Micro-nano machining method based on electrochemical micro-nano system for functional material and device thereof

A functional material, micro-nano processing technology, applied in microstructure devices, manufacturing microstructure devices, metal material coating processes, etc., can solve problems such as poor mechanical strength and low contact resistance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

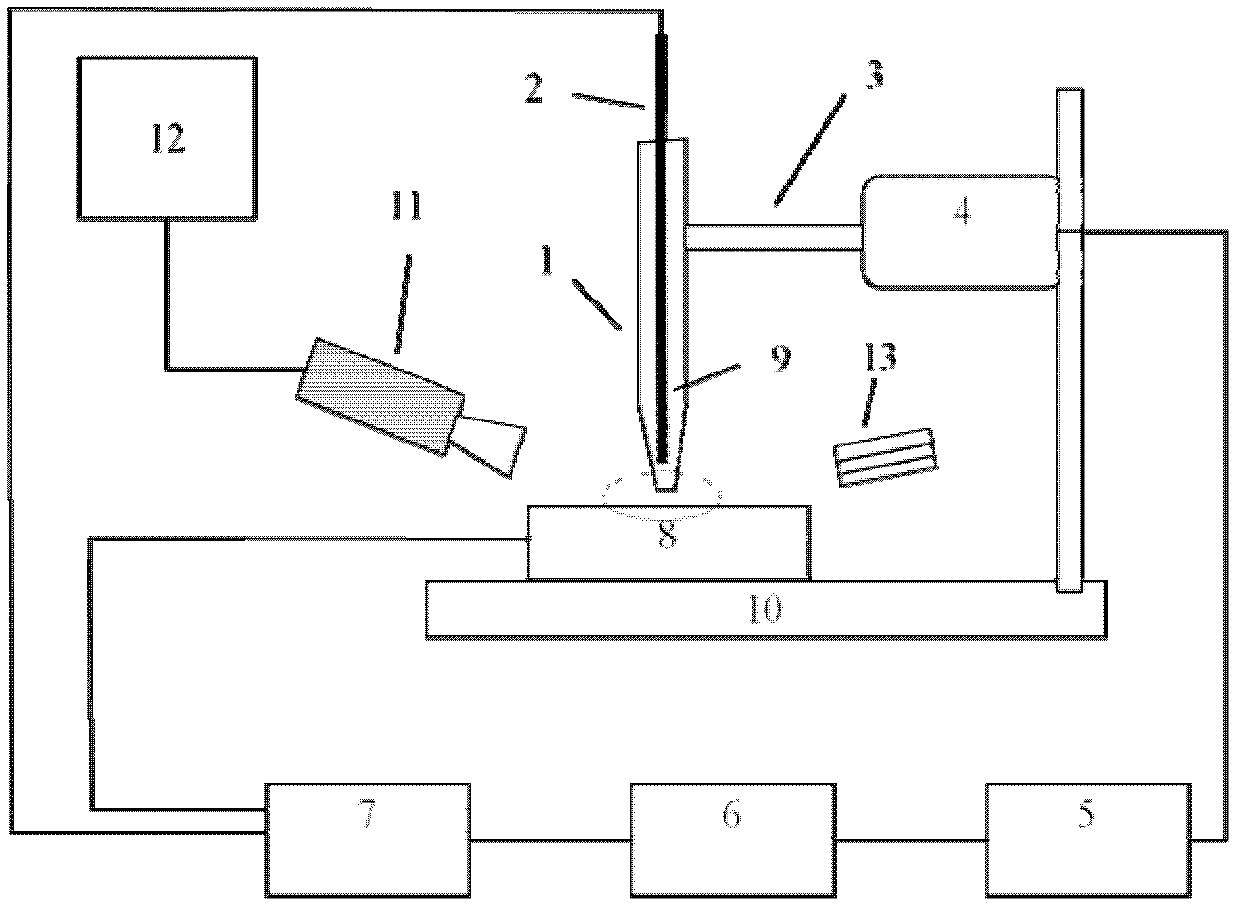

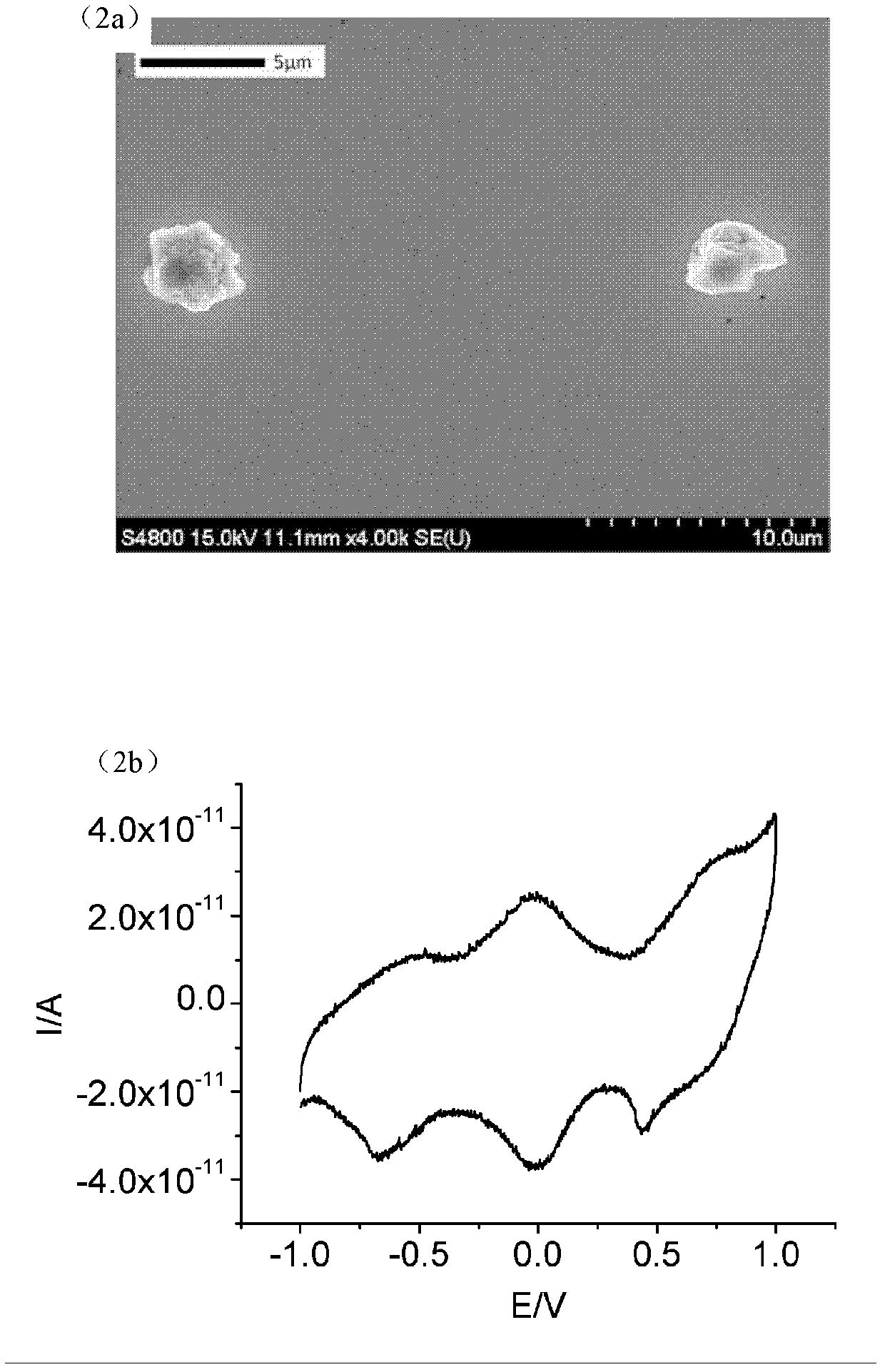

[0062] This example uses figure 1 The processing apparatus shown was carried out. Processing conditions: use a glass capillary with a tip opening diameter of 5 microns as the container of the electrochemical reactor, and the solution in the capillary contains 0.001mol / dm 3 Silicotungstic acid (H 4 SiW 12 o 40 ), the solvent is water; in an indoor environment; the Ag wire with a diameter of 0.3mm is used as a reference electrode and a counter electrode, and a platinum-plated glass sheet is used as a working electrode. Start the three-dimensional micro-motion system, and according to the screen observation of the video monitoring system, move the glass capillary so that the tip of the glass capillary gradually approaches the platinum surface until the solution at the tip of the capillary just contacts it. Start the electrochemical workstation, adopt cyclic voltammetry, and the parameters of cyclic voltammetry are as follows: scan rate 0.1V / s, highest potential 0.2V, lowest p...

Embodiment 2

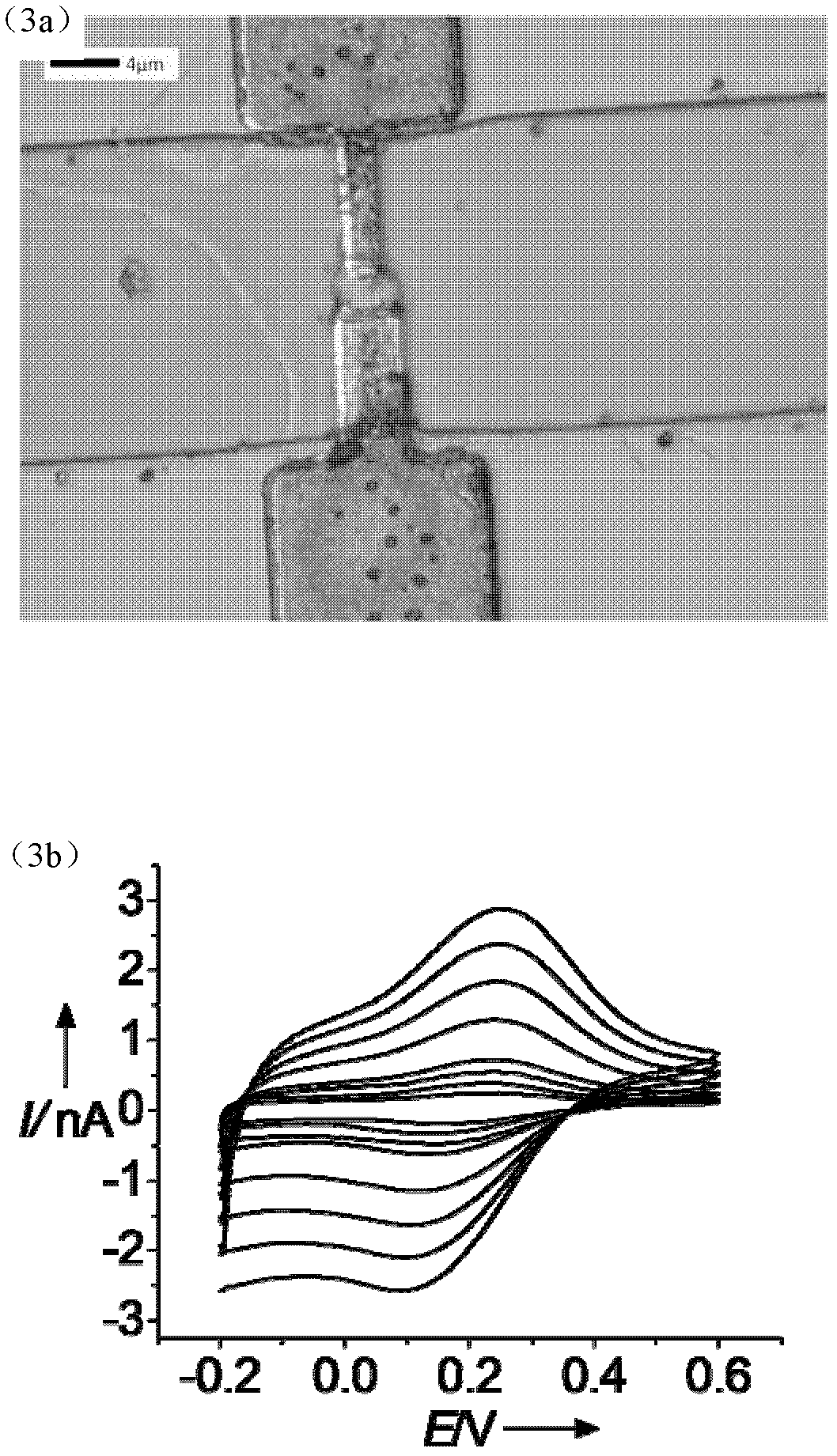

[0064] This example uses figure 1 The processing apparatus shown was carried out. In this embodiment, sodium chloride crystals doped with potassium ferrocyanide, potassium ferricyanide and Prussian blue are synthesized on a microchip. Processing conditions: the microchip is cleaned after soaking in acetone for 12 hours; the container used has a tip diameter of 5 Micron glass capillary, the solution in the capillary contains 0.05mol / dm 3 Sodium chloride (NaCl), 0.001mol / dm 3 Potassium ferrocyanide (K 4 Fe(CN) 6 ), the solvent is water; in an indoor environment; the Ag wire with a diameter of 0.3mm is used as a reference electrode and a counter electrode, and the cleaned microchip is used as a working electrode. Start the three-dimensional micro-motion system, and according to the screen observation of the video monitoring system, move the glass capillary so that the tip of the glass capillary gradually approaches the characteristic position of the microchip until the soluti...

Embodiment 3

[0067] This example uses figure 1 The processing apparatus shown was carried out. In this embodiment, sodium chloride crystals doped with potassium ferrocyanide, potassium ferricyanide and Prussian blue are synthesized on a platinum-plated glass sheet. The processing conditions are as follows: a glass capillary with a diameter of 5 microns at the tip of the opening is used as the container, The solution in the capillary contains 0.05mol / dm 3 Sodium chloride (NaCl), 0.00001mol / dm 3 Potassium ferrocyanide (K 4 Fe(CN) 6 ), the solvent is water; in an indoor environment; the Ag wire with a diameter of 0.3mm is used as a reference electrode and a counter electrode, and a platinum-plated glass sheet is used as a working electrode. Start the three-dimensional micro-motion system, and according to the screen observation of the video monitoring system, move the glass capillary so that the tip of the glass capillary gradually approaches the surface of the platinum-coated glass slide...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com