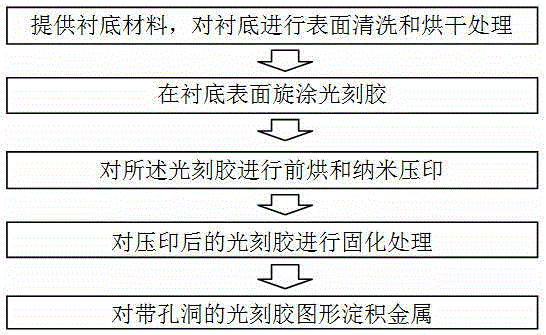

A method for obtaining full-color-spectrum structural color through preparing metal holes having a chassis by utilizing nano-imprint lithography

A nano-imprinting and structural color technology, applied in the field of material technology and nano-processing, can solve problems such as being unsuitable for industrial production, difficult, and inefficient.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

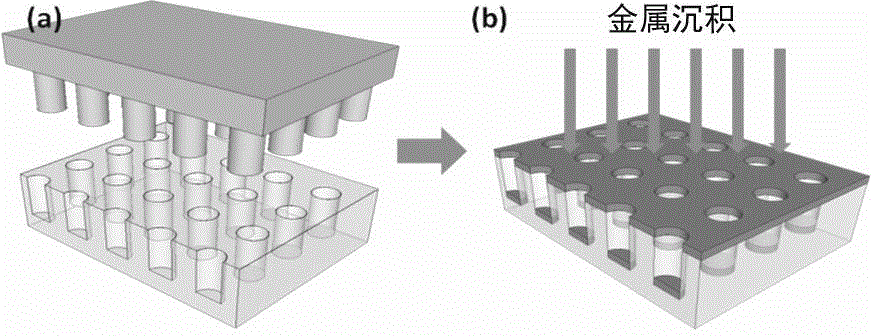

Method used

Image

Examples

Embodiment 1

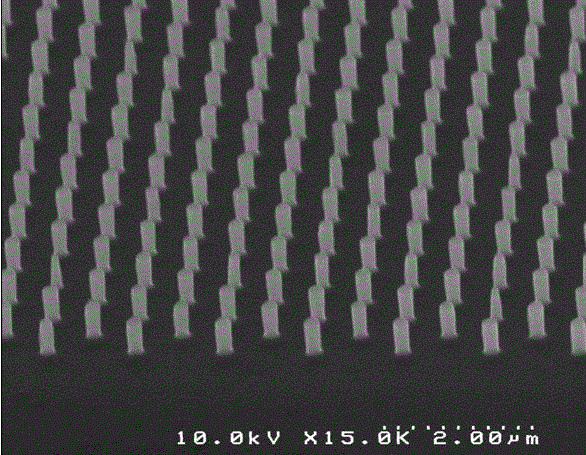

[0028] In this exemplary embodiment: use quartz as the substrate, the PMMA photoresist is a nanoimprint photoresist, and the selected nanostructure is a series of square-arranged hole patterns with different diameters / periods, and the size is represented by a diameter of 10 nanometers / period. Period 20nm is variable 100nm / 200nm, 110nm / 220nm, ..., 250nm / 500nm:

[0029] (1) Routinely clean the quartz plate substrate material, and place it on a 150 hot plate for 5 minutes to dry;

[0030] (2) Spin-coat PMMA photoresist on the surface of the silicon substrate at a spin speed of 1500 rpm for 60 seconds to obtain a photoresist with a thickness of 200 nanometers;

[0031] (3) Pre-baking the spin-coated PMMA photoresist in an oven at a temperature of 180 degrees Celsius for 60 seconds; The printing pressure is 80bar, and the printing time is 5 minutes;

[0032] (4) No special photoresist curing treatment is required for PMMA photoresist;

[0033] (5) Perform thermal evaporation of ...

Embodiment 2

[0035] In this exemplary embodiment: use quartz as the substrate, the SU-8 photoresist is a nanoimprint photoresist, and the selected nanostructures are a series of square-arranged hole patterns with different diameters / periods, and the size is represented by a diameter of 10 nm / period 20nm as variable 100nm / 200nm, 110nm / 220nm, ..., 250nm / 500nm:

[0036] (1) Routinely clean the quartz plate substrate material, and place it on a 150 hot plate for 5 minutes to dry;

[0037] (2) Spin-coat SU-8 2000.5 photoresist on the surface of the silicon substrate at a spin speed of 3000 rpm for 60 seconds to obtain a photoresist with a thickness of 500 nm;

[0038] (3) Pre-baking the spin-coated PMMA photoresist in an oven at a temperature of 150 degrees Celsius for 60 seconds; The printing pressure is 50bar, and the printing time is 5 minutes;

[0039] (4) Perform UV curing on the imprinted SU-8 photoresist for 5 minutes;

[0040] (5) Perform thermal evaporation of the aluminum metal fil...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com