Portable low-resistance two-phase flow water mist fire extinguishing system

A fire extinguishing system and low-resistance technology, applied in the field of fire-fighting and two-phase flow gas water mist fire extinguishers, can solve the problems of high air pressure and heavy equipment, and achieve the effects of simple equipment, small energy loss, and reduced pipelines

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

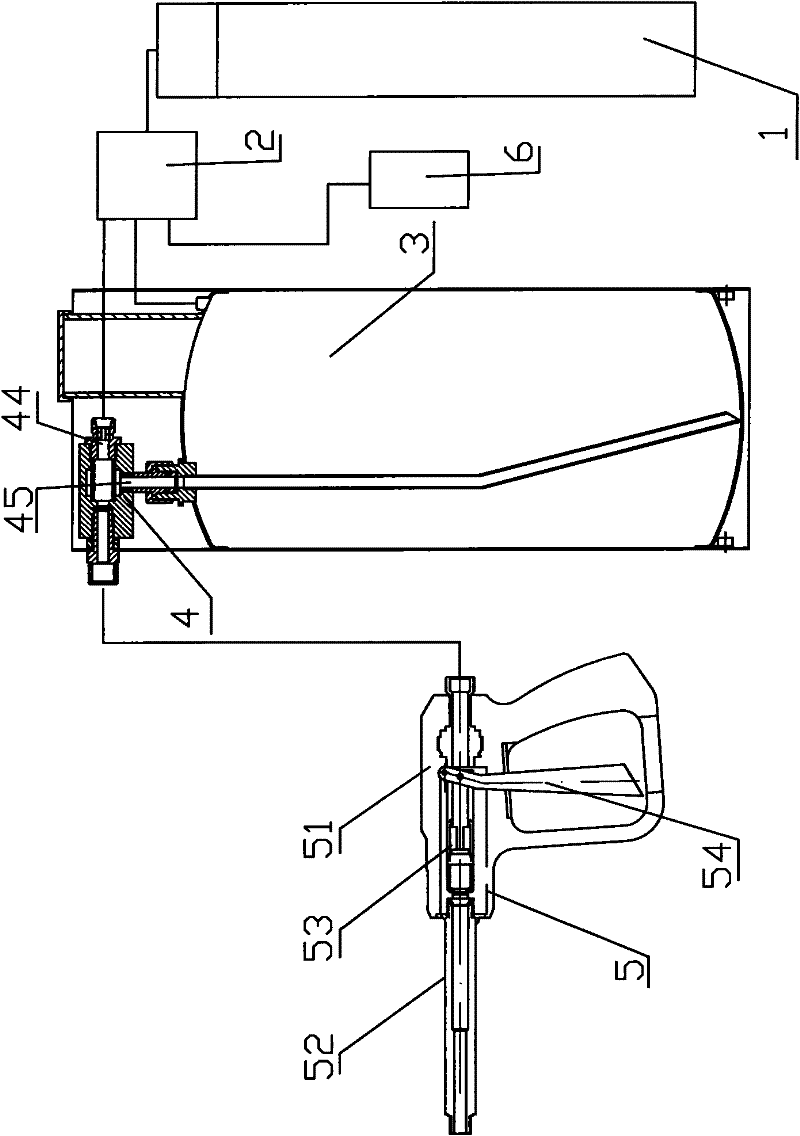

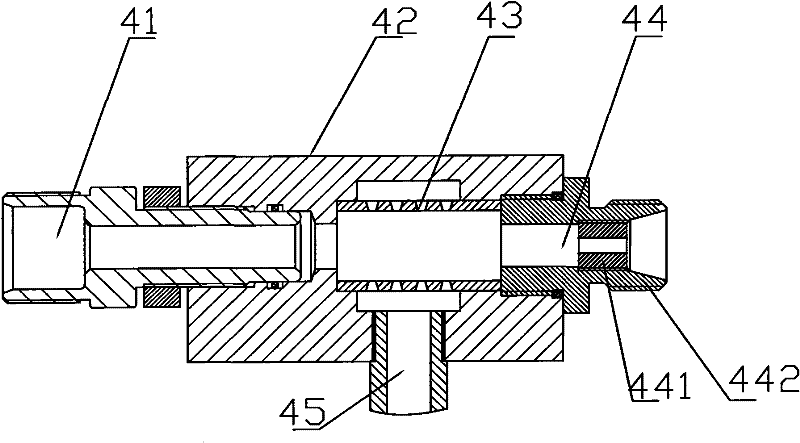

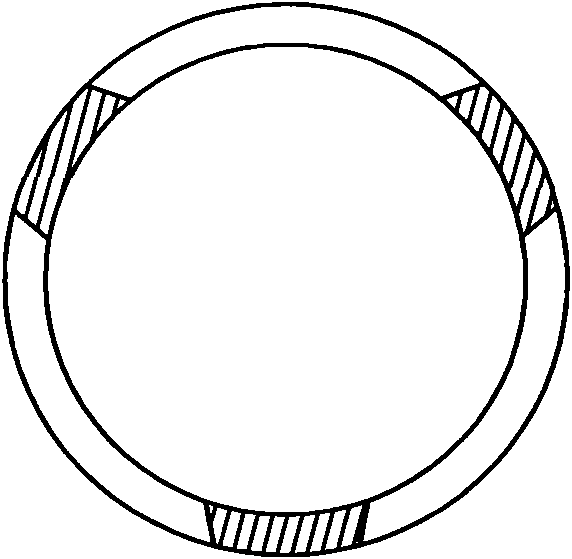

[0045] figure 1 Shown is a portable low-resistance two-phase flow water mist fire extinguishing device, including a high-pressure gas cylinder 1, a pressure reducing valve 2, a water storage bottle 3, an air-water mixer 4, a spray gun 5 and an air breathing apparatus mask 6. The high-pressure gas cylinder 1 is connected to the pressure reducing valve 2 through a pipeline, and the output of the pressure reducing valve is connected to the intake pipe 44 of the gas-water mixer 4 one way, one way is connected to the water storage bottle 3, and the other way is connected to the air respirator through a pipeline mask6. The water outlet of the water storage bottle communicates with the water inlet pipe 45 of the air-water mixer 4 , and is connected with the spray gun 5 through the pipeline after being mixed by the air-water mixer 4 . The air-water mixer 4 is placed above the water storage bottle 3, and the spray gun 5 includes a housing 51, a trigger valve 53 placed in the housing,...

Embodiment 2

[0054] Portable low-resistance two-phase flow fine water mist fire extinguishing system with lower outlet structure such as Figure 6 As shown, the gas-water mixer 4 is placed under the water storage bottle 3. When using the fire extinguisher to work, the trigger 54 of the spray gun is pulled, and the trigger valve 53 is opened. In the valve 2, the high-pressure gas is decompressed by the pressure reducing valve 2 and divided into three paths, one path directly enters the gas-water mixer 4 through the pipeline, one path enters the water storage bottle 3 through the pipeline, and the other path is connected to the air respirator through the pipeline mask6. The water in the water storage bottle 3 is pressed into the air-water mixer 4 by the high-pressure gas; after passing through the air-water mixer, it enters the spray gun 5 through a hose and sprays out. The portable low-resistance two-phase flow fine water mist fire extinguishing system with the lower water outlet structure...

Embodiment 3

[0056] Portable low-resistance two-phase flow water mist fire extinguishing system with dual cylinders such as Figure 7 Shown, this system comprises a high-pressure cylinder 1 and an air respirator cylinder 1' that can be used by the respirator. After the two gas cylinders are connected by the pipeline, the output high-pressure gas is decompressed by the pressure reducing valve 2 and then divided into three paths, one path directly enters the gas-water mixer 4 through the pipeline, one path enters the water storage bottle 3 through the pipeline, and the other Connect the air respirator face mask 6 by pipeline. The water in the water storage bottle 3 is pressed into the air-water mixer 4 by the high-pressure gas; after passing through the air-water mixer, it enters the spray gun 5 through a hose and sprays out.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com