Method for improving infrared band transmittance by processing micro-nano structure on surface of chalcogenide glass

A chalcogenide glass, micro-nano structure technology, applied in optical components, optics, instruments, etc., can solve the problems of unsuitable scale three-dimensional structure, only suitable for, unable to control the microstructure morphology, etc., to solve the problem of film quality, The effect of avoiding contact damage and good anti-reflection micro-nano structure stability

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

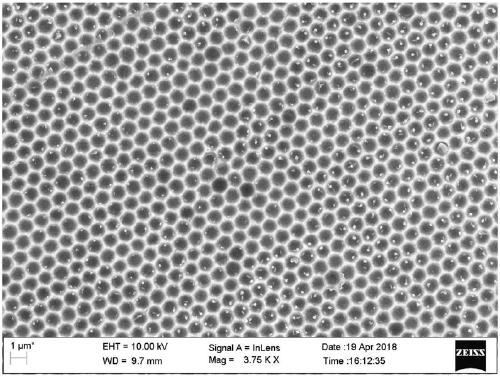

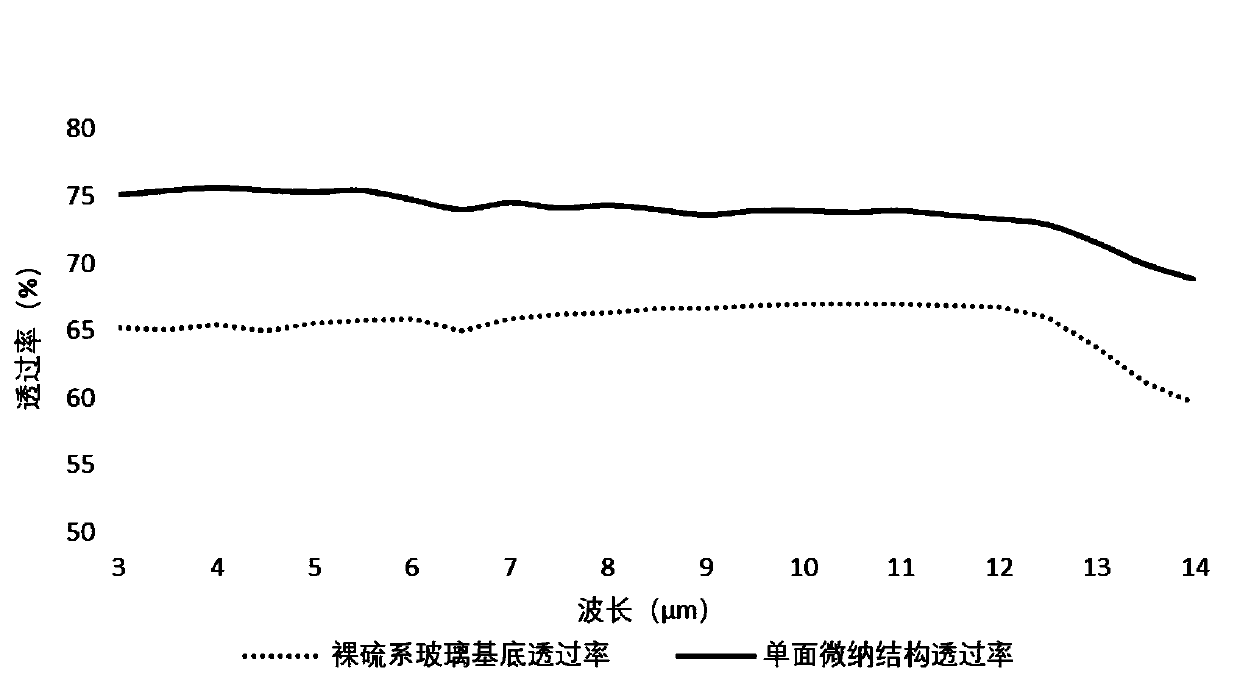

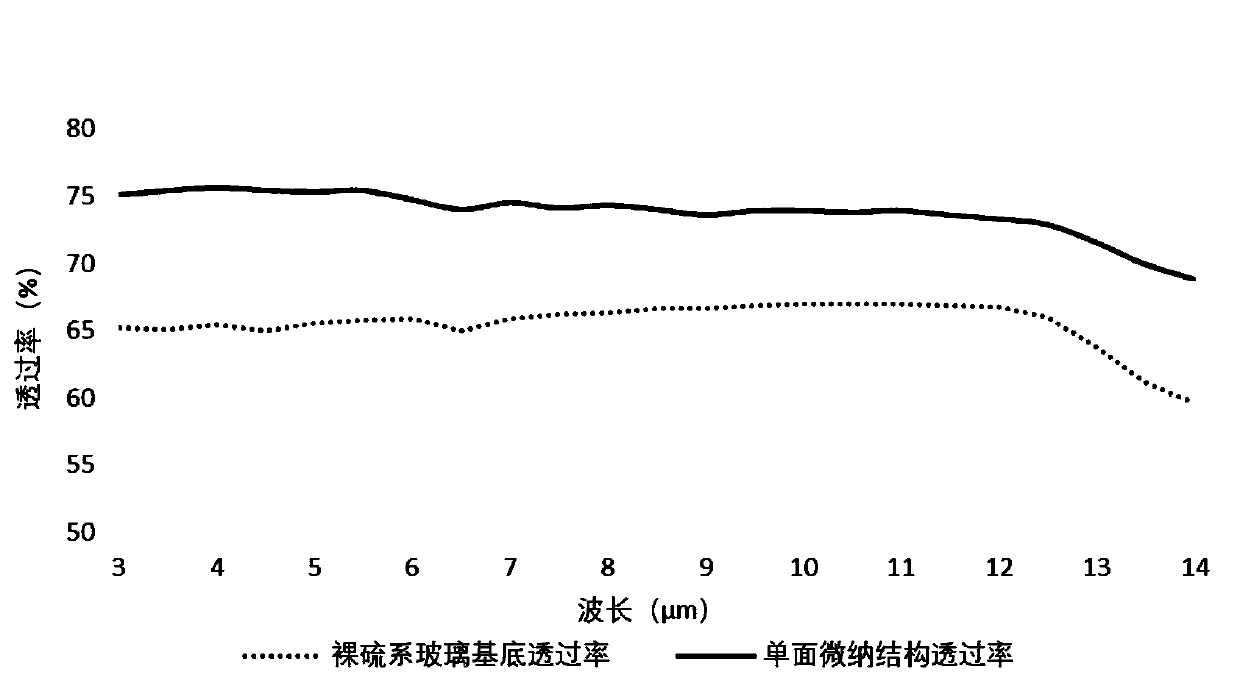

[0027] For the chalcogenide glass As40Se60 (As40Se60, Joint Research Center of Chengdu University of Information Technology & Chengdu Lansun Optoelectronics Technology Co., Ltd.), a regularly arranged three-dimensional bowl-shaped micro-nano structure is designed to achieve 3 μm ~ 12 μm broadband anti-reflection, specifically The processing process is as follows:

[0028] (1) On the surface of the chalcogenide glass As40Se60, apply a coating of ultraviolet imprinting glue (code name 04n, Obducat micro-nano imprinting company) with a thickness of 100nm in a glue-spinning manner;

[0029] (2) Use the SiC printing plate engraved with the target pattern (arranged by three-dimensional bowl-shaped structural units, consistent with the micro-nano structure etched on the surface of the chalcogenide glass As40Se60) to imprint the polyethylene (PE) transfer template, first in Heat at 155°C for 100s, then cool down to 100°C and hold for 90s, then cool down to 90°C, transfer the target pa...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com