Device and method for detecting discharge state in electric spark linear cutting work gap

A discharge state and cutting processing technology, which is applied in the field of detection devices for gap discharge state in wire electric discharge cutting, can solve problems such as inability to process, increase feed speed, and high average voltage, and achieve good real-time performance, wide application range, and convenient operation Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0041] The wire electric discharge machining of embodiment 1 metal material

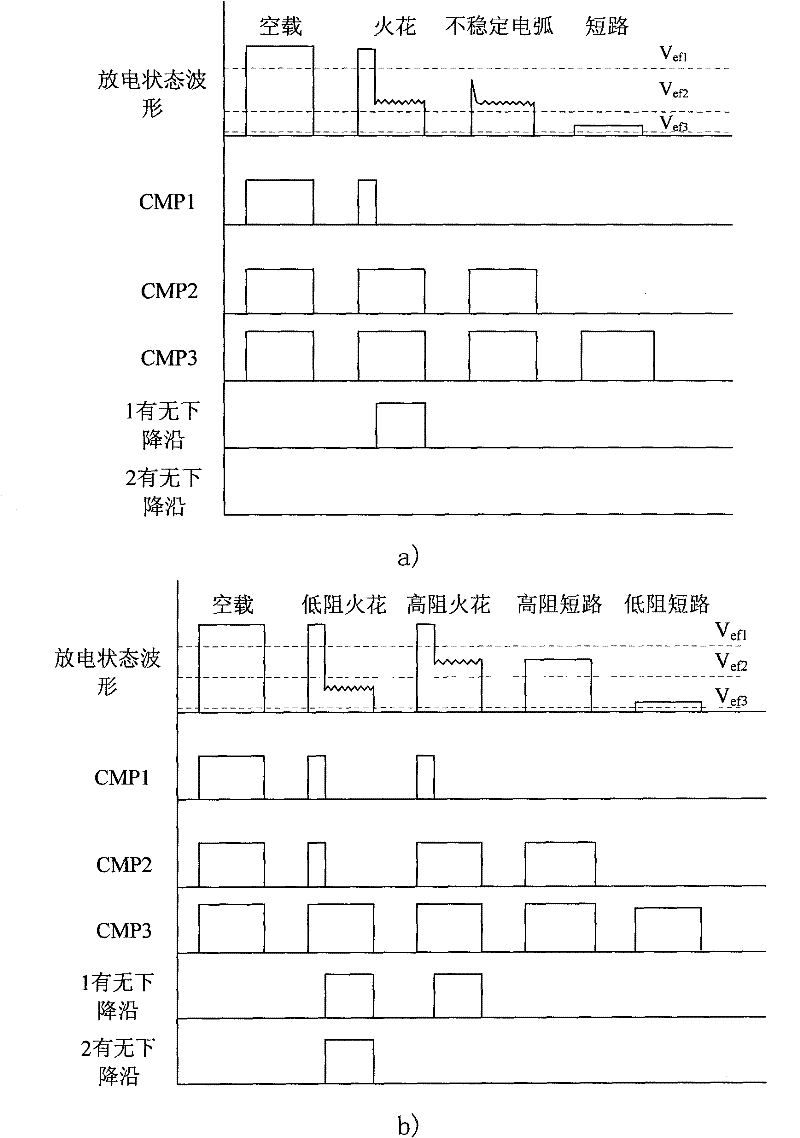

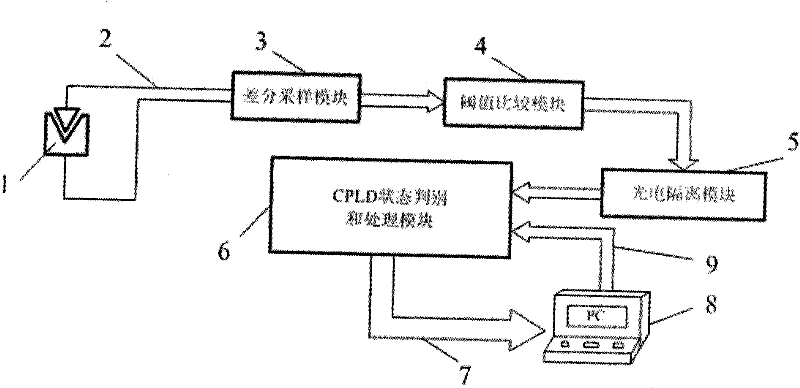

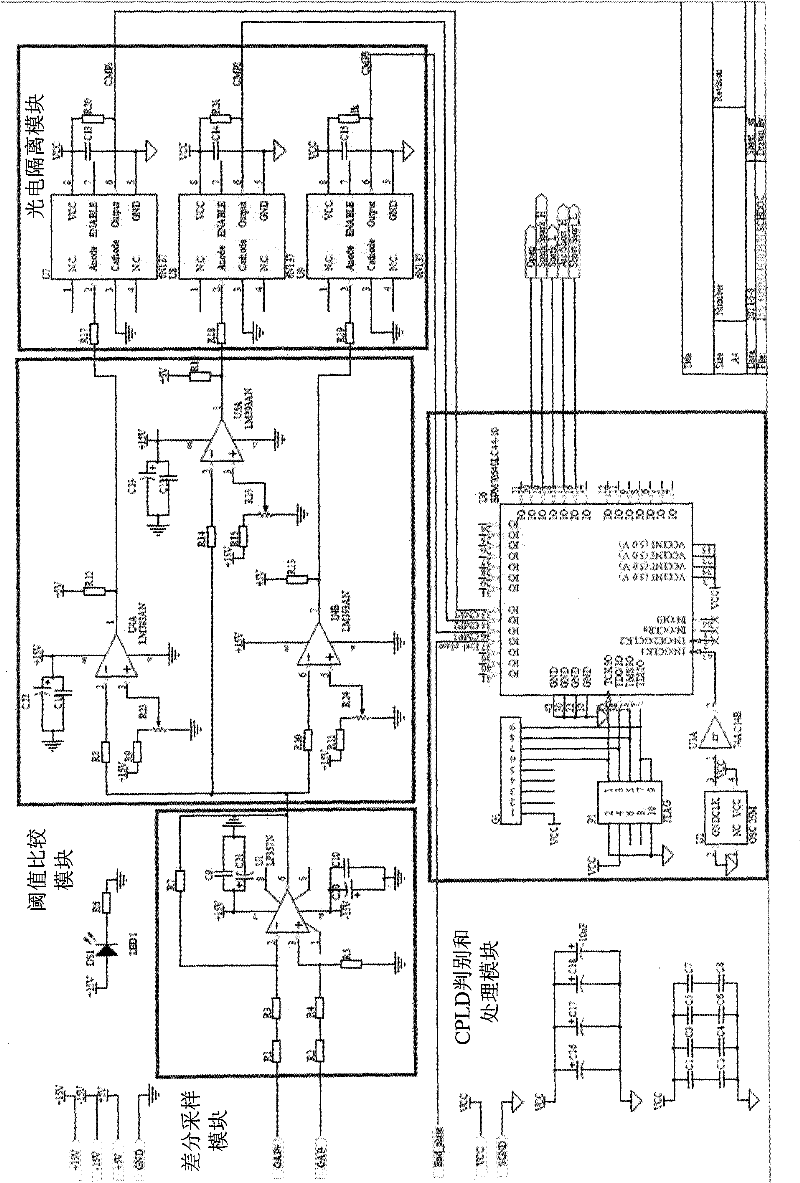

[0042] Hardware circuit and CPLD internal circuit such as Figure 2-5 mentioned, only need to adjust V ef1 , V ef2 , V ef3 Three thresholds are enough. The corresponding threshold setting value is relative to the no-load voltage, and the threshold setting of the three comparators of the threshold comparison module corresponds to the threshold V ef1 , V ef2 , V ef3 , but its value is equal to V ef1 , V ef2 , V ef3 Multiplied by the sampling scale of the differential sampling block. Threshold V ef3 It is set to 3~5V. Its function is to distinguish the pulse width and pulse interval of each pulse. The control detection program only judges the discharge state during the pulse width, and does not judge the state during the pulse interval to prevent misjudgment. Threshold V ef2 Set to be slightly less than the metal pulse discharge sustain voltage value, the threshold V ef1 Set slightly below ...

Embodiment 2

[0045] Embodiment 2 Wire-cut electric discharge machining of insulating ceramic material

[0046] Hardware circuit and CPLD internal circuit such as Figure 2-5 mentioned, only need to adjust the threshold V ef2 That's it. Threshold V ef2 It is set to be slightly larger than the metal pulse discharge sustaining voltage value, so in the WEDM of insulating ceramics, V ef3 set to 3V, V ef2 Set to 40V. V ef1 Set to 70V.

[0047] The gap voltage enters the threshold comparison module through the differential sampling module, and compares it with the set threshold. After photoelectric isolation, the waveforms of the CMP1, CMP2, and CMP3 signals, as well as the outputs of the CPLD internal breakdown signal detection modules Inst1 and Inst33, such as figure 1 b) as shown.

[0048] During the high level period of CMP3, that is, the pulse width period, different gap discharge states have different CMP1 and CMP2 signals. During the pulse width, if the output of CMP1 and CMP2 has...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com