System and method for processing dynamic focusing scanning spot track of optical fiber laser or disk laser

A dynamic focusing, fiber laser technology, used in laser welding equipment, metal processing equipment, manufacturing tools, etc., can solve the problems of unstable welding spot energy, limited working range, cumbersome equipment integration, etc., to improve welding quality, The effect of large processing range and wide application value

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

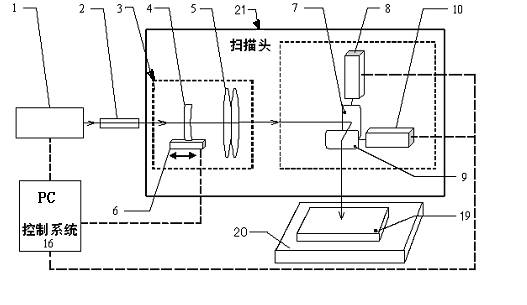

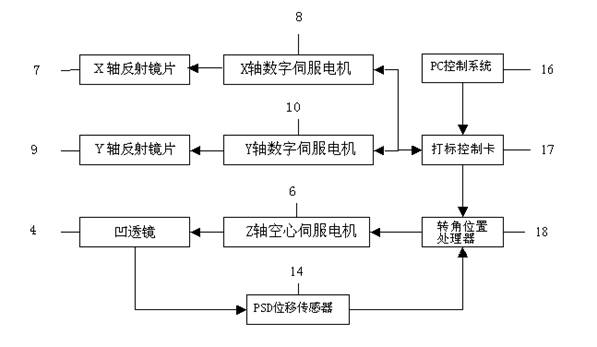

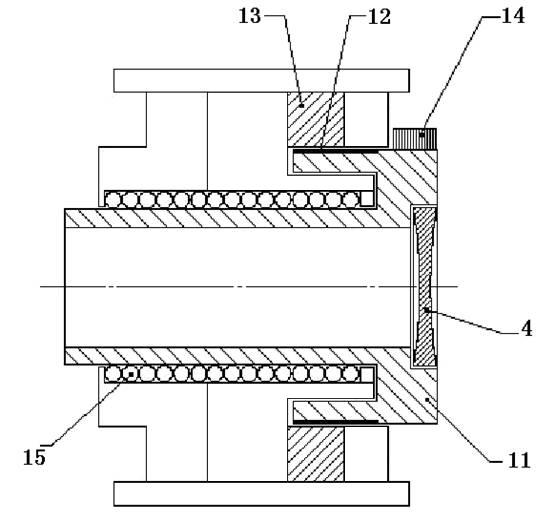

[0019] Depend on figure 1 and figure 2 As shown, a fiber laser or disc laser dynamic focusing scanning point track processing system includes a laser 1, a collimator beam expander 2, a scanning head 21, a PC control system 16, and an object stage 20, wherein the The laser 1 is a fiber laser or a disk laser, the fiber output head of the fiber laser or the disk laser is connected to the collimating beam expander 2, and the collimating beam expander 2 is connected to the scanning head 21; the scanning The head 21 is composed of a Z-axis dynamic focus module 3, an X-axis mirror 7, an X-axis digital servo motor 8, a Y-axis mirror 9, and a Y-axis digital servo motor 10. The X-axis mirror 7 is installed on the X-axis digital On the rotating shaft of the servo motor 8, the Y-axis mirror 9 is installed on the rotating shaft of the Y-axis digital servo motor 10, and the light beam output by the fiber laser or the disk laser is successively passed through the collimating beam expander...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com