Method and device for measuring appearance and wall thickness of sphere by combining differential confocal and point-diffraction interference

A technology of point diffraction interference and differential confocal, which is used in measurement devices, optical devices, instruments, etc. to improve measurement efficiency, suppress environmental changes, and improve accuracy.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

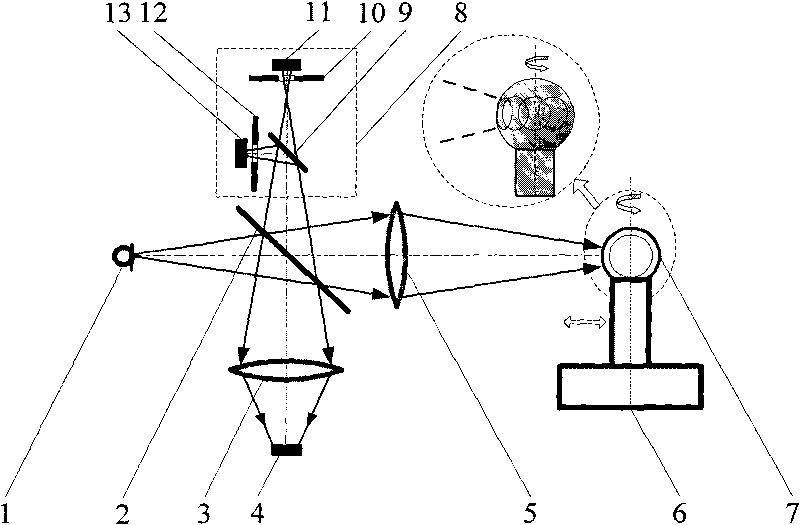

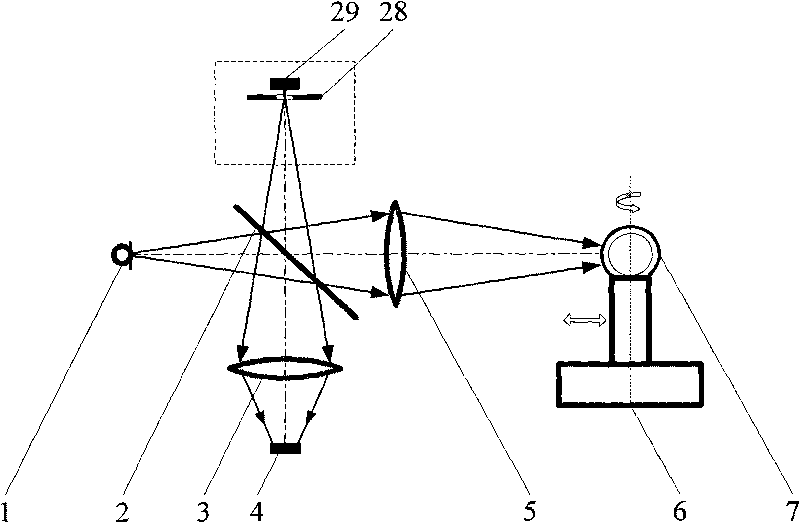

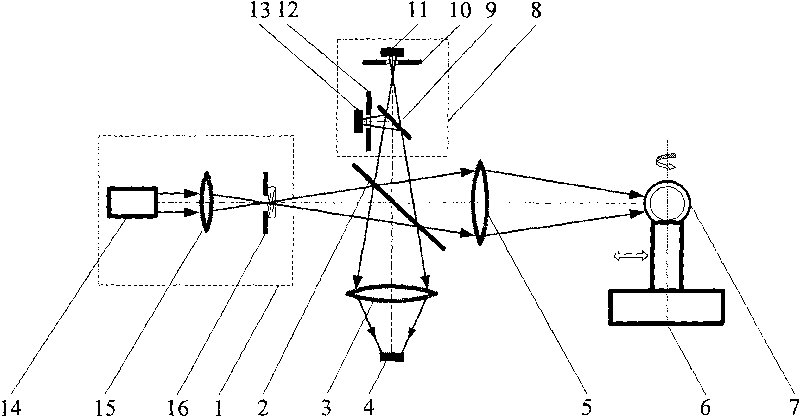

[0052] Such as Figure 4 As shown, the method of combining differential confocal and point diffraction interference to measure the shape and wall thickness of a sphere, the measurement steps are:

[0053] First, the light source 20 is turned on, and the emitted parallel light passes through the phase-shifting system composed of the beam splitter 19, the reflector 17 and the piezoelectric ceramic driving reflector 18, and becomes a phase-shiftable parallel light, and then converges to the optical fiber through the objective lens 21. 22, the light emitted from the output end of the optical fiber 22 passes through the beam splitter 2 and the objective lens 5 successively, and converges on the surface of the hollow sphere 7. It is divided into two parts: one part is reflected to the differential confocal measurement system 8, and the other part is transmitted to the exit end of the optical fiber 22, and after being reflected by the reflection surface of the exit end of the optical...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com