Method and system for heat transfer

A heat exchanger, a certain amount of technology, applied in the direction of cleaning heat transfer devices, chemical instruments and methods, preheating, etc., can solve the problems of wasting water, heat and compounds, and achieve the effect of reducing costs and reducing the amount of compounds

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

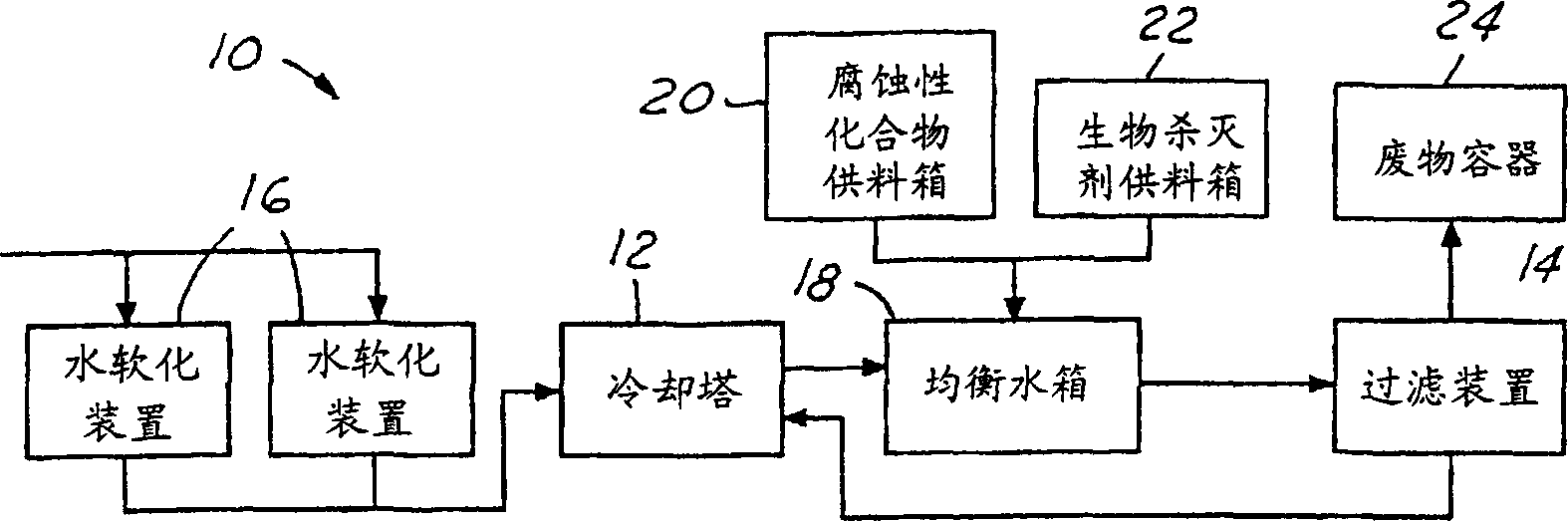

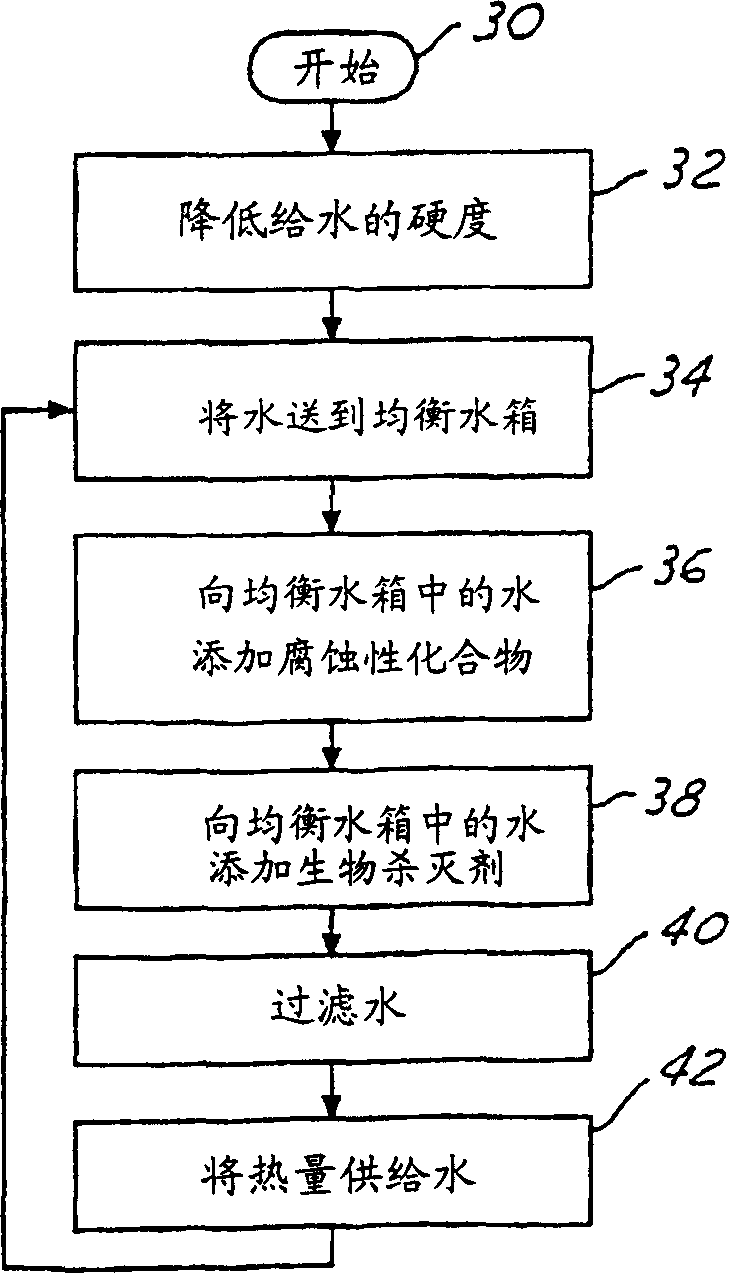

[0019] In the following drawings, the same reference numerals are used to denote the same components in each figure. The present invention is particularly applicable to cooling towers 12 . Of course, it is conceivable that the invention may also be used with various other heat exchangers such as boilers.

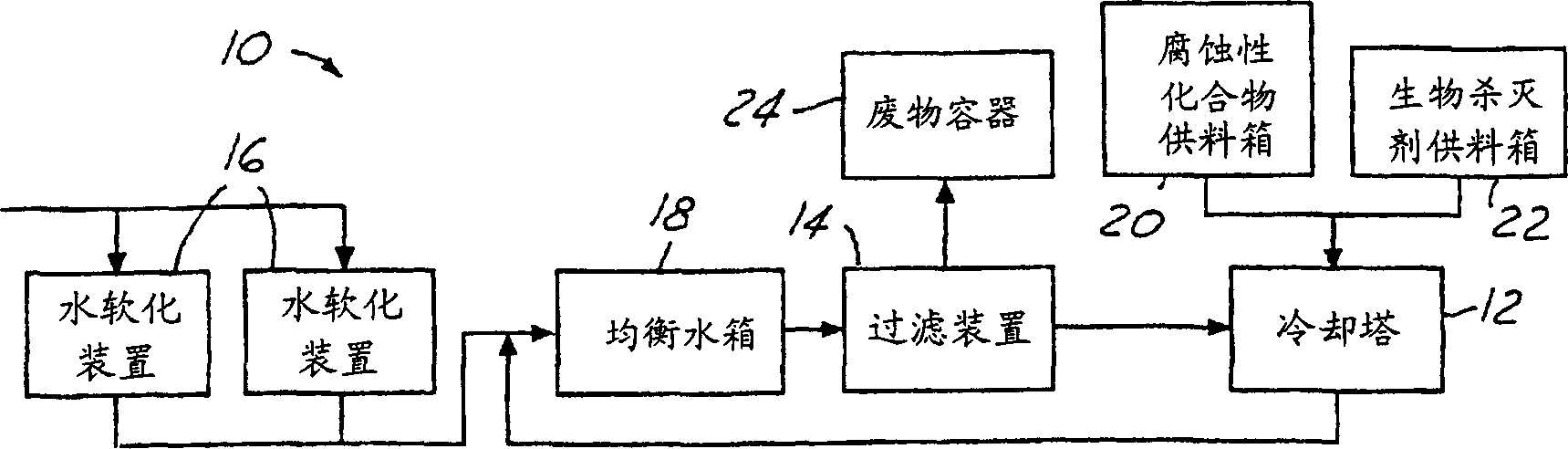

[0020] refer to figure 1 , which schematically illustrates a system 10 utilizing a filtration device 14 and a water softening device 16 to pre-treat feedwater and improve the efficiency of a cooling tower 12 . System 10 preferably includes two water softening units 16 that are used to pre-treat the feedwater prior to heat transfer in cooling tower 12 . Of course, it is conceivable that the system 10 could instead include only one water softening device 16, or more than two water softening devices 16, as desired.

[0021] Water softeners use ion exchange technology to reduce hardness. As is understood by those skilled in the art, water softening devices remove minerals su...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com