Ultraviolet light curing anti fogging coating composite and preparing method thereof

A technology of anti-fog coating and composition, which is applied in the direction of polyester coating, polyether coating, epoxy resin coating, etc., can solve the problems of small actual production and complex process, and achieve high production efficiency, simple production process, and anti-fogging Excellent effect of fog performance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

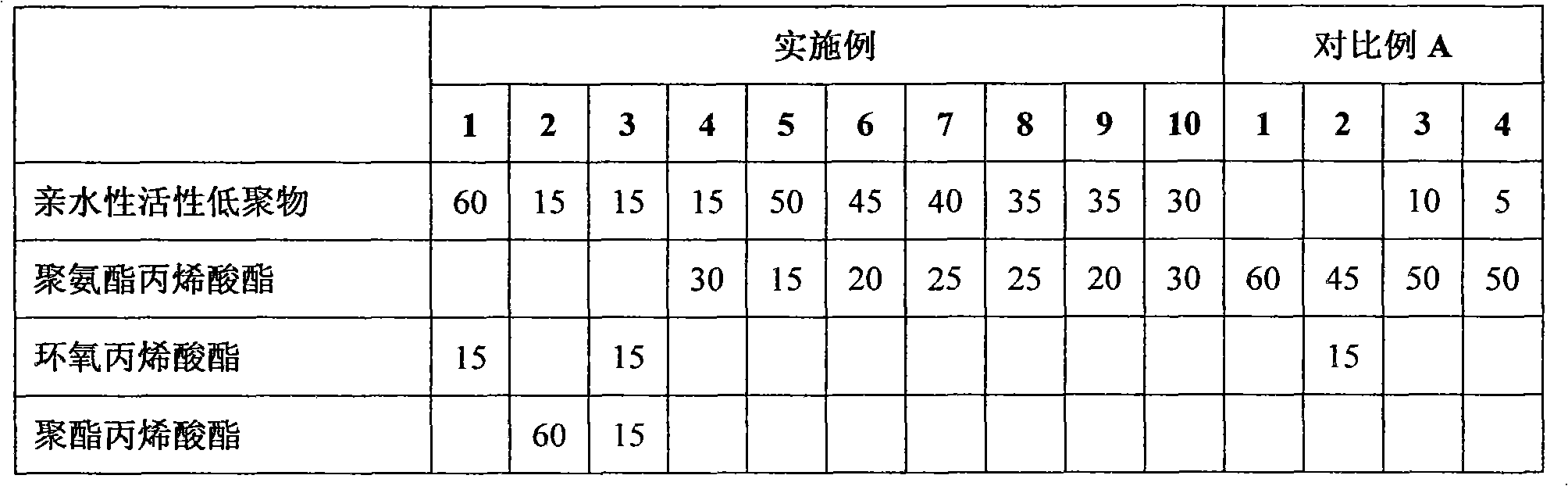

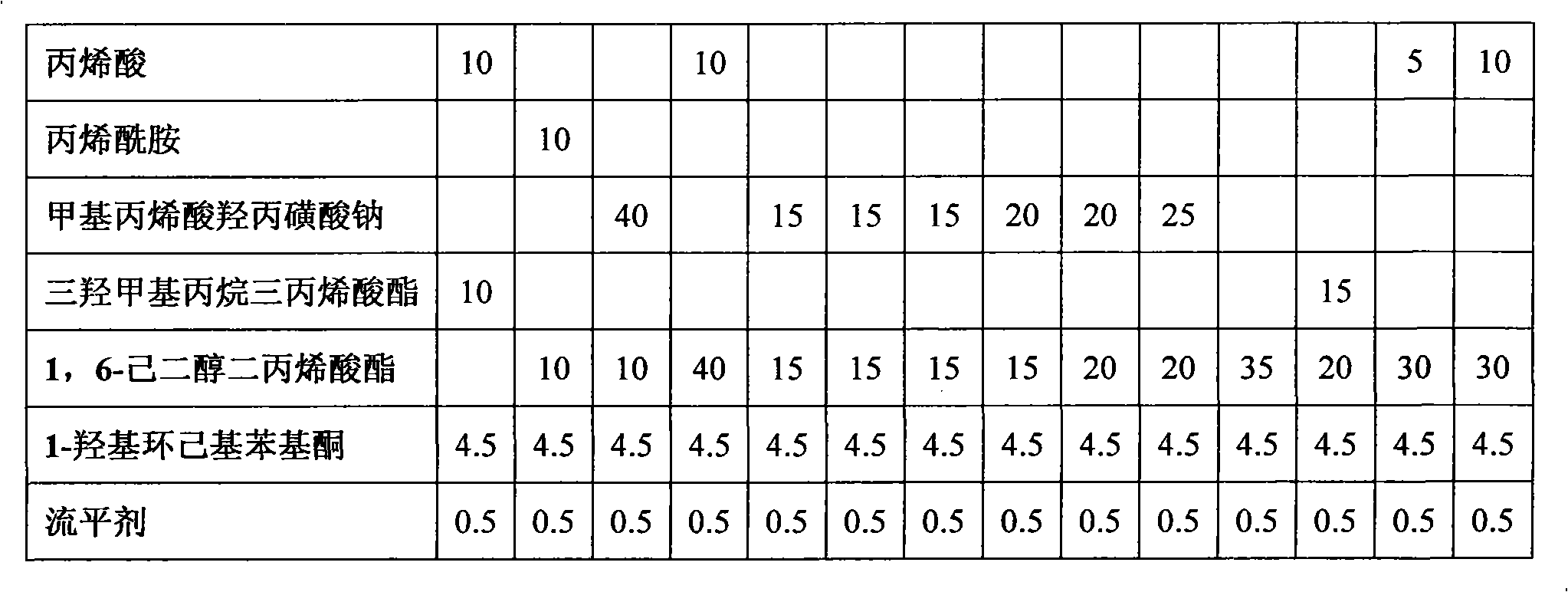

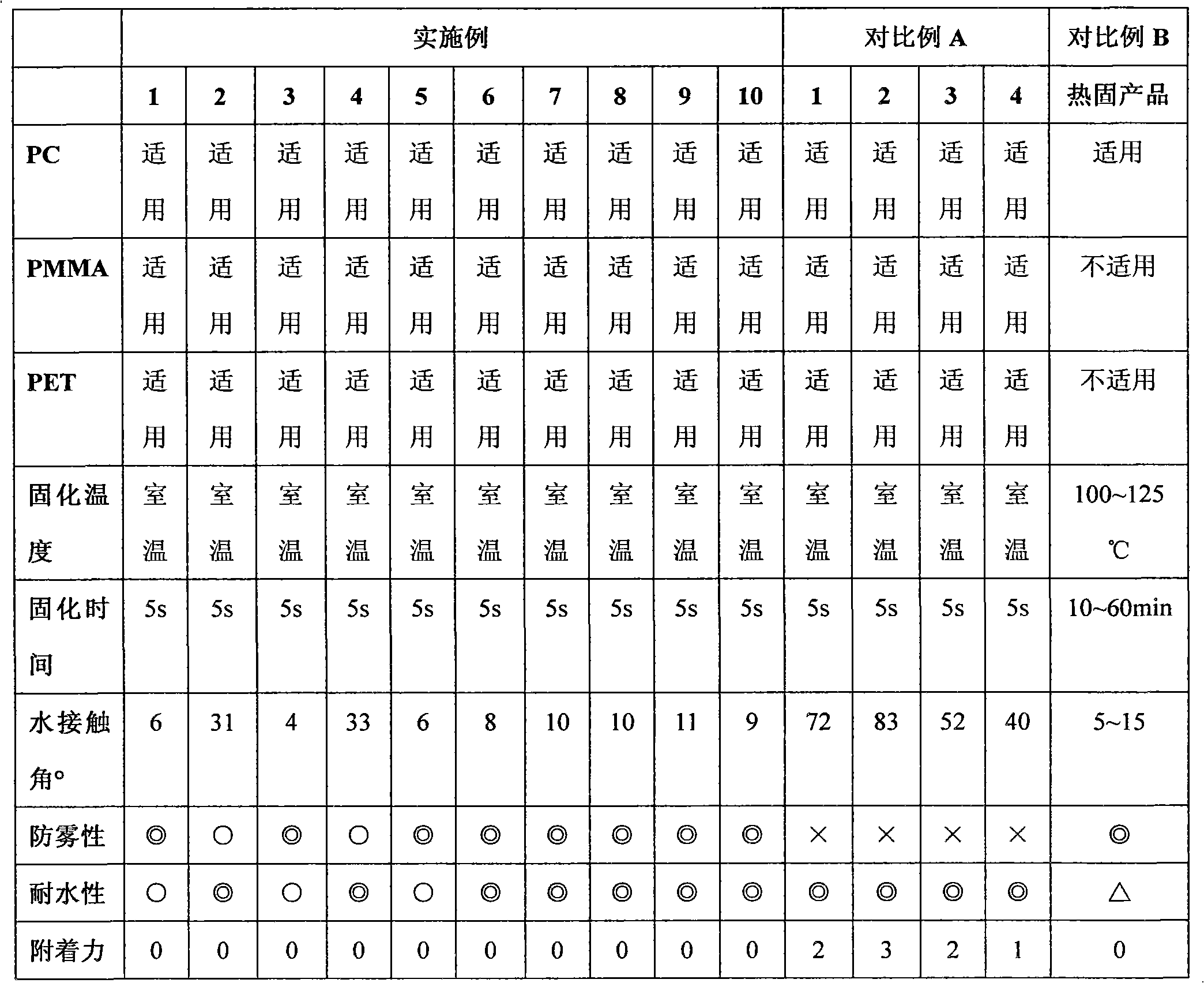

[0033] The present invention will be further described in detail below in conjunction with the examples, but not limited thereto.

[0034] The formula of embodiment and comparative example is as shown in table 1, and hydrophilic active oligomer is prepared by following method in the table:

[0035] With the PEG of different molecular weight (the molecular weight of PEG used among the embodiment 1-10 is respectively 3000,2000,400,600,1000,1500,1000,1000,1000 and 1000; The molecular weight of PEG among the comparative example A3-4 is respectively 1000 and 1500) react with toluene diisocyanate (TDI) or isophorone diisocyanate (IPDI) at 55-60° C. for 2 to 3 hours to obtain a polyurethane resin with terminal isocyanate groups, and then the polyurethane resin with terminal isocyanate groups is combined with The hydroxyethyl (meth)acrylate is reacted at 75-80° C. for 3-4 hours to obtain the hydrophilic active oligomer.

[0036] The preparation method of each embodiment and comparati...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com