Laser scanning method for laser melting in selected area

A selective laser melting and laser scanning technology, which is applied in the direction of improving process efficiency and energy efficiency, can solve the problems of affecting scanning efficiency, discrete distribution, and small span of strip scanning partitions.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0031] Embodiments of the present invention will be described in detail below in conjunction with the accompanying drawings.

[0032] A laser scanning method for selective laser melting, the main steps of which include:

[0033] 1. Partition graphic division

[0034] According to the cross-sectional information of the workpiece, the workpiece area is divided into several partition graphics, the partition graphics include several grid-shaped regular triangles with a side length of 1mm~10mm and several irregular graphics on the boundary, and the gap between adjacent partition graphics The value of G is -1mm~1mm,

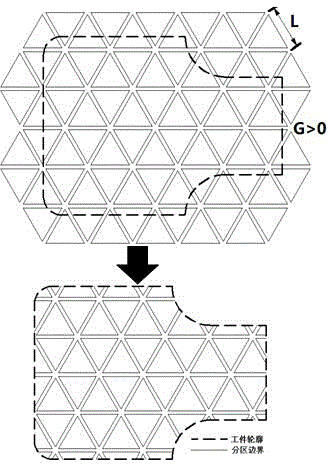

[0035] When G>0, there is a certain distance between adjacent partitions, such as figure 1 shown;

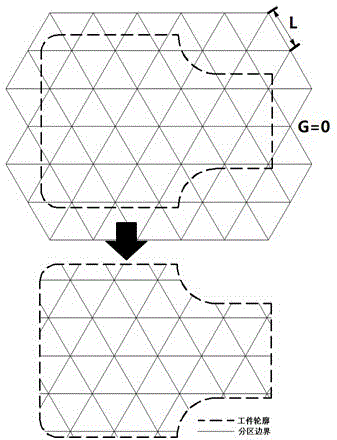

[0036] When G=0, adjacent partitions share one edge, such as figure 2 shown;

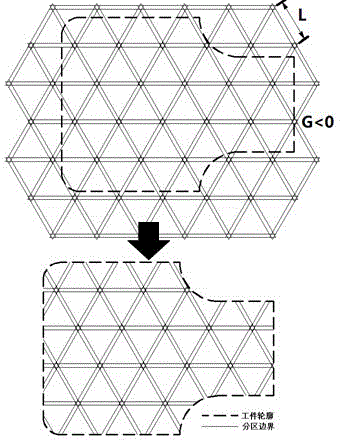

[0037] When G image 3 shown.

[0038] 2. Partition graphics scan

[0039] The irregular figure of the boundary is regarded as a partitioned regular triangle for scanning processing, an...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com