Integrated device of ultrasound auxiliary electric spark deposition and repair and ultrasound polish and method thereof

An electric spark deposition, ultrasonic-assisted technology, applied in the direction of arc welding equipment, manufacturing tools, welding equipment, etc., can solve the problems of inability to obtain a large repair thickness deposition layer, limit promotion, etc., achieve low repair cost, broaden the repair field, and operate simple effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

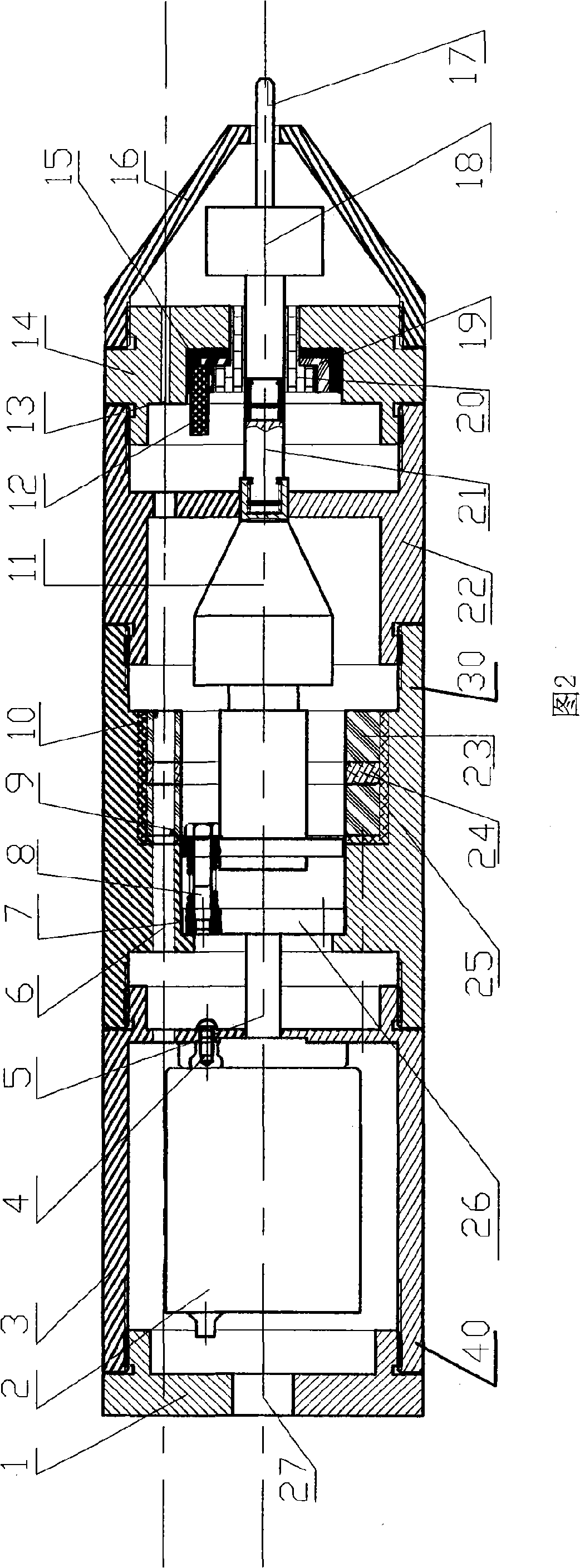

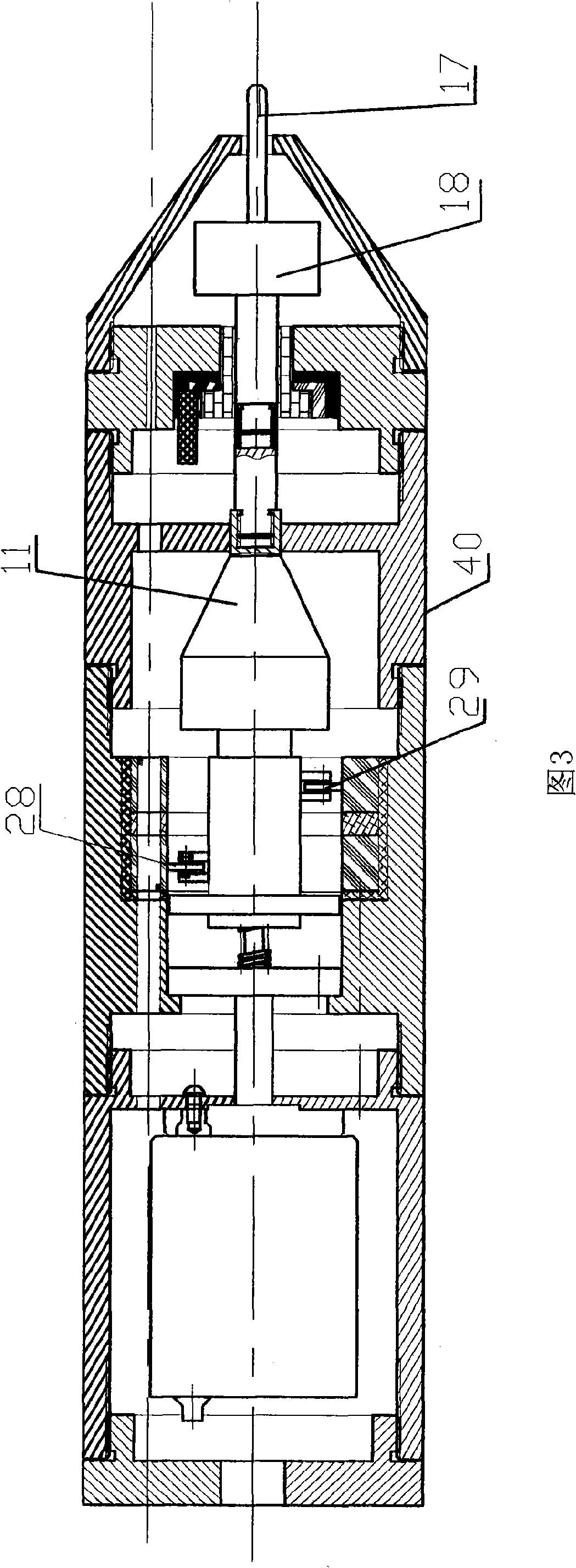

[0034] The structural representation of the present invention is as shown in Figure 1, 2, 3, comprises gas supply device, power supply and control box 34, wiring 35, electrode device 37, work chuck 39, and wherein gas supply device comprises argon cylinder 31, Pressure decompression gauge 32, ventilation hose 33, electrode device 37 includes shell 40, motor main shaft 5, first transducer terminal rod 9, second transducer terminal rod 10, transducer 11, electrode terminal rod 12 , protective gas connection 13, tool material 17, clamping head 18, conductive gasket 19, slider 20, insulating ceramic shaft 21, second transducer conductive gasket 23, first transducer conductive gasket 25, insulation Gasket 24, insulating gasket 26, the first transducer is connected to the electric rolling disk 28, and the second transducer is connected to the electric rolling disk 29, wherein the motor spindle 5 is connected to the transducer 11 through the flange 27, and the energy conversion The f...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com