Sample precise jig for cross-scale two-photon polymerization machining and leveling method

A two-photon polymerization, cross-scale technology, applied in the direction of manufacturing tools, metal processing equipment, laser welding equipment, etc., can solve the problems of complex structure, low precision, and difficulty in effectively realizing high-precision two-photon polymerization cross-scale processing, reaching the position Flexible and adjustable to meet the actual height needs

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

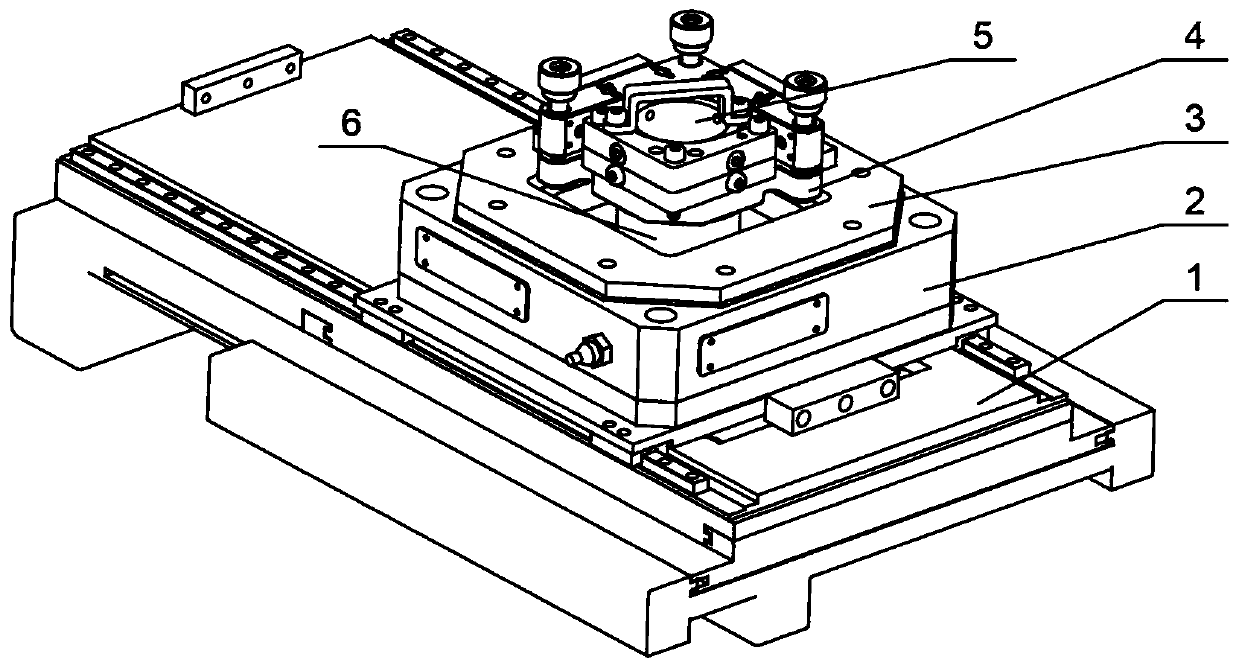

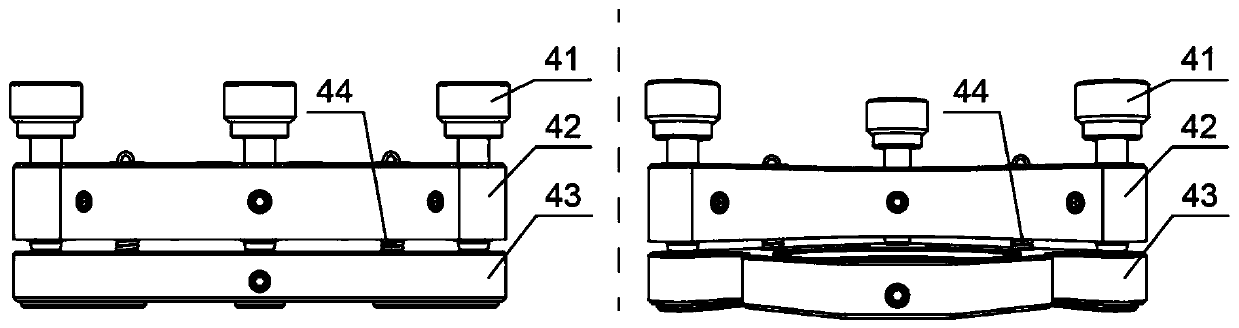

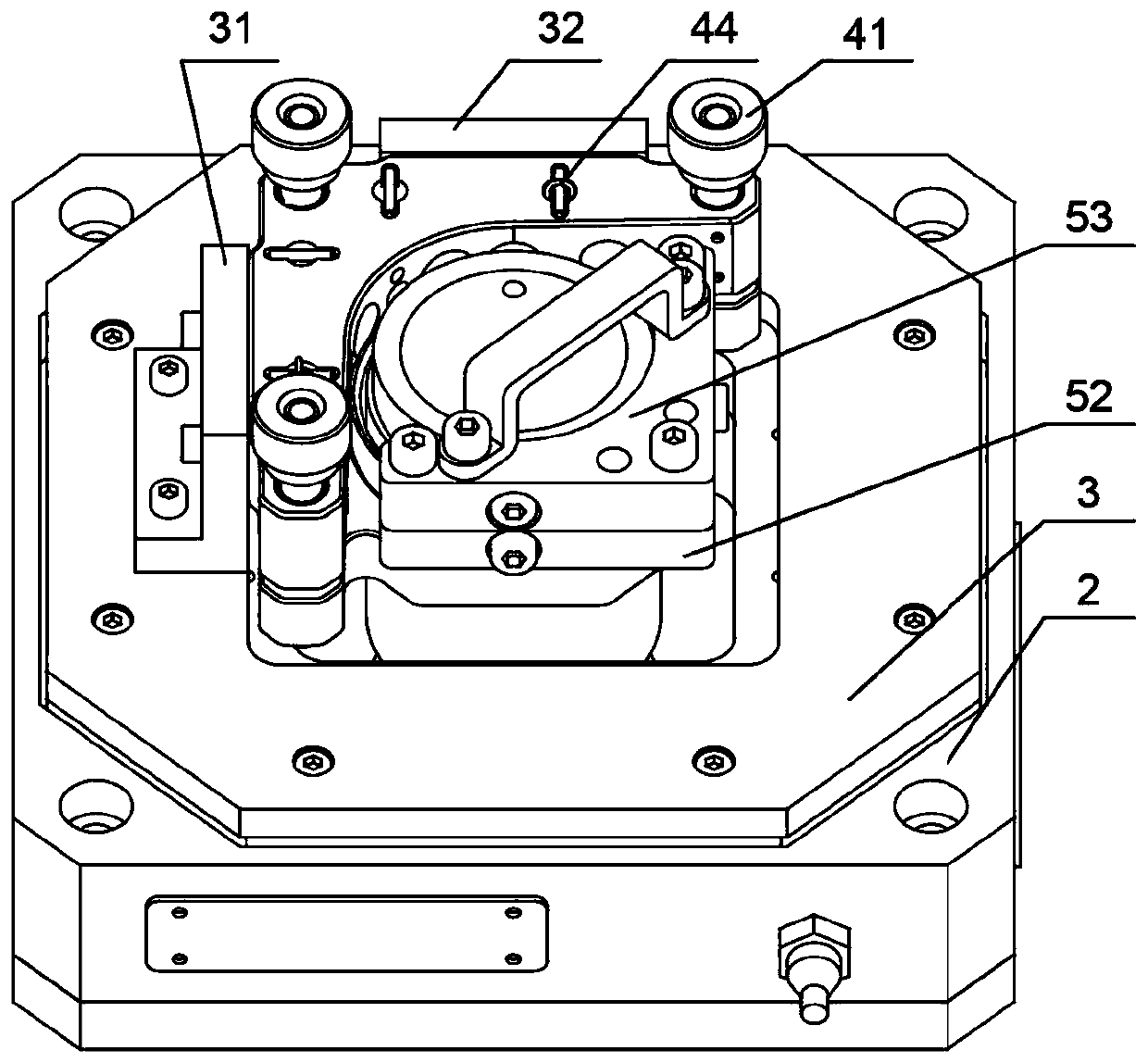

[0041] A sample precision fixture used for cross-scale two-photon polymerization processing, such as figure 1 As shown, it includes: fixedly connected XY-axis moving platform 1, Z-axis translation stage 2, and base plate 3, fine adjustment assembly 4, transition assembly 5, and stage 6 arranged on the base plate 3; wherein one end of the transition assembly is fixed Fix the stage on the other end of the fine-tuning assembly. Among them, the XY-axis moving platform is used to drive the Z-axis translation stage and the substrate to move in the X-axis and Y-axis directions; the Z-axis translation stage is used to drive the substrate to drive the fine-tuning components, transition components and the stage to move in the Z-axis direction; The component is used to drive the stage to achieve levelness and flatness adjustment by driving the transition component.

[0042] The XY-axis moving platform can drive the Z-axis stage to move along the X-axis and Y-axis directions; the Z-axis stag...

Embodiment 2

[0054] A sample leveling method for cross-scale two-photon polymerization processing, including:

[0055] The focus measurement module installed on the optical platform is used to focus and collect the relative height between the stage and the sample in any sample precision tool for cross-scale two-photon polymerization processing as described in the first embodiment; The relative height is calculated, the levelness and flatness error of the stage are calculated, and the electric fine-tuner in the precision fixture is driven to level; after multiple iterations, the working surface of the stage and the focus measurement The incident optical axis emitted by the module is vertical; when performing cross-scale processing, the focus measurement module is used to collect the processing height in real time, and the Z-axis translation stage of the precision fixture is driven to calibrate the processing height in real time, so that the sample area to be processed is always maintained In t...

Embodiment 3

[0069] A machine-readable storage medium, the machine-readable storage medium stores machine-executable instructions, when the machine-executable instructions are called and executed by a processor, the machine-executable instructions prompt the processor to implement the above The described sample leveling method for cross-scale two-photon polymerization processing.

[0070] The related technical solutions are the same as in the second embodiment, and will not be repeated here.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com