A spindle sealing method for a working motor under high temperature or high pressure environment

A high-voltage environment, working motor technology, applied in the direction of engine sealing, electromechanical devices, electrical components, etc., can solve the problems of easy damage to the seal, the motor cannot work normally and stably, and the motor is damaged.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

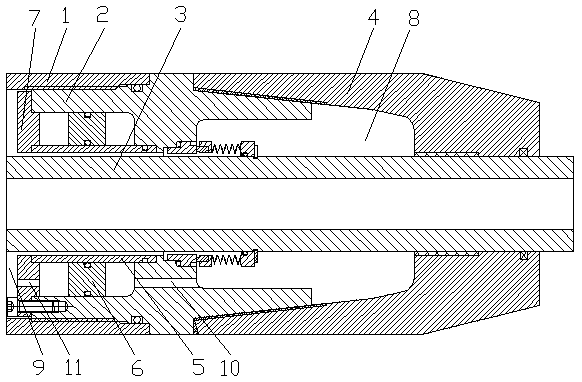

[0044] see figure 1 , a method for sealing a main shaft of a motor working in a high-temperature or high-pressure environment, comprising a packaging step, including a piston assembling step and a sealing step before the packaging step;

[0045] The piston assembling step refers to first assembling the piston rod 5 and the piston 6 between the motor housing 1 and the main shaft 3, and packaging the piston end cover 7;

[0046] The sealing step refers to assembling a first seal on the first joint 2, and assembling a second seal between the second joint 4 and the main shaft;

[0047] The packaging step refers to connecting the first joint 2 to the motor housing 1, the second joint 4 to the first joint 2, the first joint 2, the second joint 4 and the main shaft 3 to form a transition cavity 8, the motor housing 1, the main shaft 3 and the piston end cover 7 form an inner cavity 9, a first pressure balance hole 10 is set on the first joint 2, a second pressure balance hole 11 is ...

Embodiment 2

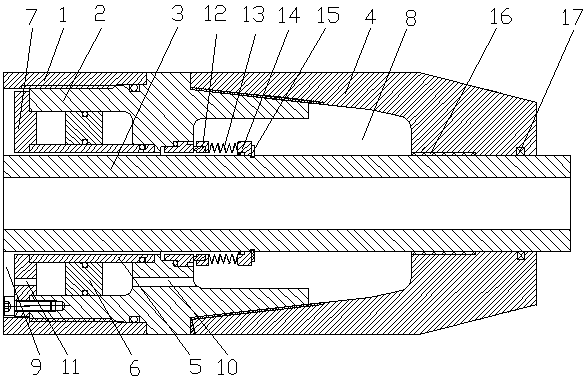

[0050] see figure 2 , a method for sealing a main shaft of a motor working in a high-temperature or high-pressure environment, comprising a packaging step, including a piston assembling step and a sealing step before the packaging step;

[0051] The piston assembling step refers to first assembling the piston rod 5 and the piston 6 between the motor housing 1 and the main shaft 3, and packaging the piston end cover 7;

[0052] The sealing step refers to assembling a first seal on the first joint 2, and assembling a second seal between the second joint 4 and the main shaft;

[0053] The packaging step refers to connecting the first joint 2 to the motor housing 1, the second joint 4 to the first joint 2, the first joint 2, the second joint 4 and the main shaft 3 to form a transition cavity 8, the motor housing 1, the main shaft 3 and the piston end cover 7 form an inner cavity 9, a first pressure balance hole 10 is set on the first joint 2, a second pressure balance hole 11 is...

Embodiment 3

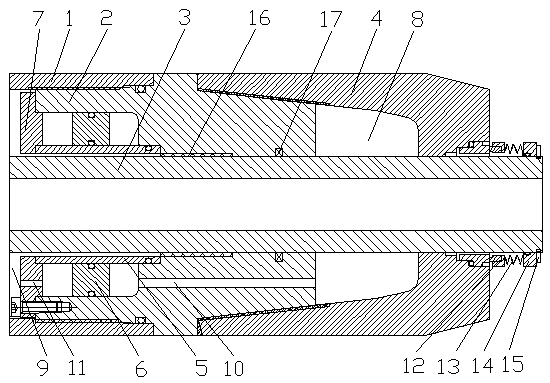

[0057] see image 3 , a method for sealing a main shaft of a motor working in a high-temperature or high-pressure environment, comprising a packaging step, including a piston assembling step and a sealing step before the packaging step;

[0058] The piston assembling step refers to first assembling the piston rod 5 and the piston 6 between the motor housing 1 and the main shaft 3, and packaging the piston end cover 7;

[0059] The sealing step refers to assembling a first seal on the first joint 2, and assembling a second seal between the second joint 4 and the main shaft;

[0060] The packaging step refers to connecting the first joint 2 to the motor housing 1, the second joint 4 to the first joint 2, the first joint 2, the second joint 4 and the main shaft 3 to form a transition cavity 8, the motor housing 1, the main shaft 3 and the piston end cover 7 form an inner cavity 9, a first pressure balance hole 10 is set on the first joint 2, a second pressure balance hole 11 is ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com