Method for preparing two-dimensional periodic metal particle array structure through dual-wavelength femtosecond lasers

A femtosecond laser, two-dimensional period technology, applied in laser welding equipment, metal processing equipment, welding equipment and other directions, can solve the problems of complex optical path design and working device, and the influence of two-dimensional structure space period, so as to achieve low cost and high efficiency High and operability effects

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

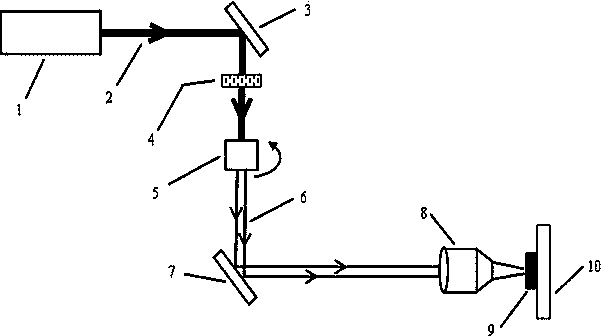

[0051] Such as figure 1 As shown in the optical path structure, after the femtosecond laser 2 generated by the femtosecond laser 1 is incident on the total reflection mirror 3, its reflected light is irradiated vertically to the surface of the BBO frequency doubling crystal 5 through the neutral attenuator 4, and then the dual-wavelength femtosecond laser generated 6 passes through the dichroic mirror 7 and enters the focusing element 8, and the focused two-color femtosecond laser irradiates the surface of the metal target sample 9 fixed on the three-dimensional precision mobile platform 10 to induce the formation of a two-dimensional periodic distribution of submicron particle arrays structure.

[0052] Among them, the laser pulse output from the femtosecond laser has the following characteristic parameters: a repetition frequency of 1000 Hz, a pulse width of 50 femtoseconds, a center wavelength of 800 nanometers, and horizontal linear polarization. After passing through the...

Embodiment 2

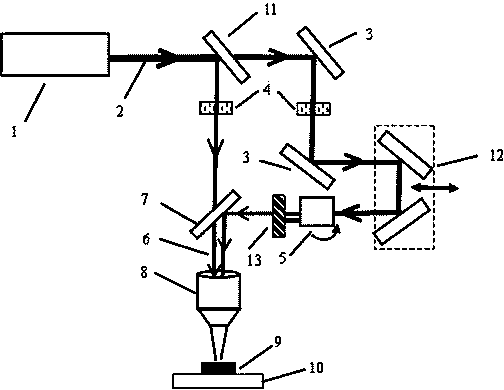

[0054] Such as figure 2 As shown in the optical path structure, the femtosecond laser 2 generated by the femtosecond laser 1 passes through the beam splitter 11 to form two laser pulses, and then enters two different optical paths respectively, and the femtosecond laser in the optical path of one arm is only neutrally attenuated Sheet 4 reaches the dichroic mirror 7, and the femtosecond laser in the other arm of the optical path enters the adjustable time delay line 12 after passing through the total reflection mirror 3 and the neutral attenuation sheet 4, and then vertically irradiates the BBO frequency doubling crystal after a time delay 5, and then reach the dichroic mirror 7 through the optical filter 13, and the two laser beams are respectively transmitted and reflected by the dichroic mirror 7 to become a collinearly transmitted dual-wavelength femtosecond laser pulse, which is focused by the optical element 8 The surface of the metal target sample 9 fixed on the three-...

Embodiment 3

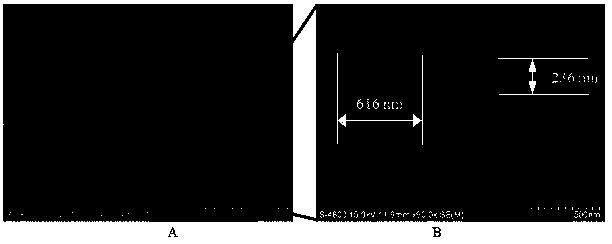

[0057] On the basis of the optical path in Example 1, a neutral attenuator is used to attenuate the fundamental frequency femtosecond laser power incident on the BBO crystal, and the azimuth angle of the BBO crystal is rotated to obtain the maximum frequency doubling efficiency, that is, the crystal o The axis is parallel to the polarization direction of the incident fundamental-frequency laser, so that the remaining 800-nm laser output afterwards maintains the original linear polarization, while the 400-nm frequency-doubled laser is also linearly polarized, and the polarization directions of the two are perpendicular to each other. The total power of the dual-wavelength femtosecond laser after reflection by the dichroic mirror is 2 milliwatts, and the sample surface is placed at a position 400 microns in front of the laser focus. image 3Shown are scanning electron micrographs of the processing effect obtained when the sample scanning speed is 0.04 mm / s, and the magnifications...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com