Sub- and micro- Newton level force measuring system

A measurement system, a micro-newton technology, is applied to the components of the TV system, the measurement of the property force of the piezoelectric device, and the TV, etc., to achieve the effect of small range, high sensitivity and reliable method.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

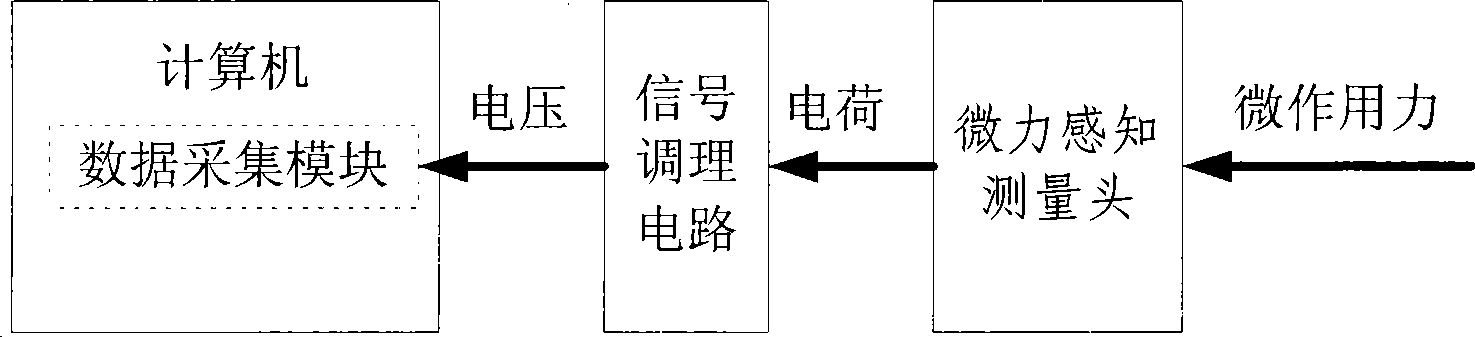

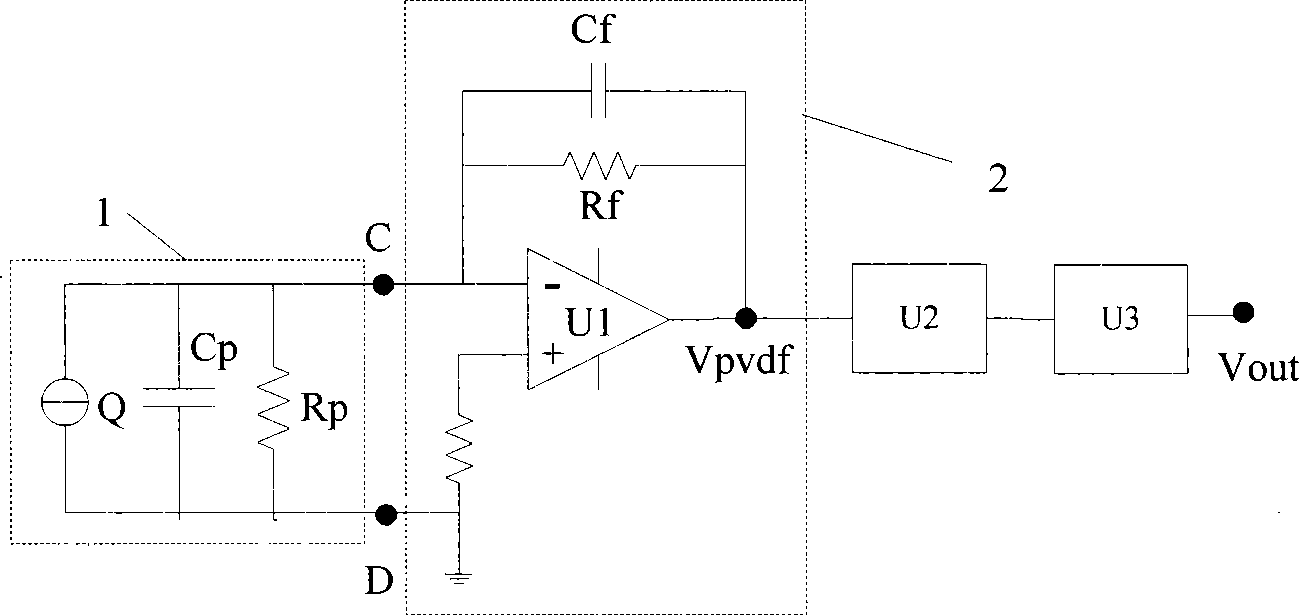

[0021] The sub-micro-Newton force measurement system of the present invention is composed of a micro-force sensing measuring head, a signal conditioning circuit (Conditioning Circuit) and a data acquisition module installed in a computer, wherein the micro-force sensing measuring head receives the micro-action force from the probe and converts the force signal into The charge is then sent to the signal conditioning circuit, which converts it into a suitable voltage that can be detected. The data acquisition module converts the obtained voltage signal through A / D conversion, and uses the relationship between the calibrated micro force and the output voltage of the signal conditioning circuit to convert the voltage value into the micro force value received during operation.

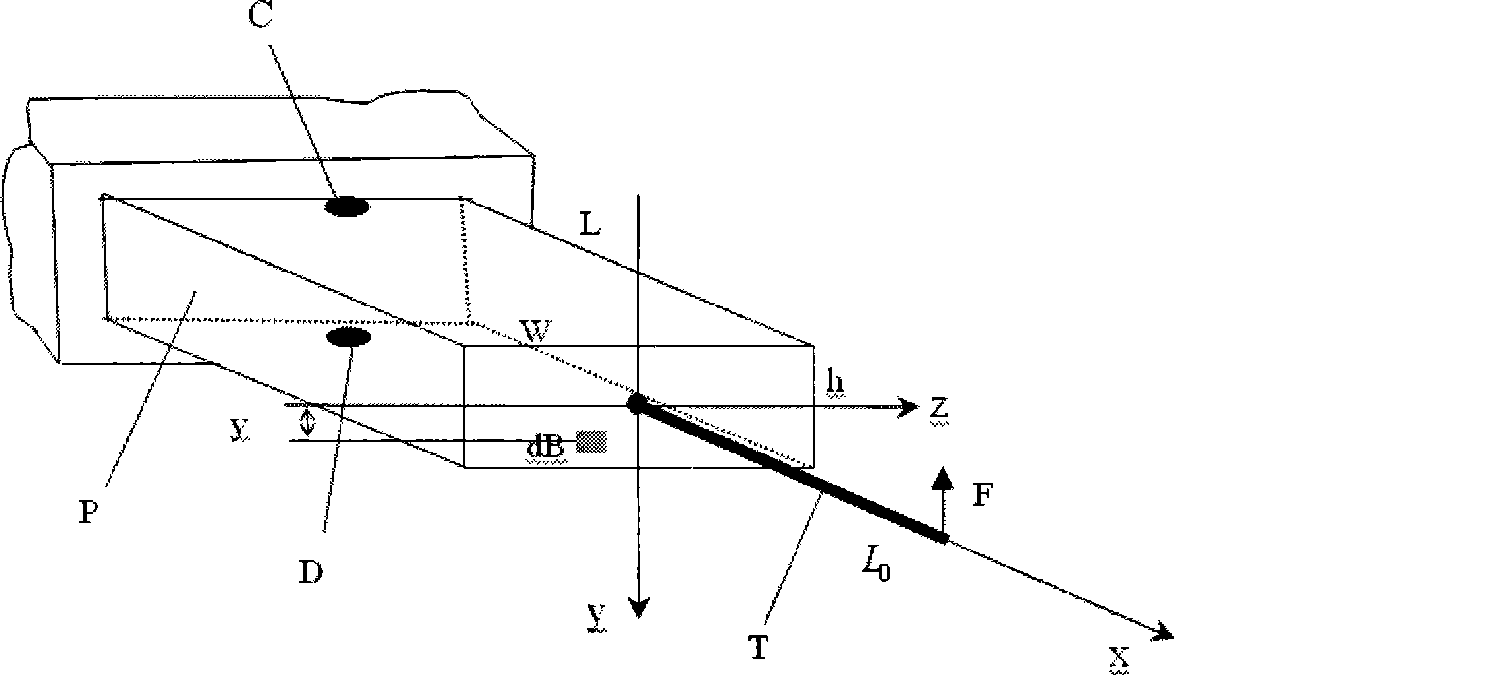

[0022] 1. The micro-force sensing measuring head adopts a micro-force sensing measuring head based on PVDF piezoelectric material, and this micro-force sensing measuring head adopts a simple and practical ca...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com