Warehousing system based on AGV delivering and loading small handcart and warehousing and warehouse-out method

A warehousing system and small trolley technology, applied in the field of logistics, can solve the problems of low storage efficiency, cumbersome and laborious access to goods, etc., and achieve the effect of rapid scanning, neat logistics and warehousing process, and reduced storage steps

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0043] Embodiments of the present invention will be further described below in conjunction with the accompanying drawings.

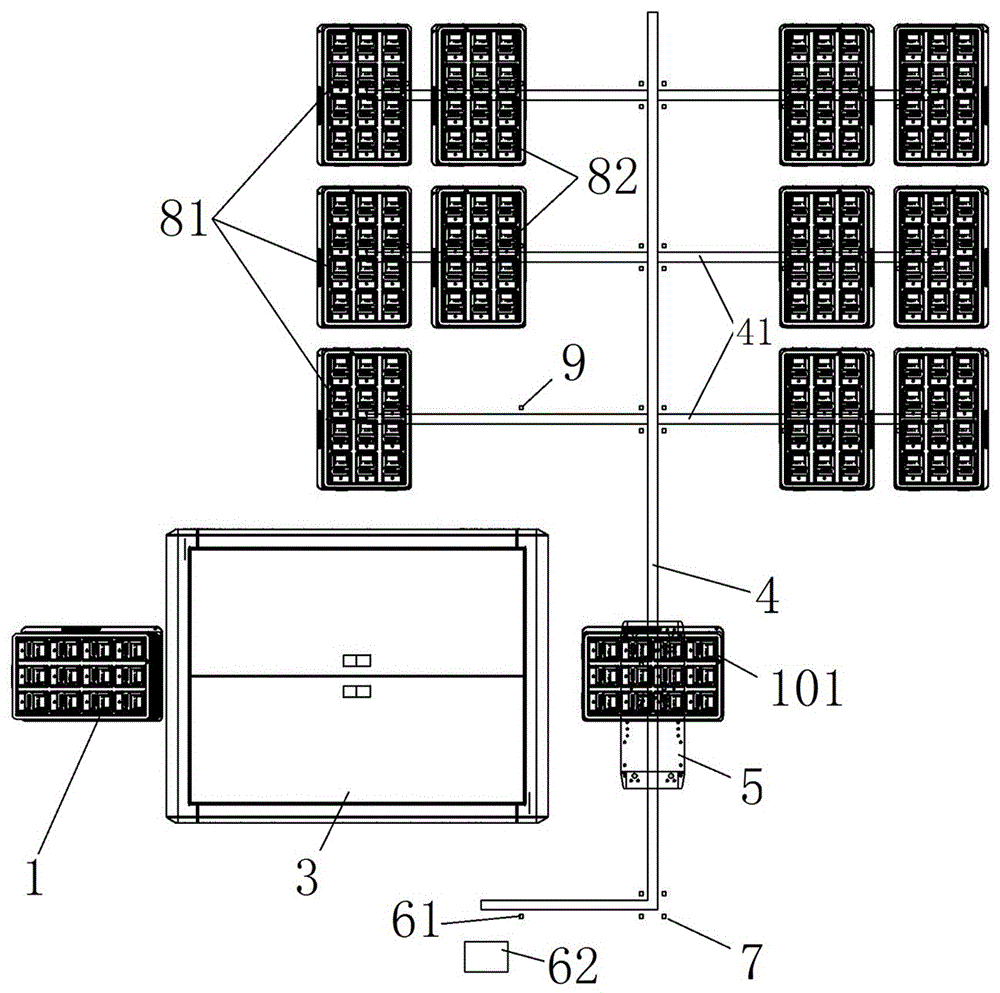

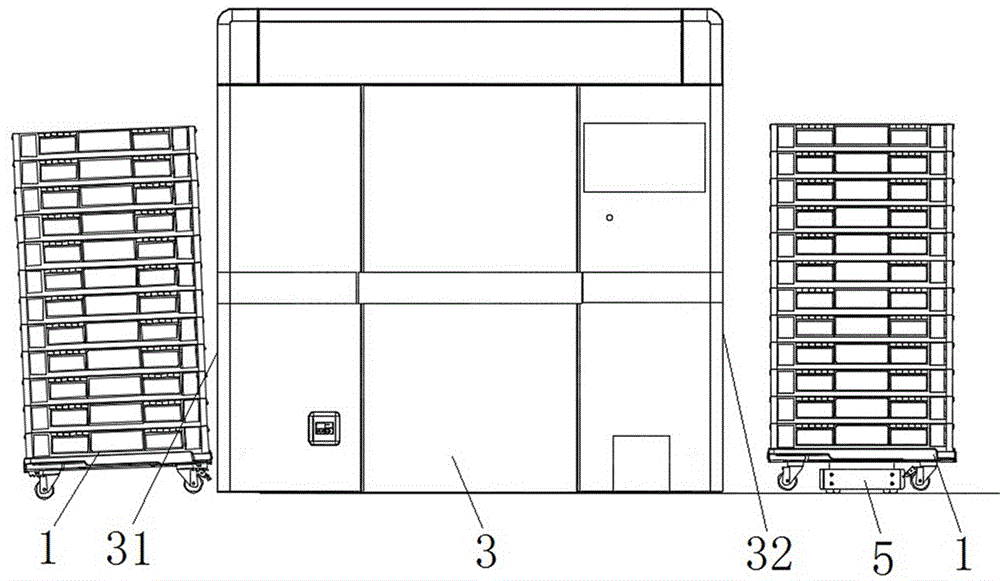

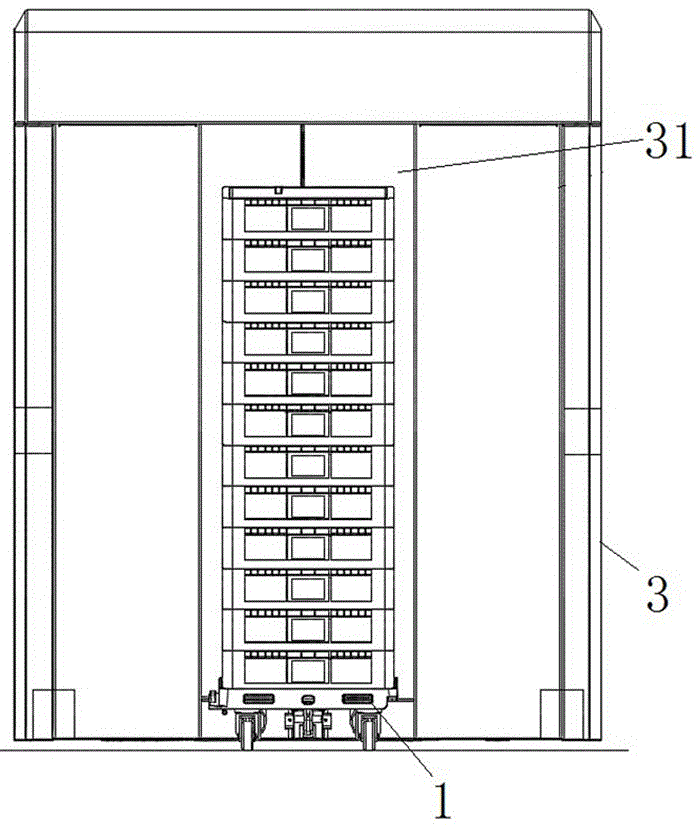

[0044] The specific embodiment of the storage system based on the AGV of the present invention to transport the cargo trolley, as Figure 1 to Figure 10 As shown, it includes a warehouse for storing goods 10, and trajectory lines are arranged on the ground of the warehouse, and the trajectory lines are magnetic tracks or other trajectory lines in the prior art, and will not be described again. Also comprise a plurality of AGV dolly 5 in the trajectory warehouse, the structure of AGV dolly 5 is as follows: Figure 9 and Figure 10 As shown, the front portion has a driving device 51 equipped with a driving wheel 511 and a stepper motor 516, and its rear portion has a jacking device 52 for jacking up the cargo trolley 1 so as to transport the cargo trolley 1 , equipped with a battery to provide power. In other embodiments, the AGV trolley 5 can also use t...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com