Method for making nanometer dimension triangle air pocket

A technology of nanometer size and manufacturing method, applied in nanostructure manufacturing, nanotechnology, nanotechnology, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

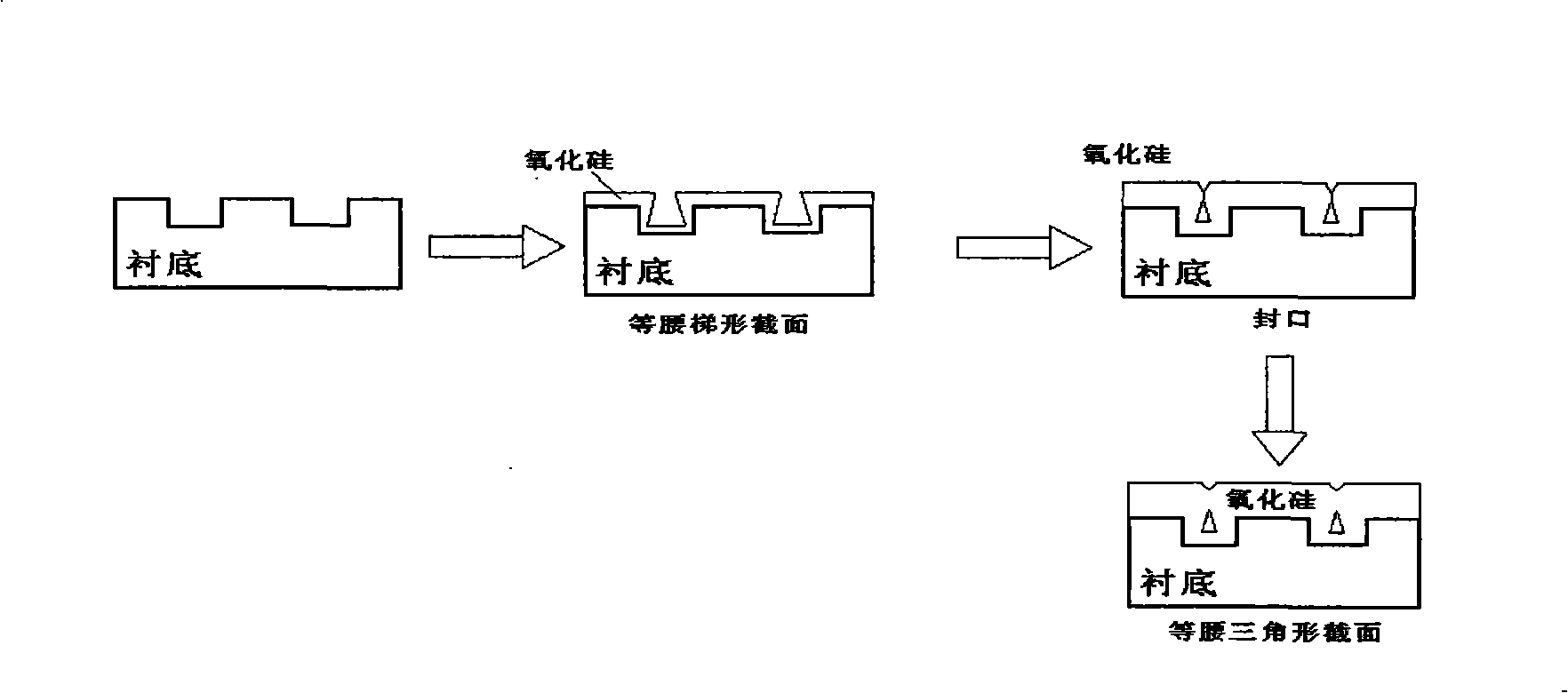

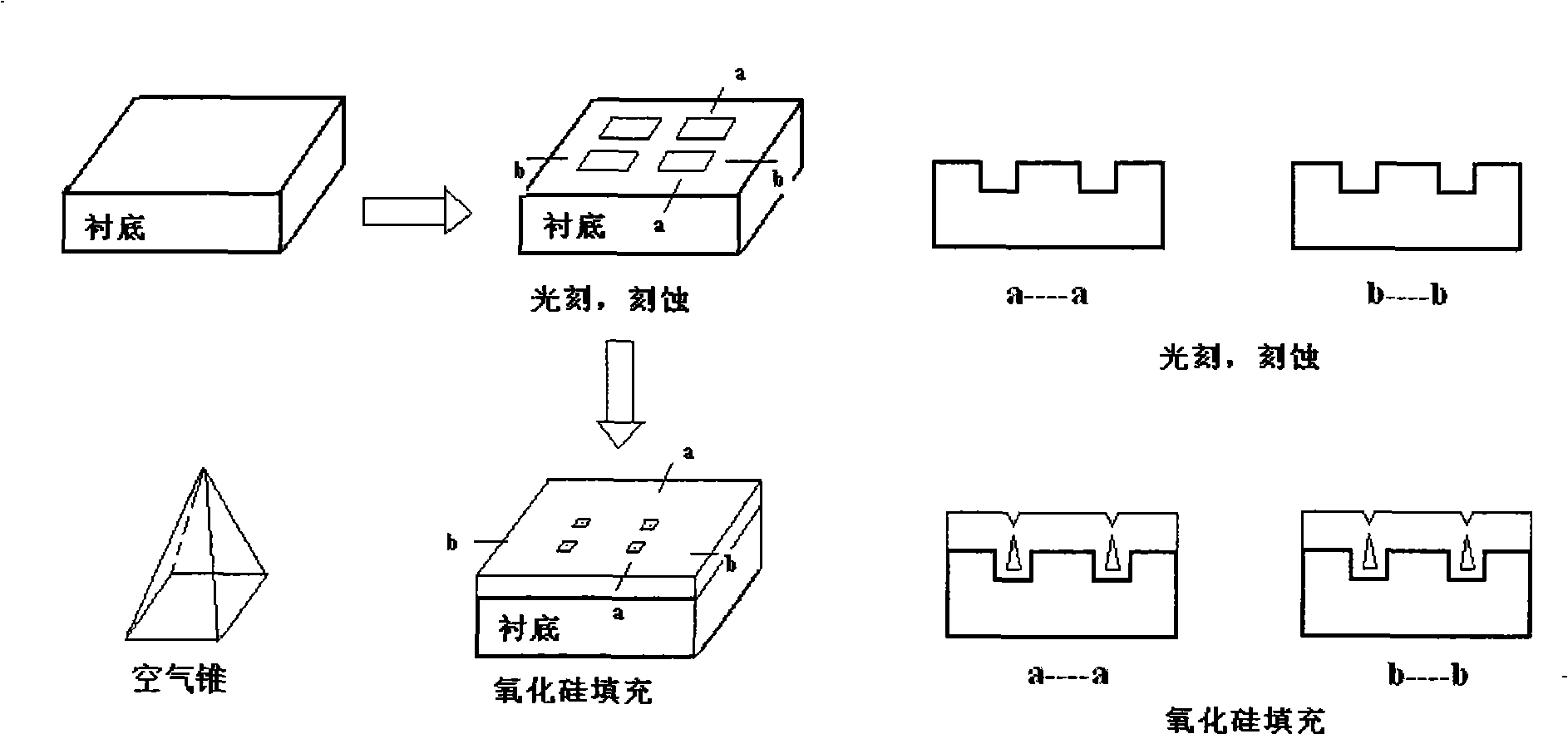

[0042] In order to make the object, technical solution and advantages of the present invention clearer, the present invention will be described in further detail below in conjunction with specific embodiments and with reference to the accompanying drawings.

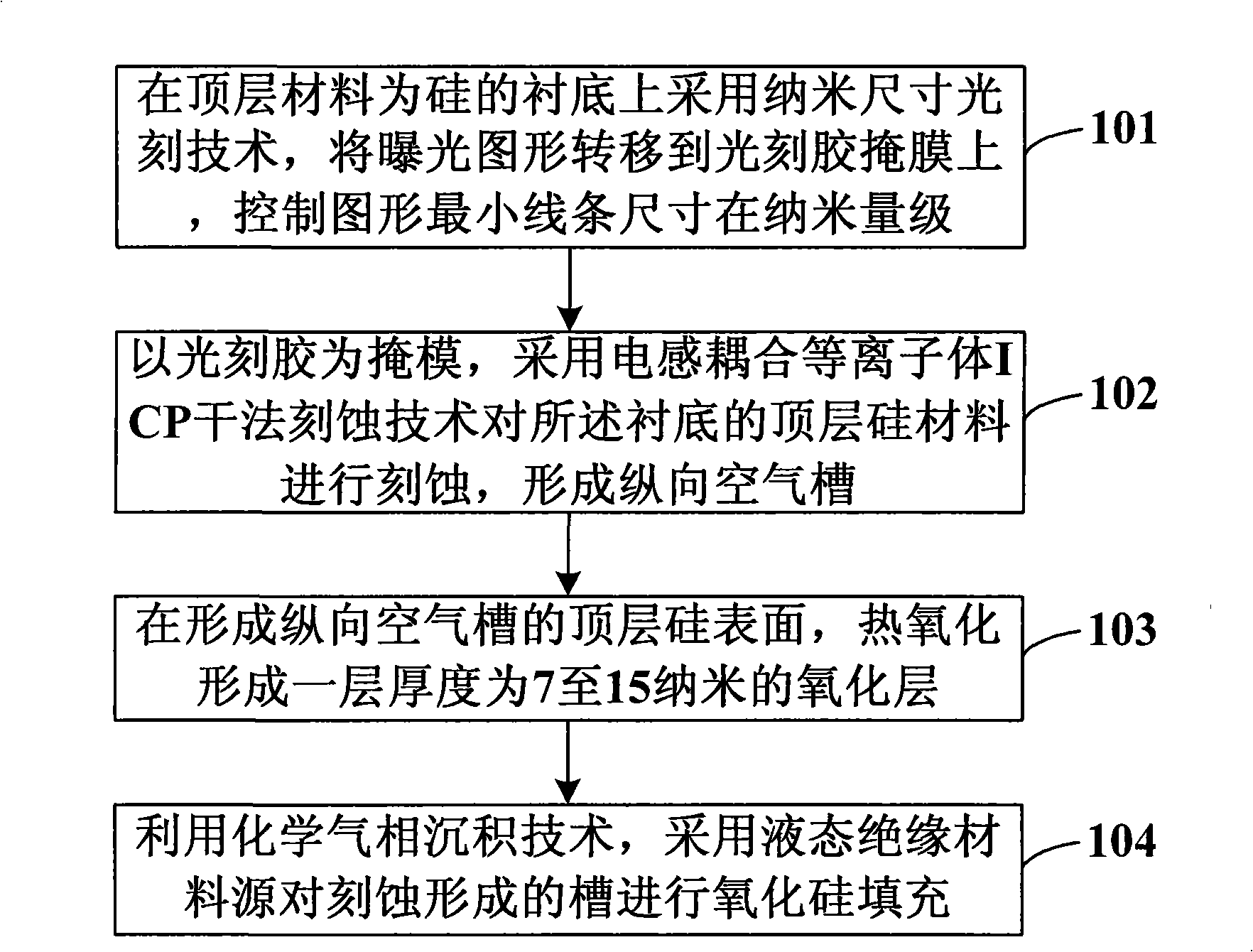

[0043] Such as figure 1 as shown, figure 1 The flow chart of the method for making nano-sized triangular air slots provided by the present invention, the method comprises the following steps:

[0044] Step 101: Using nano-scale photolithography technology on the substrate whose top layer material is silicon, transfer the exposure pattern to the photoresist mask, and control the minimum line size of the pattern to be on the order of nanometers;

[0045] Step 102: using the photoresist as a mask, using inductively coupled plasma ICP dry etching technology to etch the silicon material on the top layer of the substrate to form vertical air grooves;

[0046] Step 103: forming an oxide layer with a thickness of 7 to 15 nanomete...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com