Flexible pressure sensor with complementary spiral structure, preparation method and application thereof

A pressure sensor and helical structure technology, which is applied in the fluid pressure measurement, instrument, and measurement force using capacitance change, can solve the problems of electrode ductility and mechanical strength that limit the application of graphene electrodes, reduce sensor performance, and reduce flexibility. Achieve the effects of excellent flexibility, strong ductility, low cost, and good mechanical tensile properties

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

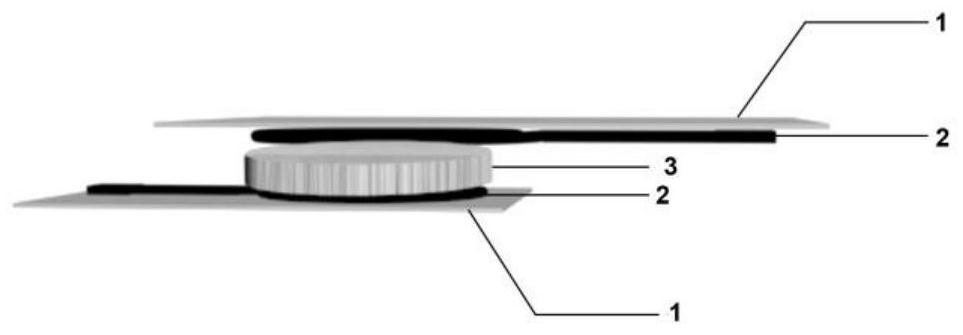

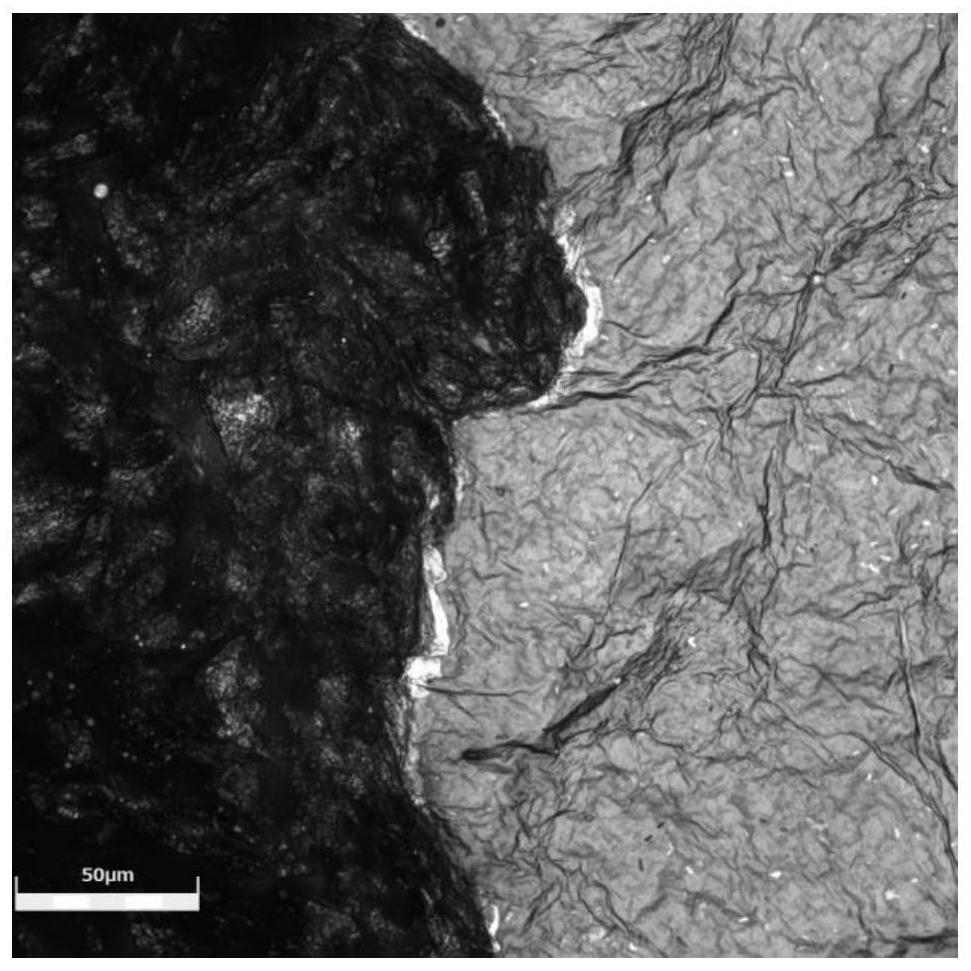

[0051] A flexible pressure sensor with a complementary helical structure, the flexible pressure sensor is composed of upper and lower composite electrodes and a dielectric layer, the composite electrode is composed of a composite film material 1 and a nano-helical structure 2, the dielectric layer It is a porous material 3, and the composite film material 1 is a composite film material with a smooth surface formed by mixing graphene oxide solution and silk fibroin solution and suction filtration; the composite film material 1 has a nanohelical structure 2 formed on the surface, and the composite film material 1 has a nanohelical structure 2. The outer surface of the film material 1 and the nano-helical structure 2 is adhered with a porous material 3, and the upper and lower electrodes and the dielectric layer form a composite film material 1-nano-helical structure 2-porous material 3-nano-helical structure 2-composite film material 1 multilevel micro-nano structures.

[0052] ...

Embodiment 2

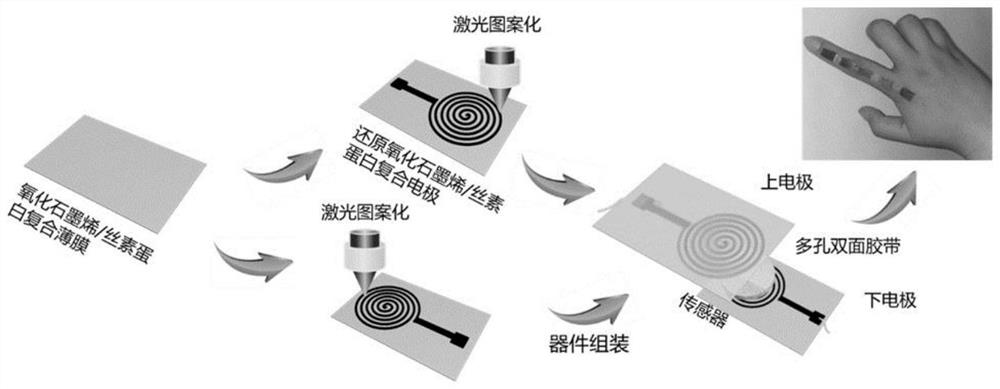

[0057] like figure 1 As shown, a method for preparing a flexible pressure sensor with a complementary helical structure based on laser processing, the specific steps are as follows:

[0058] (1), the preparation of graphene oxide / silk fibroin mixed solution;

[0059]Use a rubber dropper to draw 20 mL of graphene oxide solution with a concentration of 8 mg / mL and put it into a beaker with a capacity of 100 mL, and then add 3 mL of sodium hydroxide solution with a concentration of 0.05 mol / L dropwise to make the pH of the graphene oxide solution value is 7, then add 2mL of silk fibroin solution with a concentration of 40mg / mL, then put the beaker containing the graphene oxide / silk fibroin mixture on a magnetic stirrer and stir for 10s-1min, after mixing evenly, the oxidized Graphene / Silk Fibroin Hybrid Solution.

[0060] Wherein, the graphene oxide solution used is synthesized by Hummer's method, and the specific synthesis steps are as follows: firstly, graphite and sodium nit...

Embodiment 3

[0071] This embodiment provides an application of a flexible pressure sensor with a complementary helical structure based on laser processing for finger bending detection. The specific steps are as follows:

[0072] First, use 3M adhesive tape to attach the helical complementary structure pressure sensor to the joint of the index finger (attached when the finger is straight), and then connect the wires at both ends of the helical complementary structure pressure sensor to the LCR-6200 digital bridge tester, and use a protractor to calibrate The bending angle of the index finger joint, when the finger joint is bent at 0°, 30°, 60°, and 90°, the relative change of the capacitance of the pressure sensor with the helical complementary structure (ΔC / C 0 ) are 0, 0.21, 0.33, 0.48 respectively; when the finger is bent, the parallel plate capacitor It can be obtained that the distance d between the upper and lower electrodes decreases during bending, and at the same time, the air wit...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Thickness | aaaaa | aaaaa |

| Aperture | aaaaa | aaaaa |

| Aperture | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com