Super-resolution laser printing device based on columnar vector polarized light

A vector polarization and laser printing technology, which is applied in the field of super-resolution laser printing devices, can solve the problem of long wavelength excitation of two-photon absorption effect, two-photon laser printing technology cannot reach the resolution of projection micro-nano processing technology, and it is difficult to break through sub-hundred nanometers Resolution and other issues, to achieve the effect of small half-height full-width

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

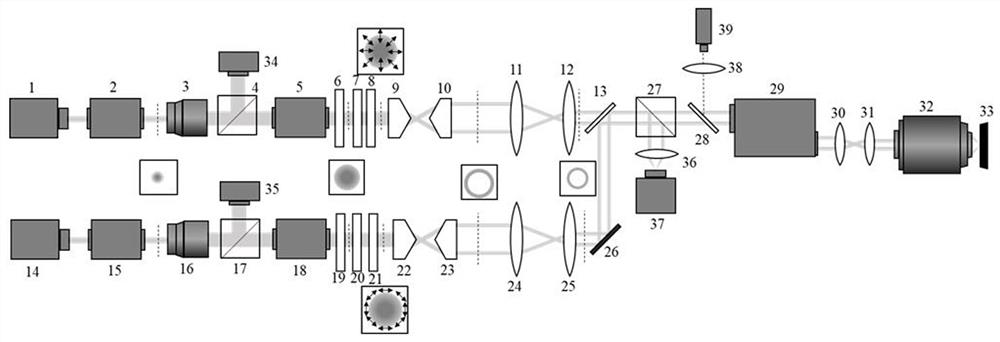

[0021] The present invention will be further described below in conjunction with accompanying drawing.

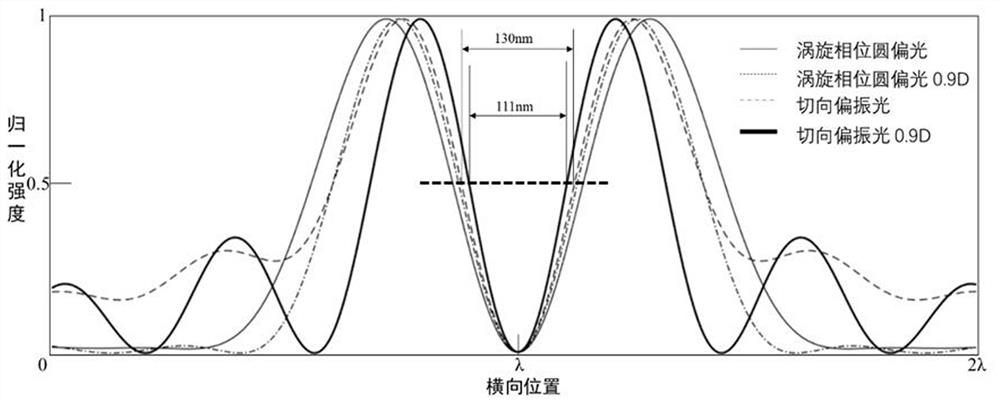

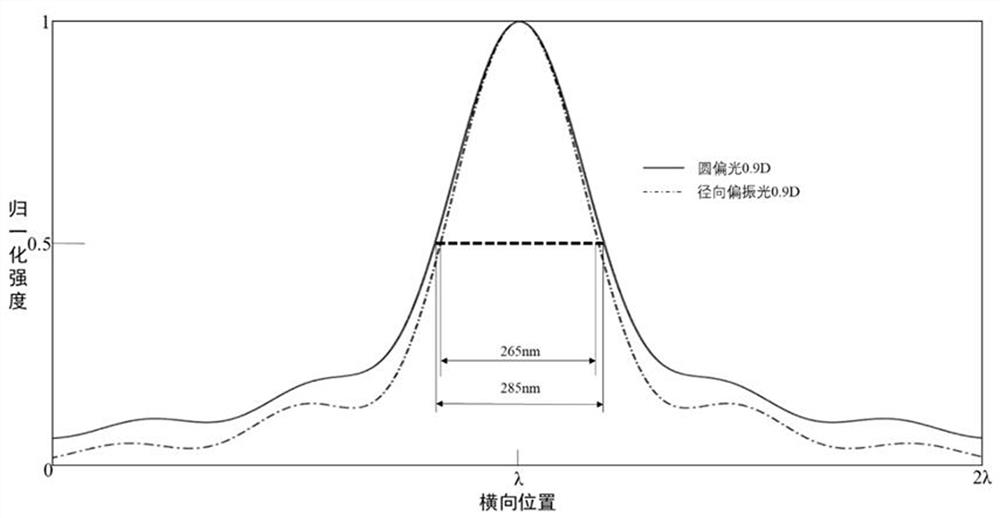

[0022] Such as figure 1 As shown, in the present invention, the hollow spot produced by focusing the tangentially polarized beam is compared with the hollow spot produced by the focusing of the vortex phase circularly polarized light. D is the diameter of the entrance pupil, ensuring that the beam fills the entrance pupil, that is, making full use of the numerical aperture of the objective lens. The numerical aperture adopted in this example is 1.45, and the wavelength of the suppressed beam is 532 nm. The thin solid line in the figure is the hollow spot formed by the vortex phase circularly polarized light, the dotted line is the hollow spot formed by the tangentially polarized light, the dotted line is the hollow spot formed by the focusing of the annular vortex phase circularly polarized light with an inner diameter of 0.9D, and the thick solid line The lines are hollow...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com