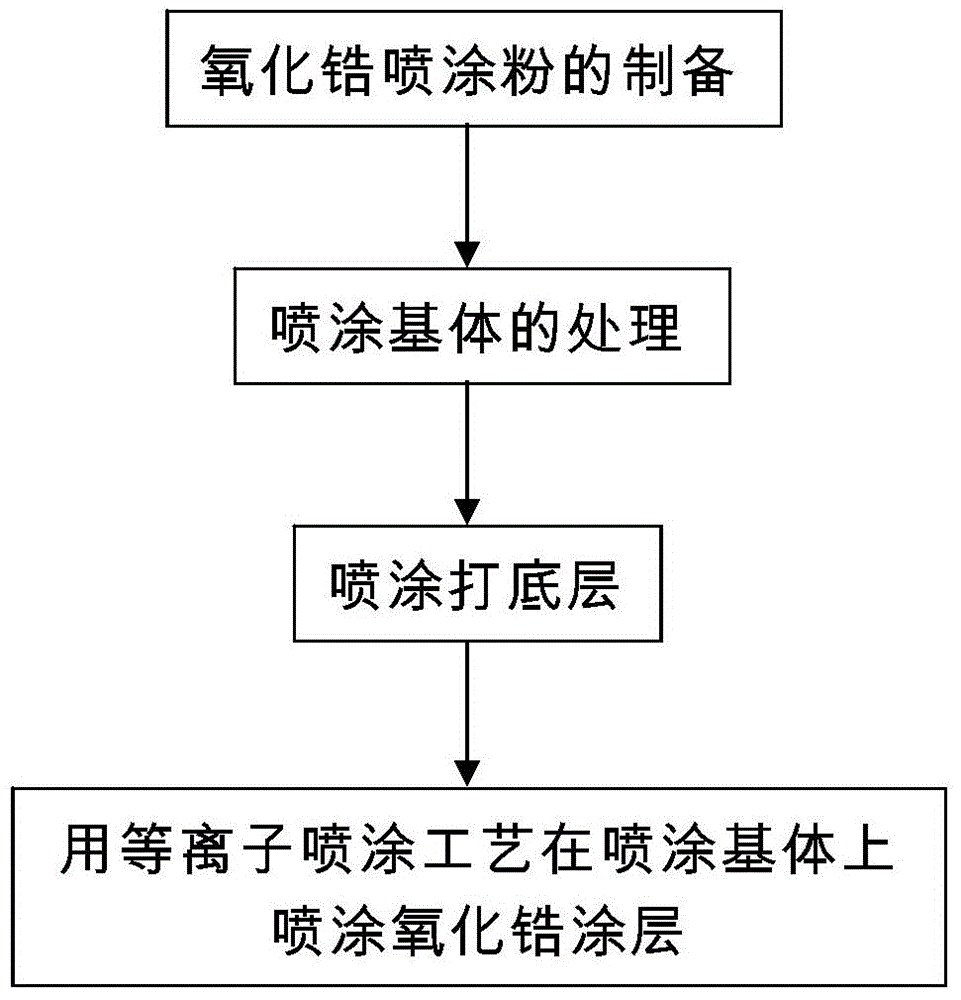

[0023] see figure 1 , a method for preparing a conductive zirconia rotating target provided by the present invention comprises the following process steps:

[0024] Preparation of zirconia spraying powder: After mechanically mixing zirconia powder with a mass percentage of 93-98%, a purity of not less than 99.95wt%, and a particle size of 1-5um with carbon powder with a mass percentage of 2-7%, the Sinter in a hydrogen atmosphere at 1500-1700°C for 6-10 hours, and then spray dry to obtain 100-400 mesh spray powder.

[0025] Spraying substrate treatment: use cleaning and mechanical grinding to remove surface oil stains and oxide layers, and then use sandblasting to make the surface of the substrate reach a certain roughness to increase the bonding strength between the substrate and the coating.

[0026] Spraying base layer: Spray a layer of nickel-clad aluminum (Ni / Al), nickel-chromium (Ni / Cr), nickel-chromium-aluminum (Ni / Cr / Al) or Nickel-chromium-aluminum-yttrium (Ni / Cr / Al / ...

Embodiment 1

[0033] A zirconia target material with a thickness of 4mm is sprayed on a stainless steel tube with an outer diameter of 133mm and a length of 3191mm.

[0034] After mechanically mixing zirconia powder with a mass percentage of 98 wt%, a purity of not less than 99.5 wt%, and a particle size of 1um and a mass percentage of carbon powder with a mass percentage of 2 wt%, it was sintered at 1500°C for 6 hours with hydrogen, and then the sintered The powder is spray-dried and granulated to obtain a zirconia spray powder of 100-225 mesh.

[0035] Use absolute ethanol to remove oil stains on the surface, and sandblast to make the surface of the substrate reach a certain roughness.

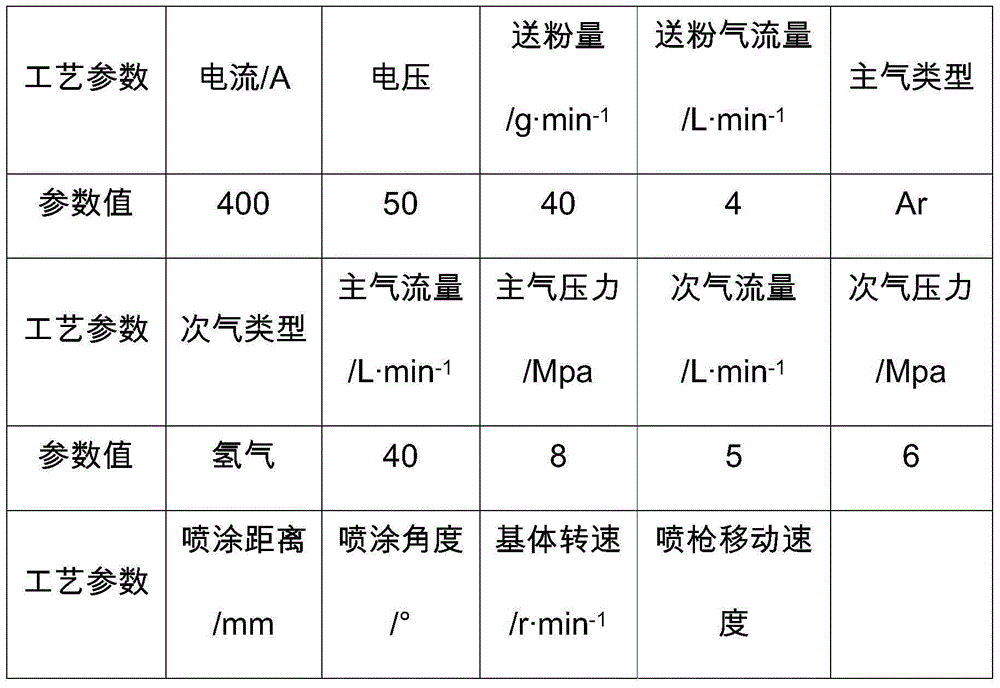

[0036] A 0.1mm nickel-chromium-aluminum-yttrium coating was sprayed by plasma spraying method, and the parameters are shown in Table 2.

[0037] Table 2 Plasma spraying nickel chromium aluminum yttrium primer parameters

[0038]

[0039]

[0040] The zirconia spraying powder is sprayed on the subs...

Embodiment 2

[0046] A zirconia target material with a thickness of 6 mm is sprayed on a stainless steel tube with an outer diameter of 165 mm and a length of 2791 mm.

[0047] After mechanically mixing zirconia powder with a mass percentage of 95 wt%, a purity of not less than 99.5 wt%, and a particle size of 3um and a mass percentage of carbon powder with a mass percentage of 5 wt%, it was sintered at 1600°C for 8 hours with hydrogen, and then the sintered The powder is spray-dried and granulated to obtain zirconia spray powder of 140-325 mesh.

[0048] Use absolute ethanol to remove oil stains on the surface, and sandblast to make the surface of the substrate reach a certain roughness.

[0049] The 0.3mm nickel-chromium coating was sprayed by plasma spraying method, and the parameters are shown in Table 4.

[0050] Table 4 Plasma Spraying Nickel-Chromium Primer Parameters

[0051]

[0052]

[0053] The zirconia spray powder is sprayed on the substrate tube that has been sprayed wit...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Particle size | aaaaa | aaaaa |

| Thickness | aaaaa | aaaaa |

| Thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com