Nanoscale resistance spot welding device and nanoscale resistance spot welding method

A resistance spot welding, nano-scale technology, applied in resistance welding equipment, nanotechnology, nanotechnology and other directions, can solve the problems of scrapped components, disconnected metal wires, unreliable connection strength, etc., to achieve simple operation and low cost. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0024] The present invention will be further described in detail below in conjunction with specific embodiments and accompanying drawings.

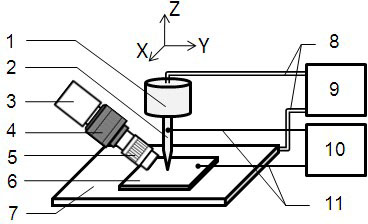

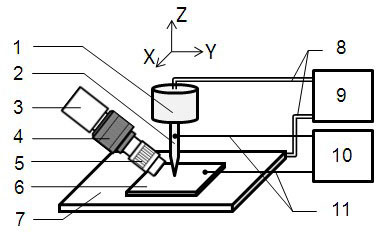

[0025] figure 1 The schematic diagram of the nanoscale resistance spot welding device is given. according to figure 1 , the nanoscale resistance spot welding device consists of scanning probe 2, CCD camera 3, zoom module 4, magnifying objective lens 5, scanning probe microscope control and feedback connection 8, scanning probe microscope control and feedback module 9 , The welding control power supply 10 and the welding power supply wire 11 are composed. The XYZ direction action module 1 moves the scanning probe 2 , and the processed workpiece 6 is fixed on the stage 7 .

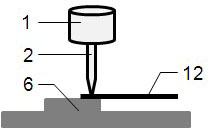

[0026] figure 2 An example of spot welding of a cantilever beam in a micro-nanoarchitecture is given. according to figure 2 As shown, the workpiece 6 to be processed is a silicon substrate with certain nanostructure protrusions, and its surface layer is evenly c...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com