Synchronous composite processing method of micro-hole electric sparks and different electrolytic areas and special tool of synchronous composite processing method

A composite machining and electric spark technology, which is applied in the field of micro-hole EDM-electrolysis different-area synchronous composite machining methods and special tools, can solve the problems of the influence of machining success rate, reduce electrode wear rate, reduce machining efficiency, etc., to avoid Excessive stray corrosion, maintenance of purity, effect of improving machining quality

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0033] The present invention will be further described below in conjunction with the accompanying drawings and specific embodiments.

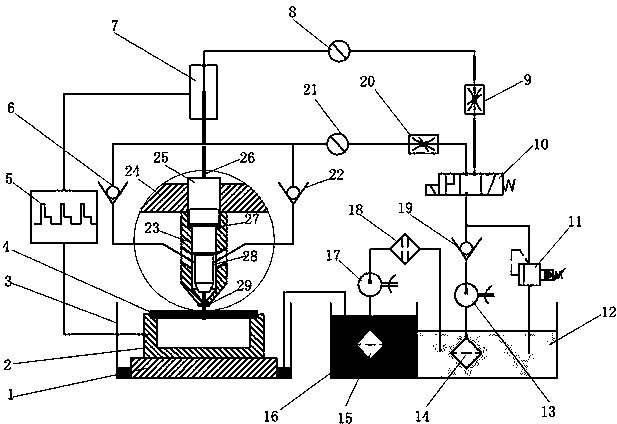

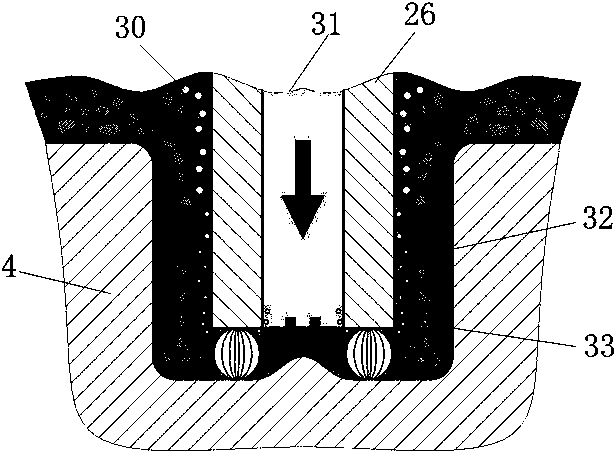

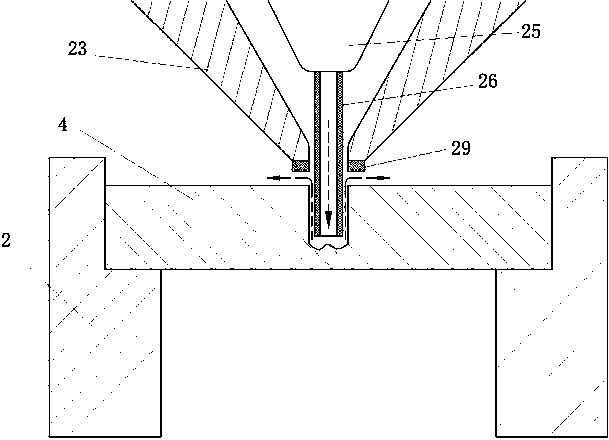

[0034] figure 1 It is a schematic diagram of a specific embodiment of the present invention. Workbench 1, fixture 2, work tank 3, workpiece 4, composite power supply 5, servo feed system 7, clamping device 24, and tube electrode 26 form an EDM-electrolysis composite processing platform, which consists of the first one-way valve 6, the second Two one-way valves 19, the third one-way valve 22, the first pressure regulating valve 9, the second pressure regulating valve 20, the first pressure gauge 8, the second pressure gauge 21, the first filter 14, the second filter 15 , Electromagnetic reversing valve 10, overflow valve 11, clean liquid tank 12, turbid liquid tank 16, multistage centrifugal pump 13, plunger type metering pump 17, fine filter 18, flow guide device 23, guide device 25, seal The pad 27, the diversion channel 28, the flushing liq...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com