Method for improving laser scanning image light-curing quick-molding efficiency

A technology of laser scanning imaging and photocuring molding, applied in the field of imaging systems, can solve the problems of low efficiency and high cost, and achieve the effects of high spectroscopic efficiency, improved efficiency and improved scanning efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

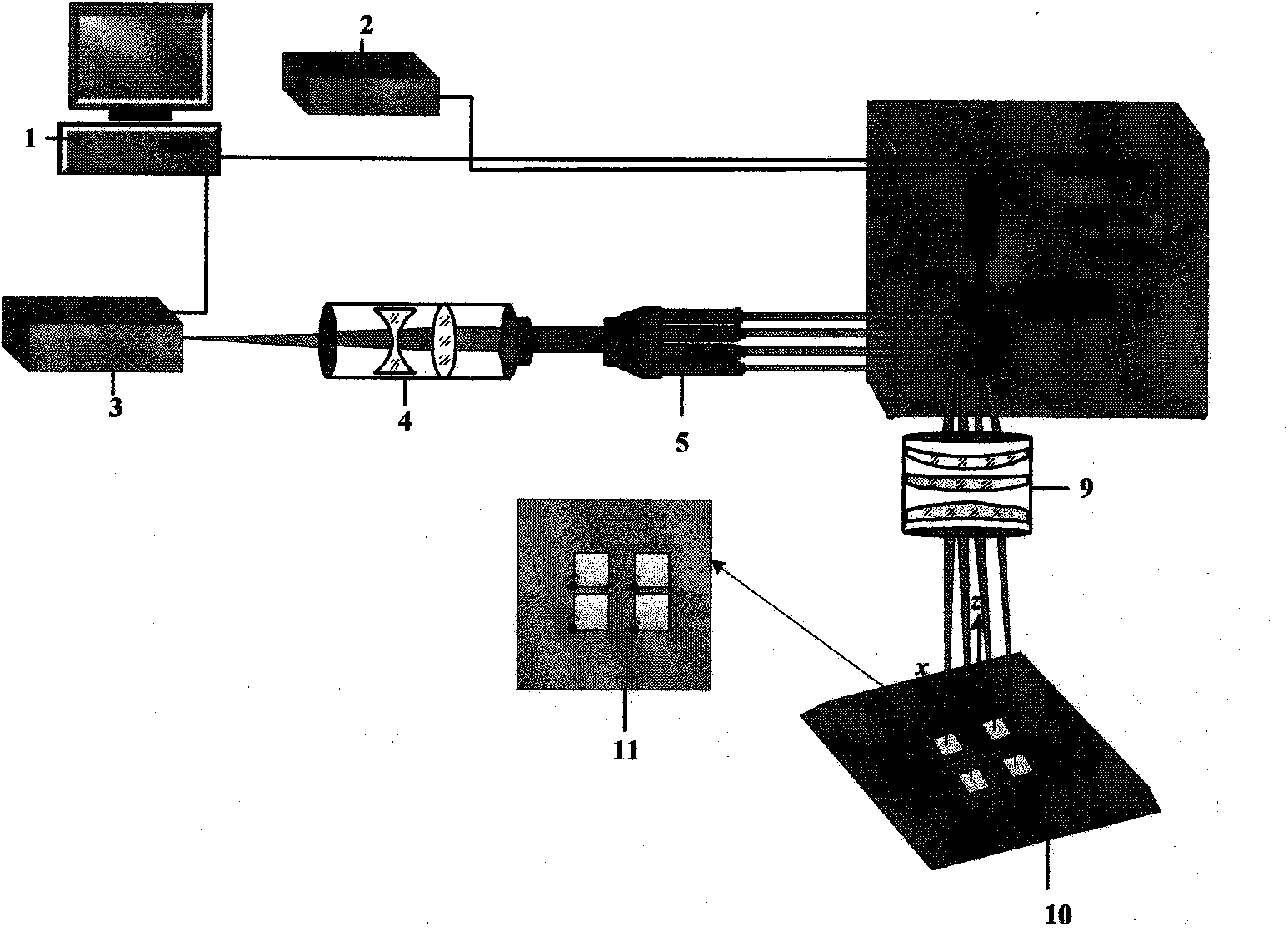

[0029] Embodiment 1: Collimated laser light source

[0030] Laser light source: When the laser scans the photosensitive resin, the photosensitizer in the photosensitive resin absorbs light energy of a certain wavelength, decomposes into free radicals or interacts with other molecules to generate free radicals, and then triggers a chain growth reaction, and the resin changes from liquid to solid state. Therefore, the choice of light source mainly depends on the absorption of photons of different frequencies by the photosensitizer. Most photosensitizers have a large light absorption coefficient in the ultraviolet region, so the photosensitive resin is easy to cure in the ultraviolet region, so the present invention preferably adopts a laser light source with a wavelength of 405nm. As the working medium in laser processing, the quality and stability of the laser beam will directly affect the operation of the scanning system. Therefore, it is required that the laser can operate n...

Embodiment 2

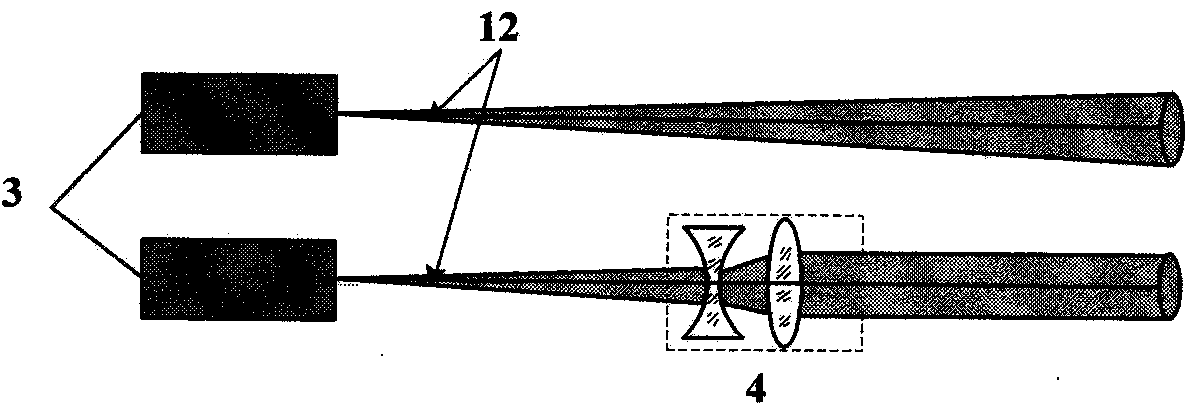

[0032] Embodiment 2: Optical fiber splitter

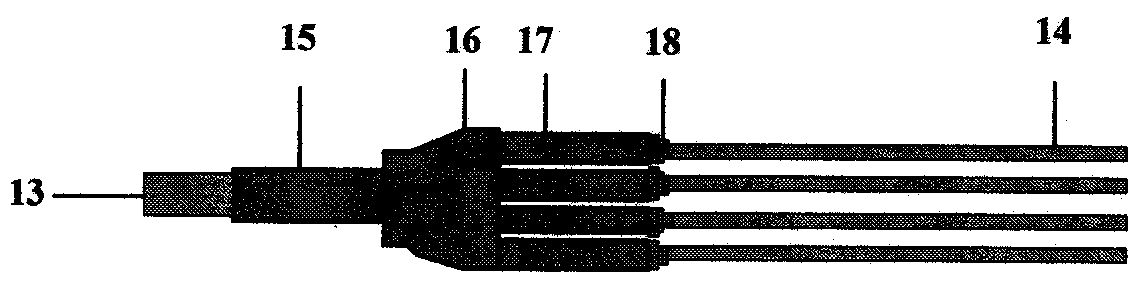

[0033] The optical fiber splitter can divide one optical signal into multiple outputs. The optical fiber splitter is preferably 405nm ultra-high transmittance ultraviolet energy transmission fiber, and the transmission efficiency per meter can reach 99%. The structure of the optical fiber splitter is as follows: image 3 shown.

[0034] The optical fiber splitter includes an input optical fiber and N output optical fibers, wherein the output optical fiber bundle includes a central output optical fiber arranged in the center and a plurality of peripheral output optical fibers arranged in the periphery. One branch of each optical fiber bundle contains N optical fibers before passing through the connection point, and is divided into N branches at the connection point, and each branch contains a single optical fiber.

[0035] Each output fiber is provided with N protective covers to prevent dust and other dirt, and the material of the...

Embodiment 3

[0037] Embodiment 3: scanning vibrating mirror: coated with high reflection film.

[0038] The galvanometer motor drives the galvanometer to scan the workpiece. The motor is required to have a large load inertia to ensure that the galvanometer can be loaded. The motor and the drive board receive the control signal from the computer to drive the galvanometer to rotate and complete the deflection of the laser beam. The scanning motor base is used to fix the scanning galvanometer motor to prevent the vibration during operation from affecting the processing, and the base should have a good heat dissipation effect.

[0039] The galvanometer scanning system consists of X and Y two-axis scanning galvanometers, focusing lenses and computer control systems. The scanning galvanometer uses X and Y two galvanometer scanning heads driven by high-speed reciprocating servo motors. Through the servos to the X and Y axes, the system sends command signals, and the X and Y servo motors can drive...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Wavelength | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com