Hub motor stator support with low water resistance cooling structure and hub motor

A stator support, in-wheel motor technology, applied in cooling/ventilation devices, magnetic circuit shape/style/structure, electromechanical devices, etc., can solve problems such as large water resistance, and achieve low water resistance and good water cooling effect.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

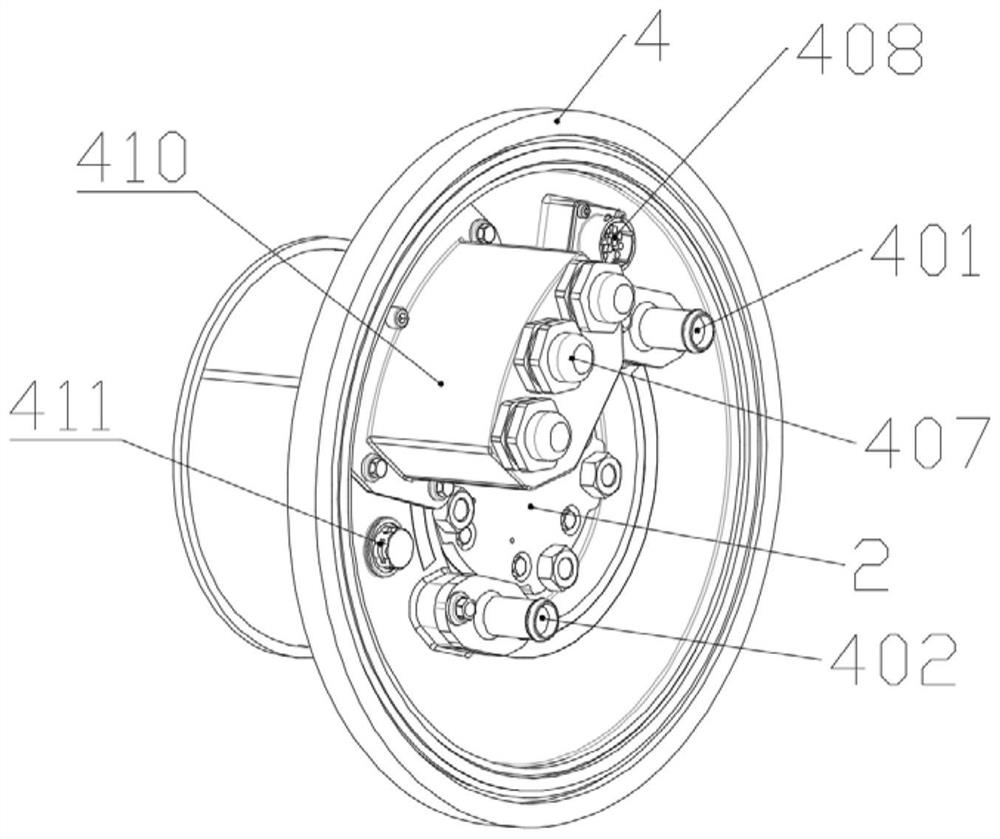

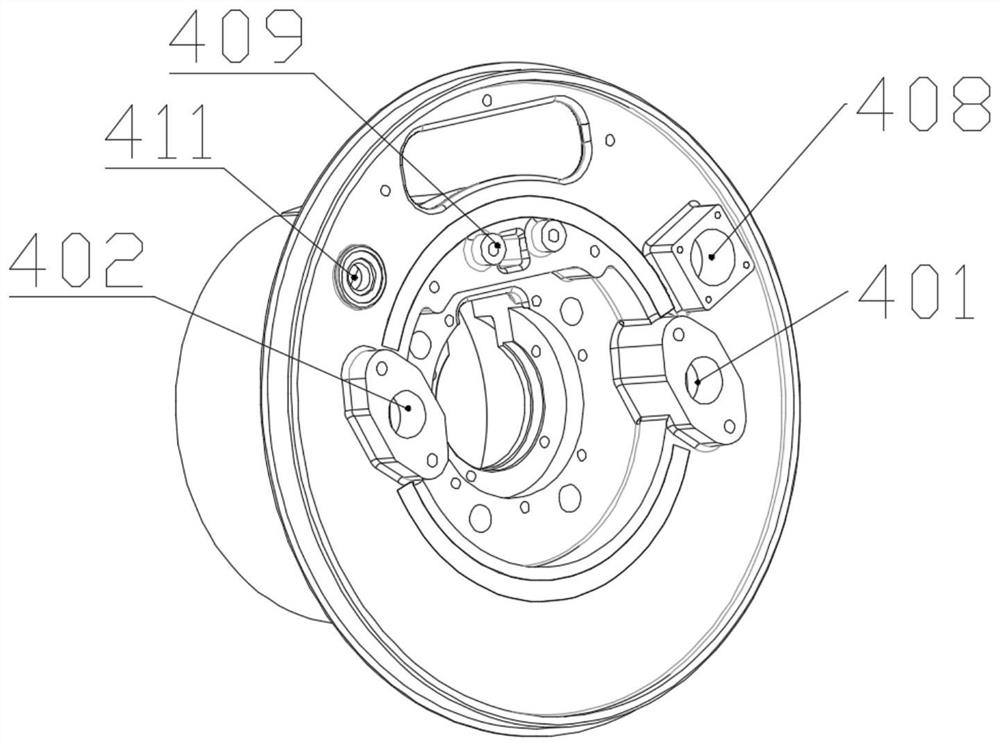

[0033] Such as Figure 2-5 As shown, this embodiment provides a hub motor stator support with a low water resistance cooling structure, including pipe walls and end faces that are perpendicular to each other and fixedly arranged, and the upper half of the circumferential flow channel 405 and the lower half of the circumferential flow channel 405 are symmetrically arranged in the pipe wall. The flow channel 406 is symmetrically provided with a water inlet 401 and a water outlet 402 on the end surface, and the water inlet end of the upper half-circumferential flow channel 405 and the water inlet end of the lower half-circumferential flow channel 406 are both passed through the first axial flow channel. The channel 403 communicates with the water inlet 401 , and the water outlet end of the upper half circumferential flow channel 405 and the water outlet end of the lower half circumferential flow channel 406 communicate with the water outlet 402 through the second axial flow channe...

Embodiment 2

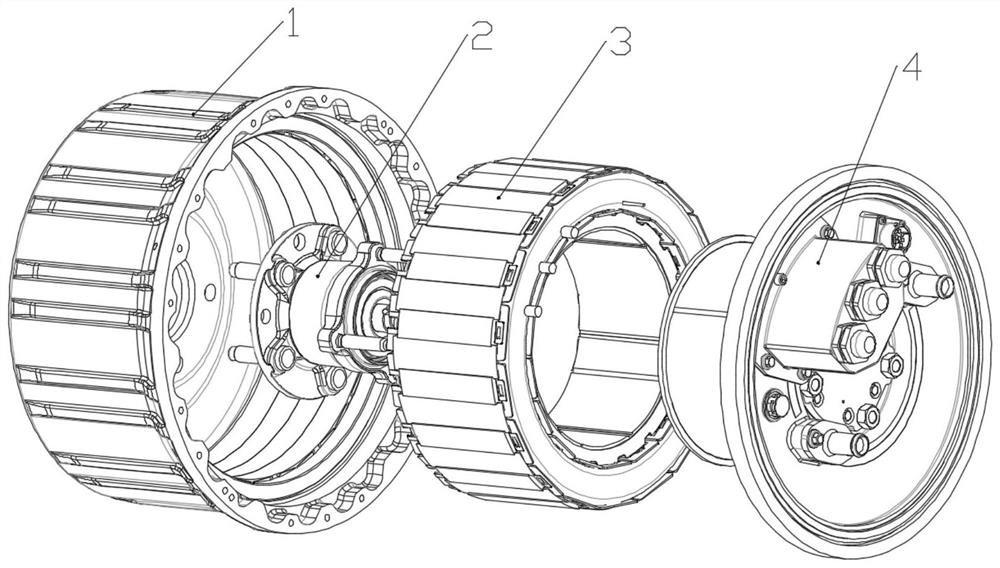

[0046] Such as figure 1 As shown, this embodiment is based on the stator support 4 of the first embodiment, and also provides a hub motor, including the stator support 4 described in the first embodiment, and also includes the rotor assembly 1, the hub bearing assembly 2 and the stator armature assembly 3, the rotor assembly 1, the stator armature assembly 3, the stator support 4 and the hub bearing assembly 2 are nested from outside to inside, and the outer ring of the hub bearing assembly 2 and the stator support 4 Fixedly connected and connected to the vehicle body through a connecting piece, one end of the inner ring of the hub bearing assembly 2 extends radially, and its extended end is connected with the rotor assembly 1 through the wheel.

[0047] The rotor assembly 1 is fixedly connected to the inner ring of the hub bearing assembly 2 by five studs, and the end face of the stator support 4 is fixed to the outer ring of the hub bearing assembly 2 by four studs The stat...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com