Refrigeration equipment and compressors

A compressor and pressure control technology, applied in mechanical equipment, machines/engines, liquid fuel engines, etc., can solve problems affecting performance and reliability, external heat exchanger vibration effects, rising costs, etc., to achieve balanced pressure difference, Improve the installation method and retain the effect of energy

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

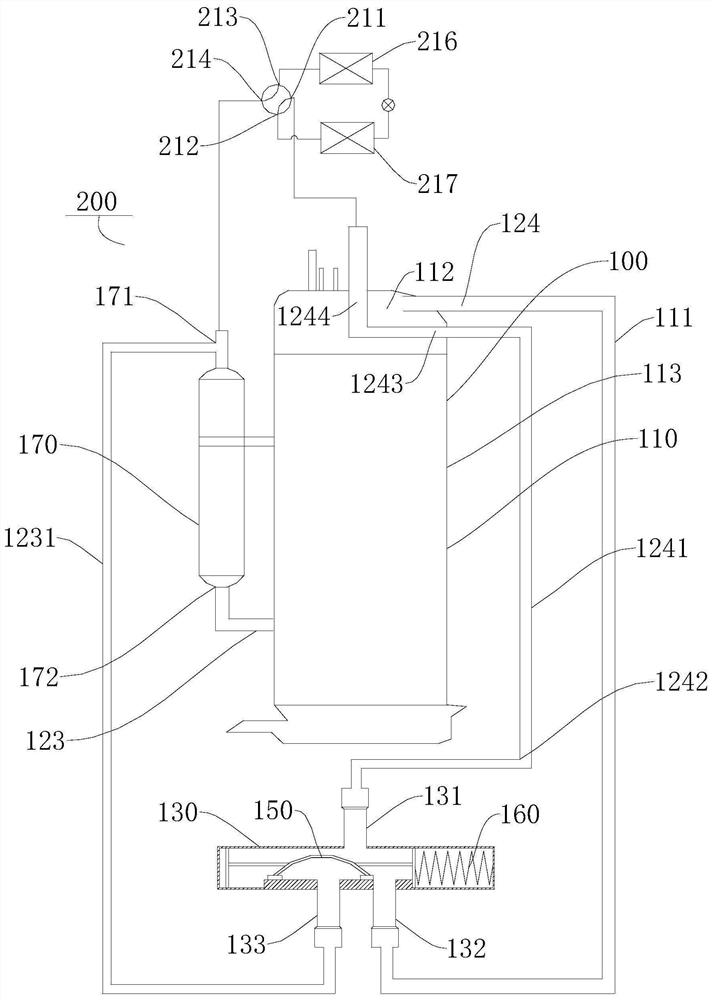

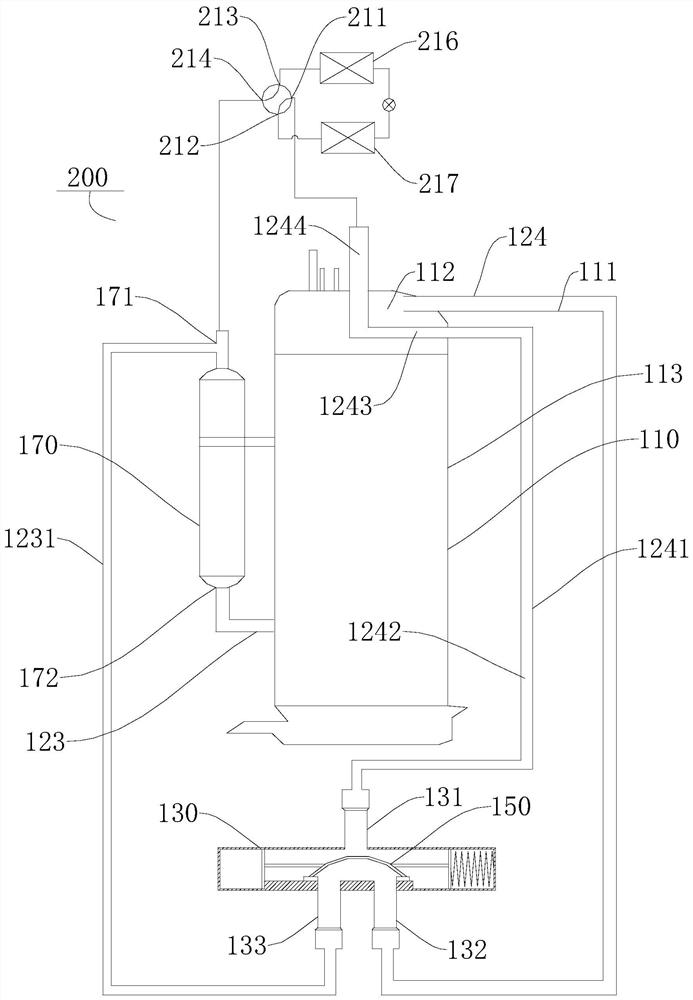

[0041] The compressor 100 and the refrigeration equipment 200 according to the embodiment of the present invention are described below with reference to FIGS. 1-3.

[0042] As shown in FIG. 1 and FIG. 2, the compressor 100 according to an embodiment of the present invention includes a casing 110, a compression mechanism 120, a suction

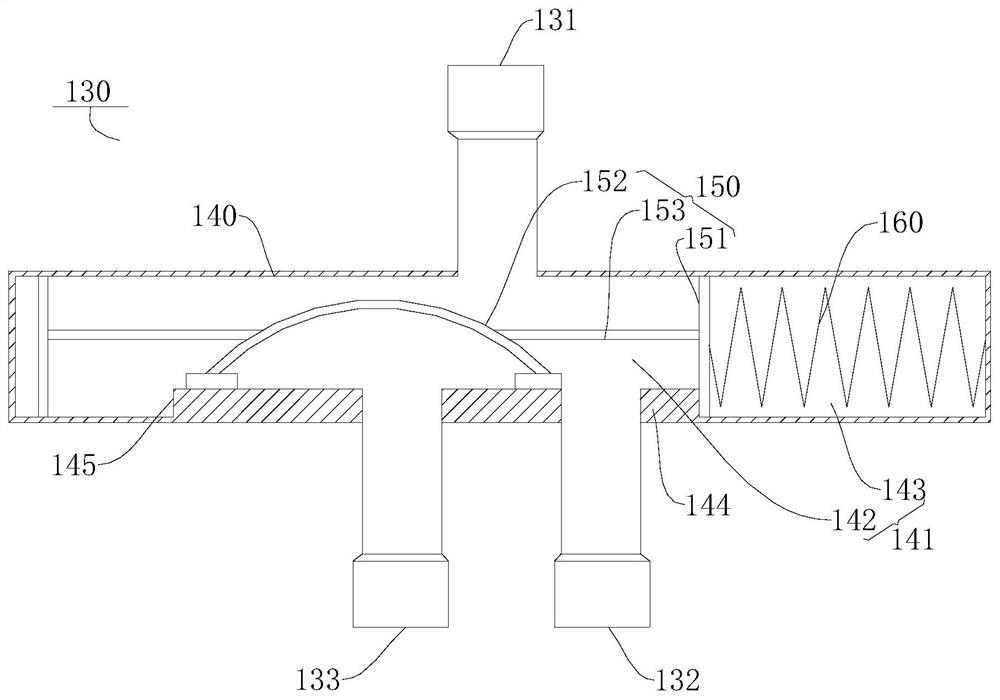

[0045] When the compressor 100 is in the refrigeration state, the third valve port 133 communicates with the suction pipe 123 through the first pipeline 1231,

[0046] When the compressor 100 stops running, in the pressure control valve 130, the third valve port 133 communicates with the second valve port 132,

[0047] According to the compressor 100 of the embodiment of the present invention, by setting the pressure control valve 130, and making the second pipeline 1241 pass through

[0048] According to some embodiments of the present invention, the second pipeline 1241 includes a first section 1242, a first section 1242, a

[0049] It can be unde...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com