Point diffraction interferometer

A point diffraction interferometer, diffracted light technology, applied in instruments, measurement devices, optical devices, etc., can solve the problem that measurement results are easily affected by the environment, simplify design and operation, avoid motion errors, and improve sampling frequency Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

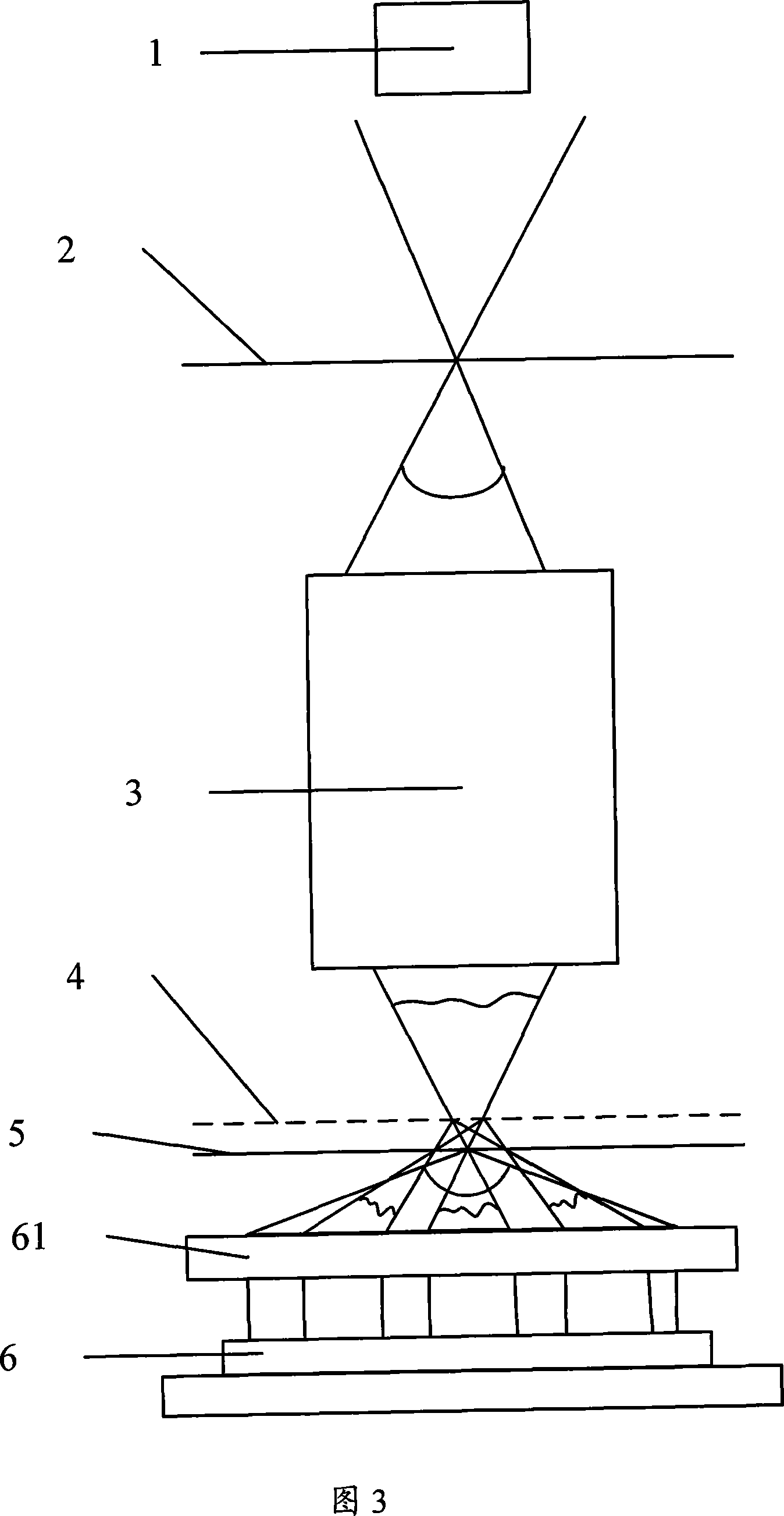

[0024] The point diffraction interferometer of the present invention will be further described in detail in conjunction with several preferred embodiments below. In the following embodiments, the point diffraction interferometer of the present invention is specifically an objective lens detection interferometer, which uses an optical fiber as a transmission optical path to generate a standard wavefront, and uses a common path interference system to realize the aberration detection of the projection objective lens. The specific device is as follows:

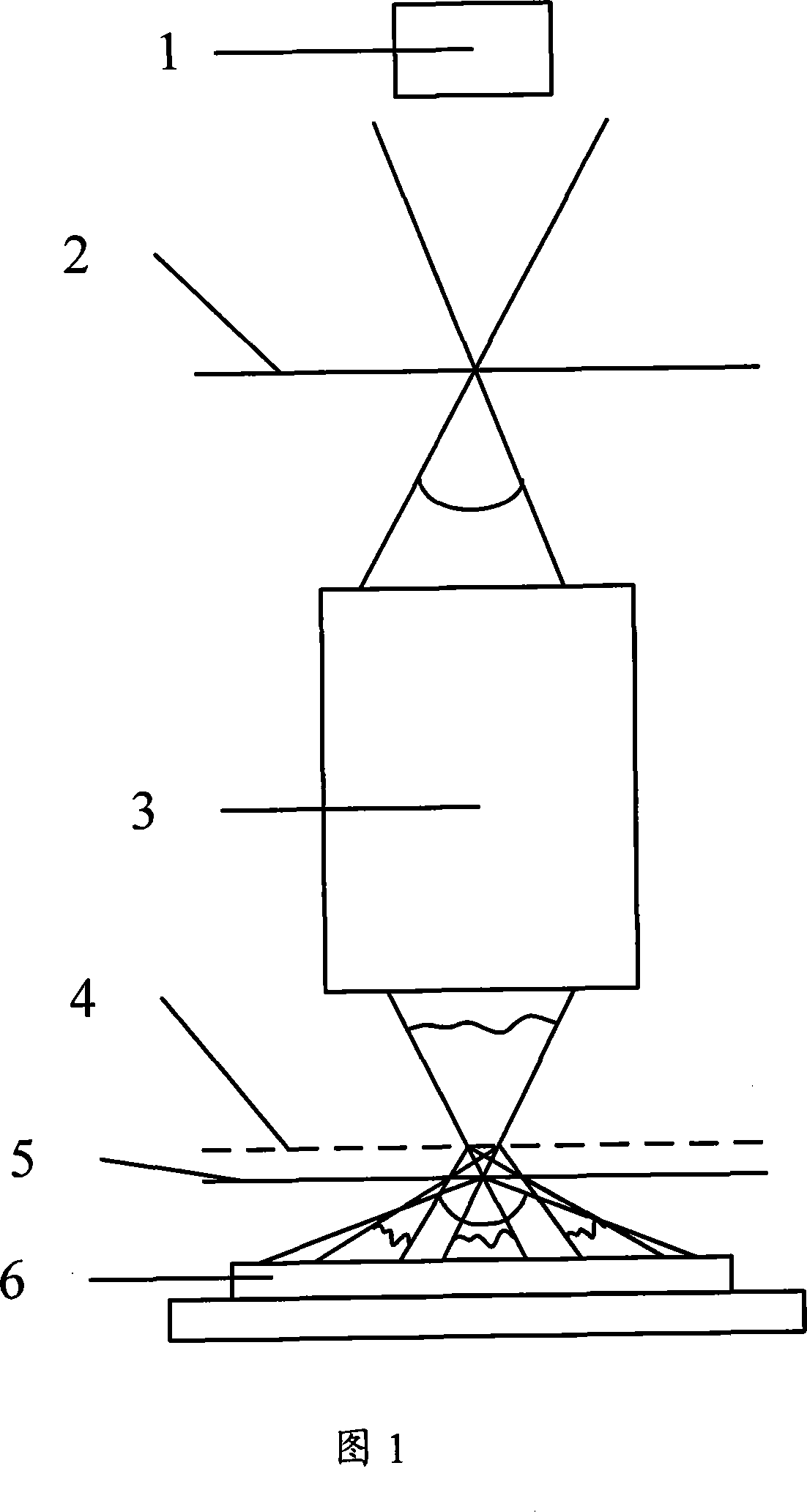

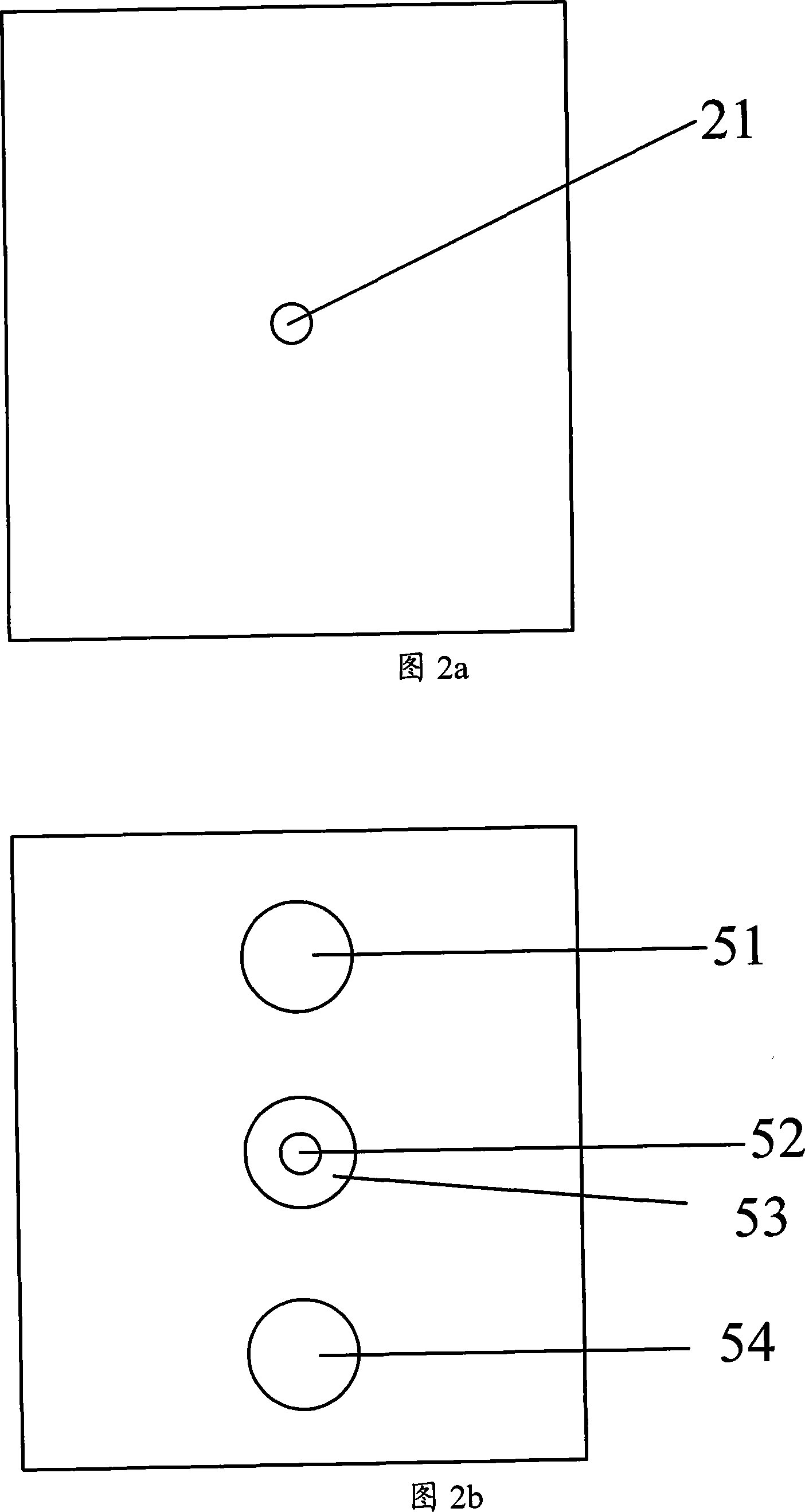

[0025] Please refer to FIG. 1 first. FIG. 1 is an overall structural diagram of a projection objective lens inspection system according to a first embodiment of the present invention. The light emitted by the light source module 1 passes through the mask 2, and a small hole is placed on the mask, and the small hole produces diffraction, and the diffracted light enters the optical system under test 3, passes through the optical sys...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com