Calibration method of spot scanning three-dimensional topography measuring system

A measurement system and three-dimensional topography technology, applied in the direction of measuring devices, instruments, optical devices, etc., can solve problems such as difficult to obtain calibration results, difficult to accurately align laser points and known reference points, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

specific Embodiment approach

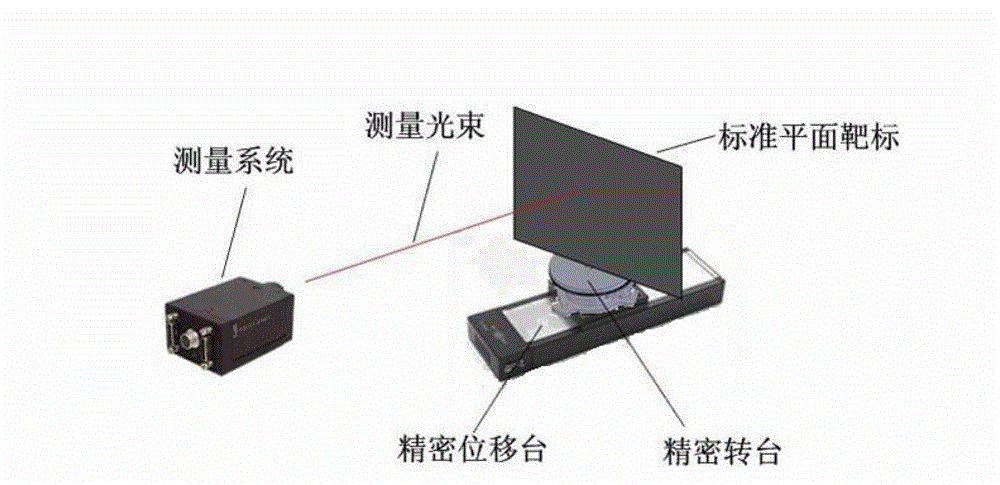

[0041] Aiming at the calibration problem of the point-scanning three-dimensional shape measurement system, a method based on the precise movement and rotation of the standard plane target is used to realize the precise calibration of the system. The specific implementation is as follows:

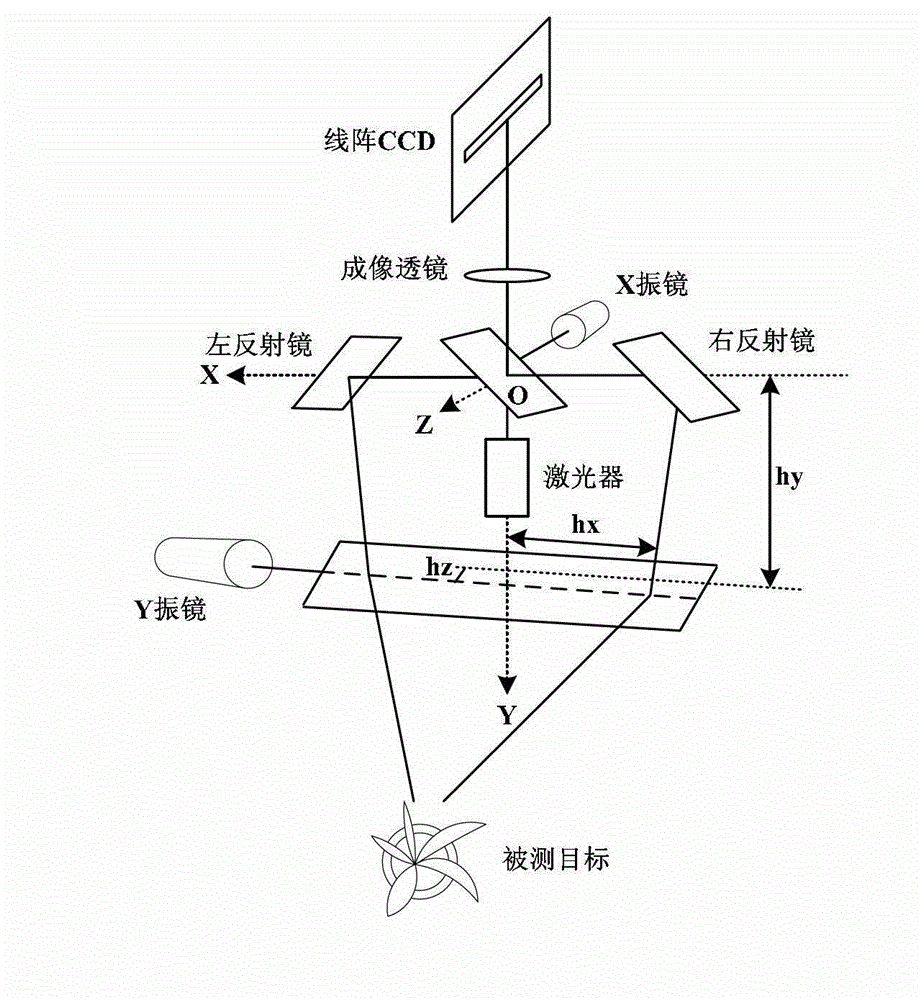

[0042] See figure 1 , a structural schematic diagram of a point-scanning three-dimensional shape measurement system, taking the system as an example to apply the method of the present invention for system calibration.

[0043] See Image 6 , a method for calibrating a point-scanning three-dimensional shape measurement system according to the present invention, the specific steps of the method are as follows:

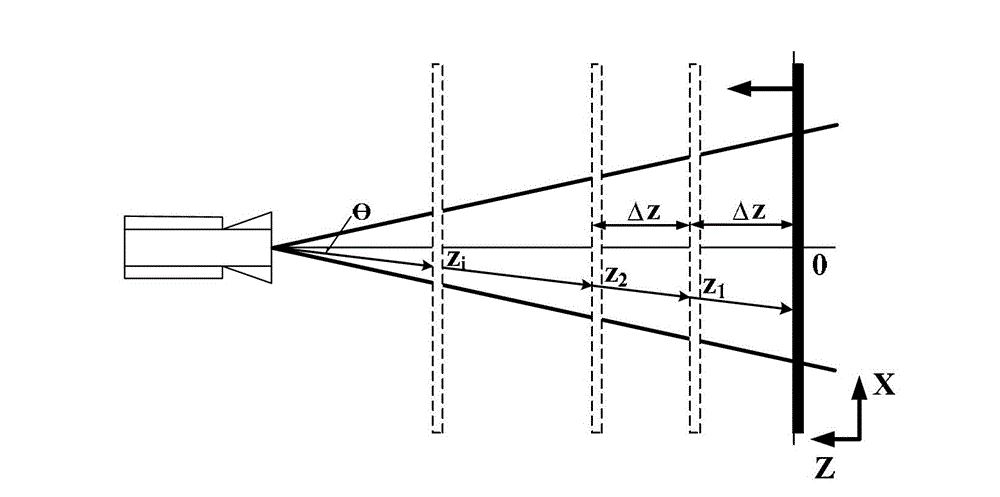

[0044] Step 1: System modeling. Establish a mathematical model according to the system measurement principle, and determine the parameters to be calibrated.

[0045] The beam emitted by the laser passes through the front of the X galvanometer, the left reflector, and the left end o...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com