Dispersion method for carbon nanotubes

A carbon nanotube, dispersing technology, applied in mixing methods, chemical instruments and methods, dissolution and other directions, can solve the problems of the influence of agglomeration effect, the inability to obtain effective dispersion, the ineffective solution of carbon nanotubes, etc., to achieve obvious dispersion effect. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment approach

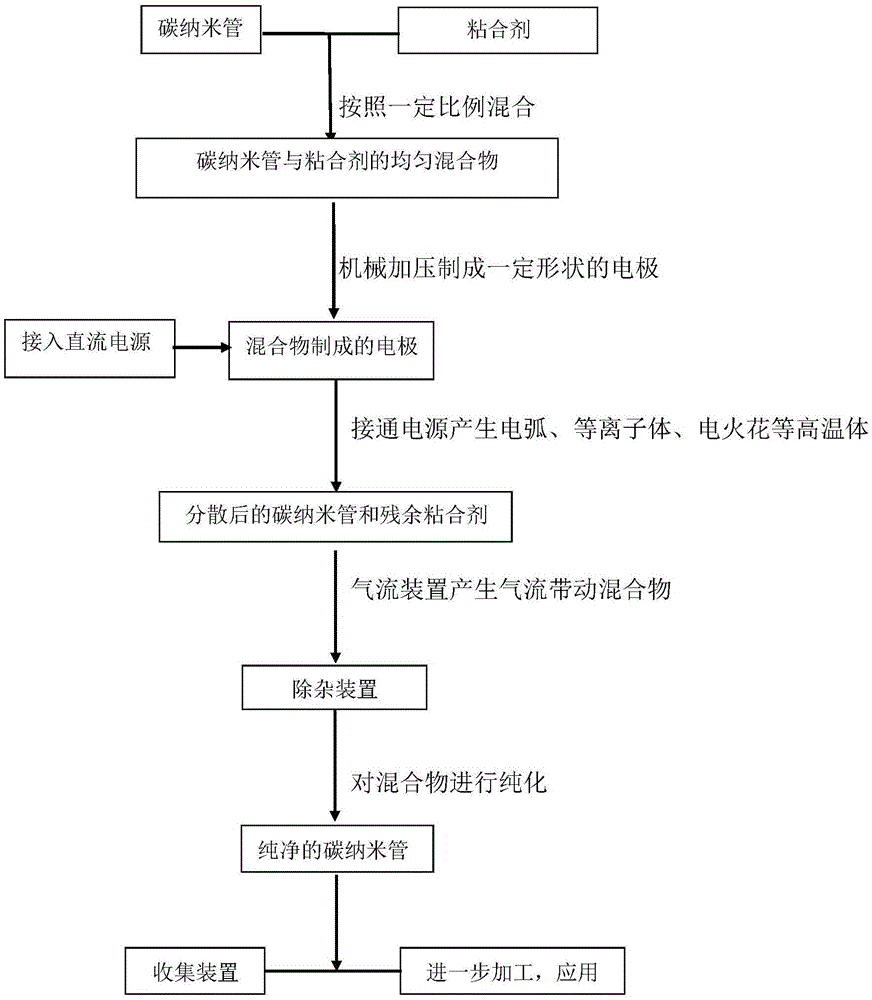

[0017] The invention provides a carbon nanotube dispersion method that has obvious dispersion effect and can realize large-scale preparation. The first is to configure a mixture of carbon nanotubes and binder for dispersion, and the formula is a certain proportion of carbon nanotubes and binder. The nanomaterials and the binder are mixed in a certain ratio, and then the mixture is pressed into a certain shape of solid and semi-solid electrodes with mechanical pressure. The carbon nanotube mixture electrode is connected to one pole of the DC power supply (to connect with It is advisable to connect the negative pole of the power supply), and then the other pole of the power supply made of graphite, metal and other materials is kept at a certain distance from the electrode composed of carbon nanotube mixture. Turn on the power and the circuit to generate a certain intensity of electric heating sources such as arc, plasma, and electric spark between the two electrodes. The high tem...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com