Plasma nano-structure assisted femtosecond laser nano-manufacturing method and system

A femtosecond laser and nanostructure technology, applied in the field of femtosecond laser nanoprocessing, can solve the problems of limited cost of processing materials, high processing environment requirements, and difficulty in breaking through the optical diffraction limit, and achieve a wide range of processing materials and simple processing technology Easy-to-do, easy-to-control effects

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

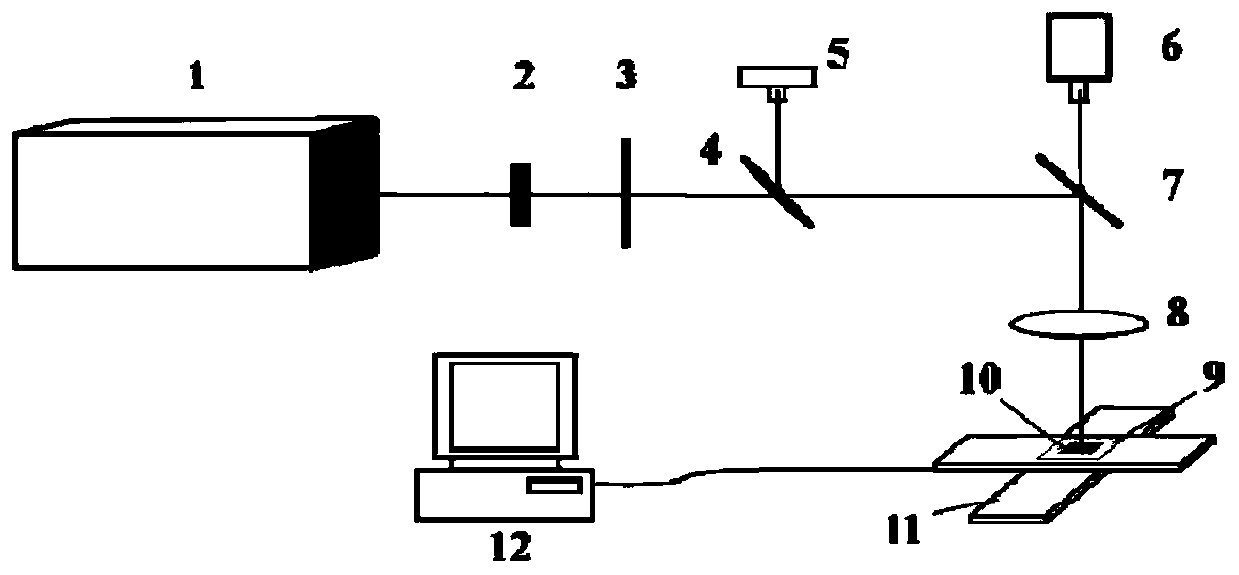

[0052] The present invention will be further described in detail below in conjunction with the accompanying drawings and specific embodiments.

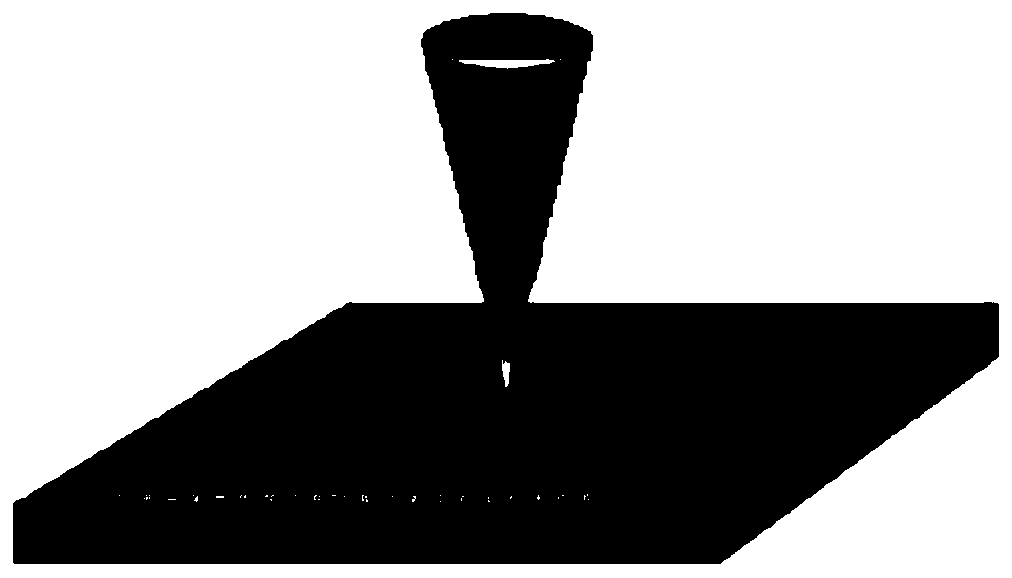

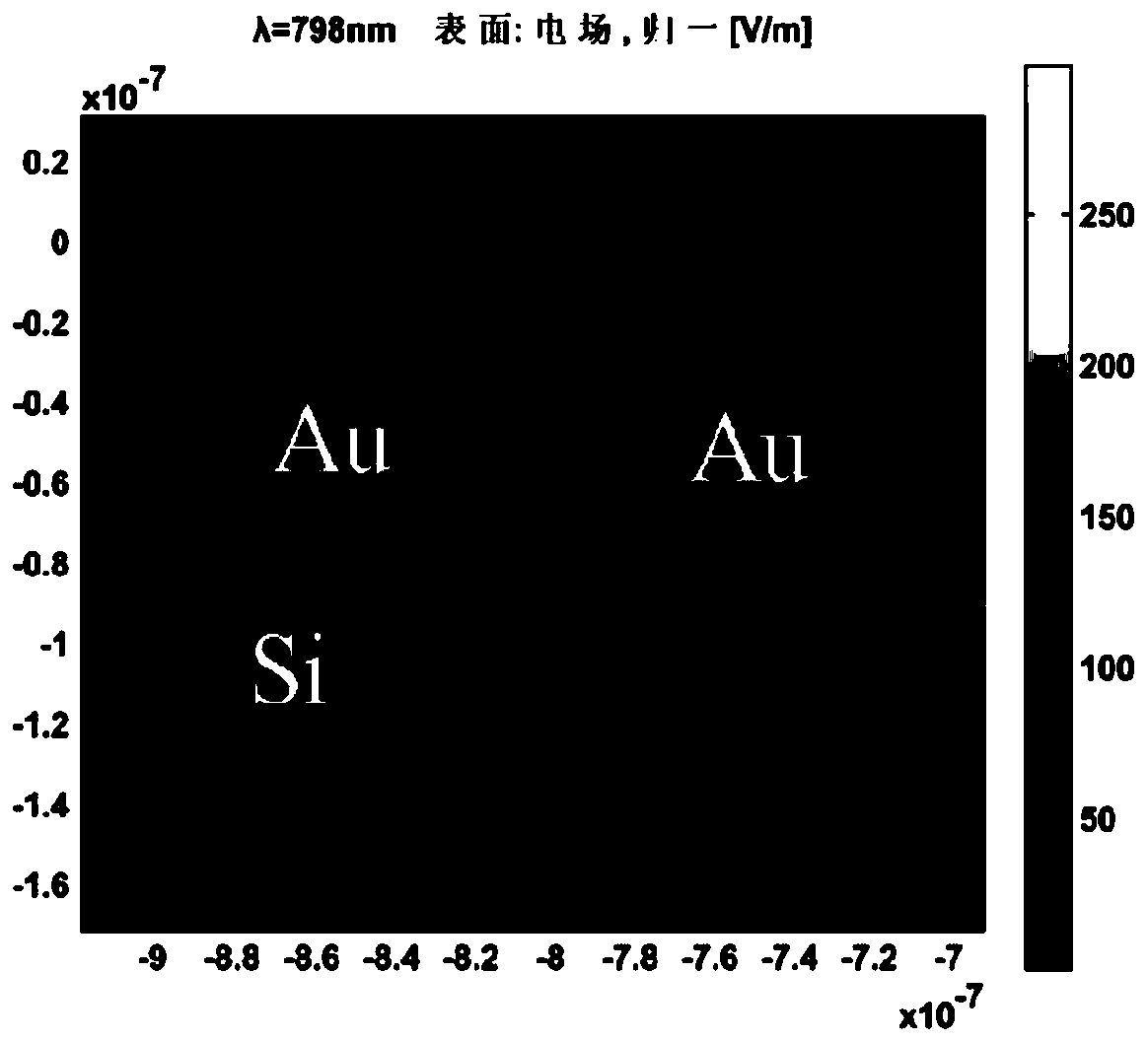

[0053] The invention focuses the femtosecond laser on the plasma nanostructure, induces local surface plasmon resonance thermal field enhancement in the plasma nanostructure through the femtosecond laser, and forms a local field enhancement beyond the optical diffraction limit on the surface of the material to be processed, realizing Diffraction-limited-scale nanofabrication of substrate materials. Any material including hard and brittle materials can be surface-arrayed and patterned with ultra-high-resolution nanofabrication in free space to obtain specific processing patterns.

[0054] In this embodiment, the Au nano-grating structure is used as the plasmonic nano-structure, and the Si material is used as the material to be processed, and is realized through the following steps:

[0055] 1) Select the Si material to be processed, a...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

| width | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com