Preparation method for hydroxylapatite coating

A hydroxyapatite and coating technology, applied in coating, metal material coating process, melt spraying and other directions, can solve the problems of large residual stress, decreased coating bonding strength, insufficient crystallinity, etc. Fine structure, reduced residual stress, controllable effect of coating porosity

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

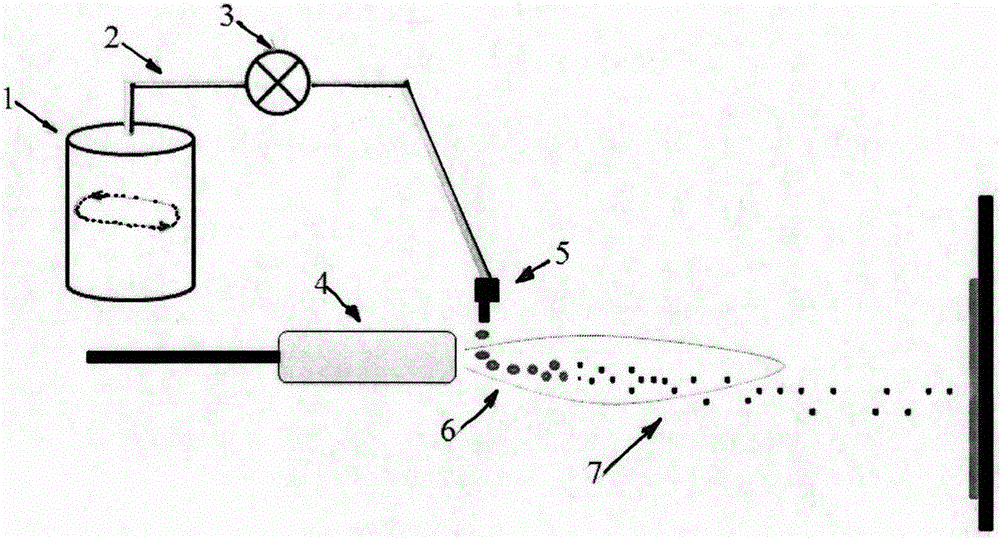

Method used

Image

Examples

Embodiment 1

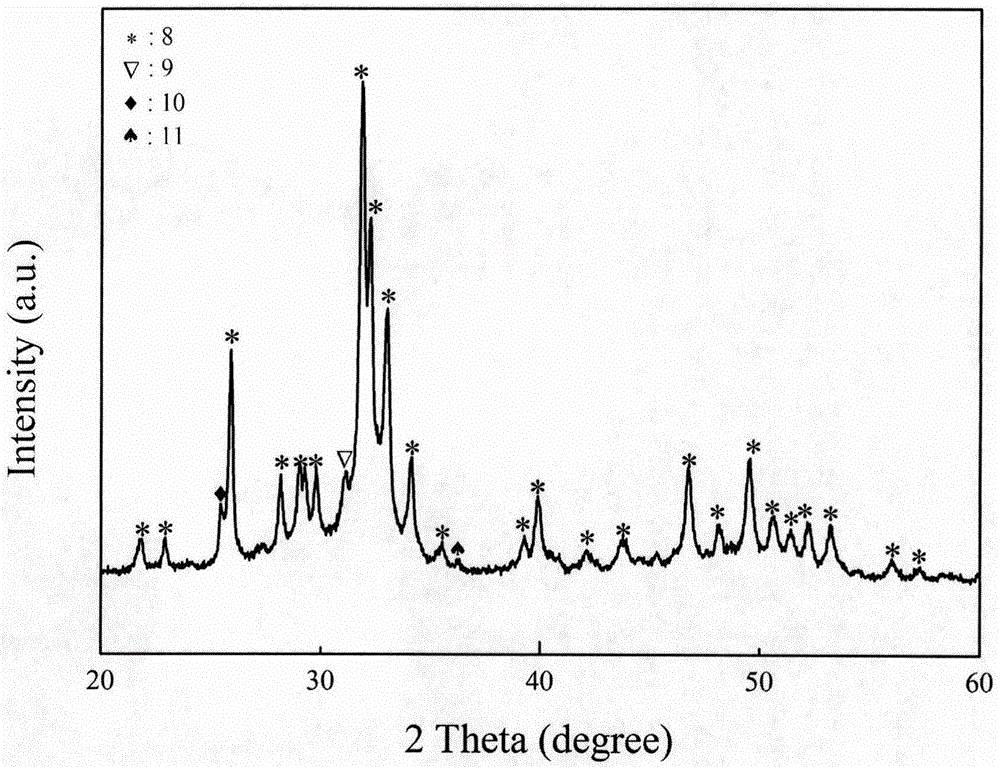

[0060] Disperse 35g of hydroxyapatite powder with a particle size of about 0.5μm in 500mL of absolute ethanol, add a small amount of polyethylene glycol, and form a stable suspension after magnetic stirring. The needle of mm is fed into the flame flow of the flame spray gun, and deposited on the 45 steel substrate to form the hydroxyapatite coating. The gas used by the spray gun is oxygen and acetylene, the moving speed of the spray gun is 150m / s, and each time it moves down 2mm, spraying 15 times continuously. The phase structure was observed by X-ray diffractometer, such as figure 2 As shown, through XRD phase calibration, hydroxyapatite 8, tricalcium phosphate 9, tetracalcium phosphate 10, calcium oxide 11, hydroxyapatite 8 have the strongest peak and the highest content, and the crystallinity of the coating is calculated to be 75%.

Embodiment 2

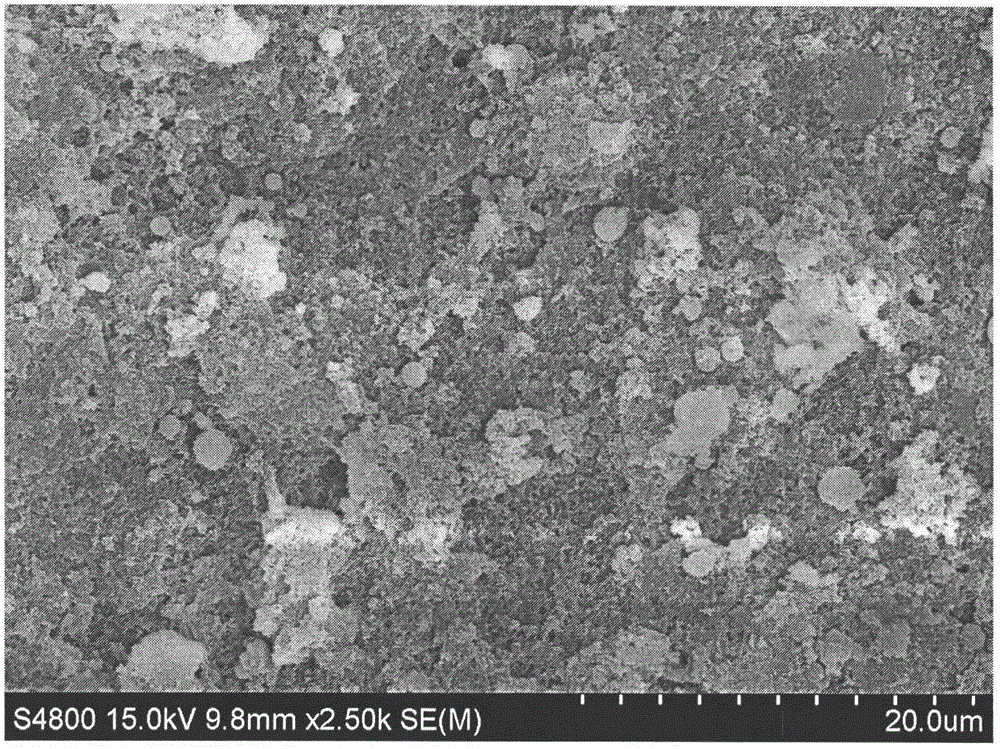

[0062] Disperse 50g of hydroxyapatite powder with a particle size of about 1 μm in 1000mL of deionized water, add a small amount of dispersant, form a stable suspension after magnetic stirring, and pass the suspension at a flow rate of 25mL / min. The needle is fed into the plume of the plasma torch, and the hydroxyapatite coating is deposited on the titanium alloy substrate. During the spraying process, the spraying power is 30kW, the moving speed of the spray gun is 200m / s, and each time moves down 2mm, spraying continuously for 20 times. The surface microstructure of the coating was observed with a field emission scanning electron microscope. Such as image 3 As shown, there is a low porosity, no large pores, and the coating is well bonded. The coating thickness is 240 μm, that is, the coating deposition rate is about 12 μm / time. Calculated by XRD spectrum, the crystallinity of the coating is 68%. This parameter is suitable for preparing hydroxyapatite coatings with thinne...

Embodiment 3

[0064] The precursors of 0.5M calcium nitrate, 0.3M diammonium hydrogen phosphate and 0.4M ammonia solution are sent into the flame flow of the plasma spray gun through a needle with an inner diameter of 0.22mm at a flow rate of 30mL / min, and deposited on the stainless steel substrate to form hydroxyapatite stone coating. During the spraying process, the spray gun moves at a speed of 250m / s, moves down 3mm each time, and sprays continuously for 20 times. The microstructure was observed with a field emission scanning electron microscope (FE-SEM). Such as Figure 4 As shown, there are small pores locally, and the porosity is moderate. Through section analysis, the thickness of the coating is 240 μm, that is, the deposition rate of the coating is about 12 μm / time, and the crystallinity of the coating is 70% calculated by the XRD pattern. This parameter is suitable for the preparation of hydroxyapatite coatings with thinner thickness and porous structure.

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle diameter | aaaaa | aaaaa |

| particle diameter | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com