Method for electrically controlling hydraulic differential of centrifuge

An electrical control and centrifuge technology, applied in centrifuges and other directions, can solve the problems of inability to produce high-precision mechanical automatic control valves, high prices, and inability to be widely used, and achieve simple structure, reduce production costs, and speed up discharge. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0023] The present invention will be further described below in conjunction with accompanying drawing:

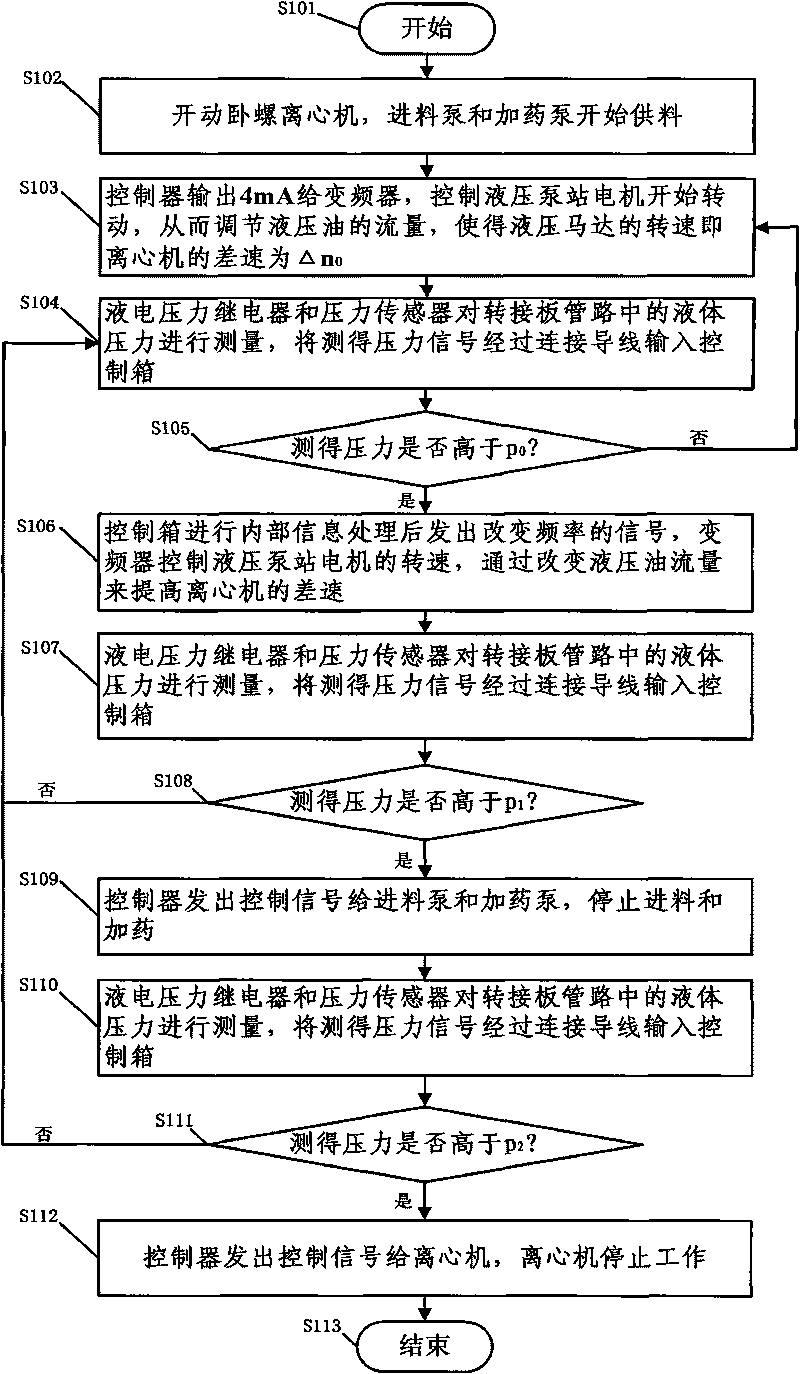

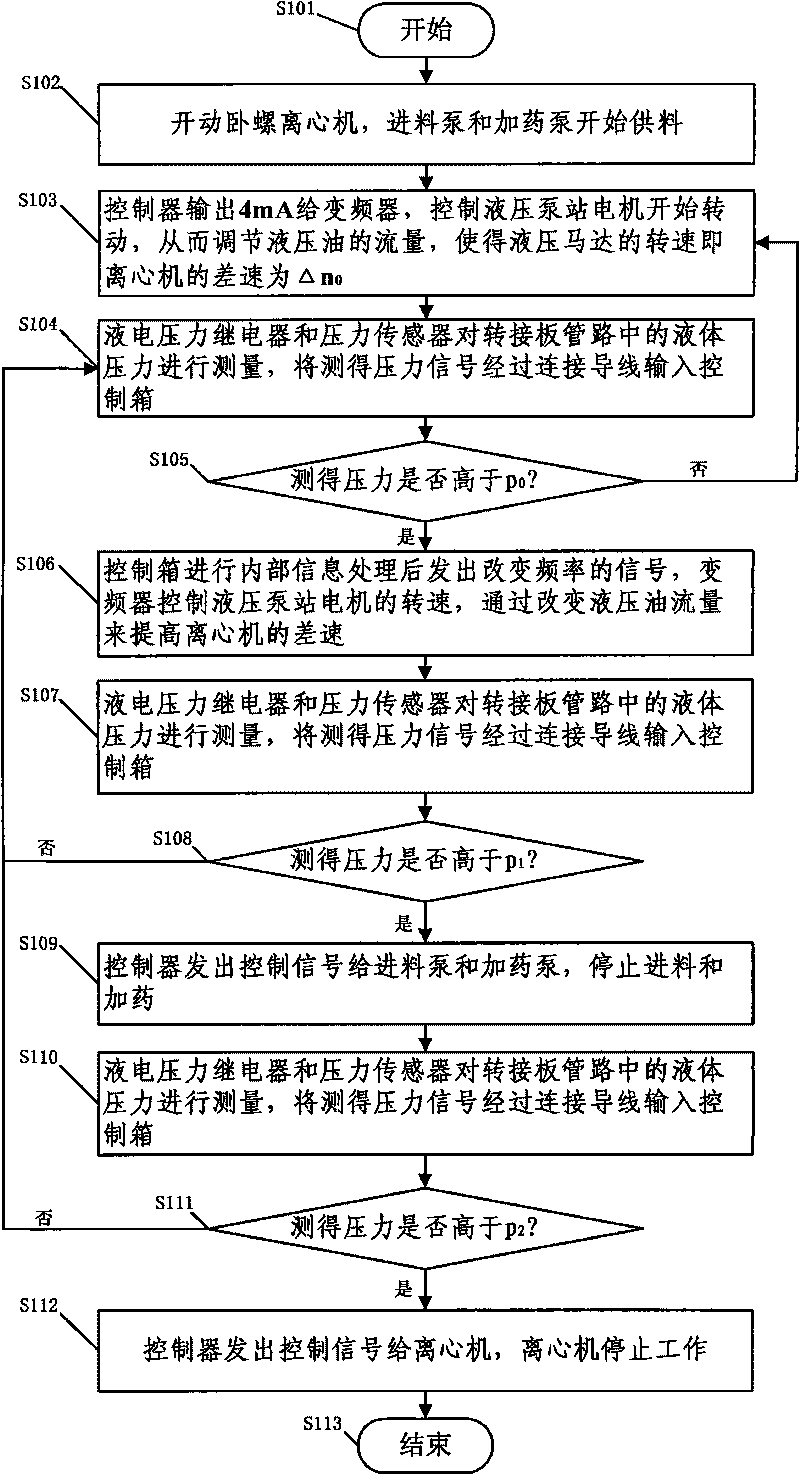

[0024] figure 1 It is a flow chart of the electric control method for the hydraulic differential speed of the centrifuge of the present invention. The process starts at step 101 . Then in step 102, the decanter centrifuge is started, and the feed pump and the dosing pump start to supply materials.

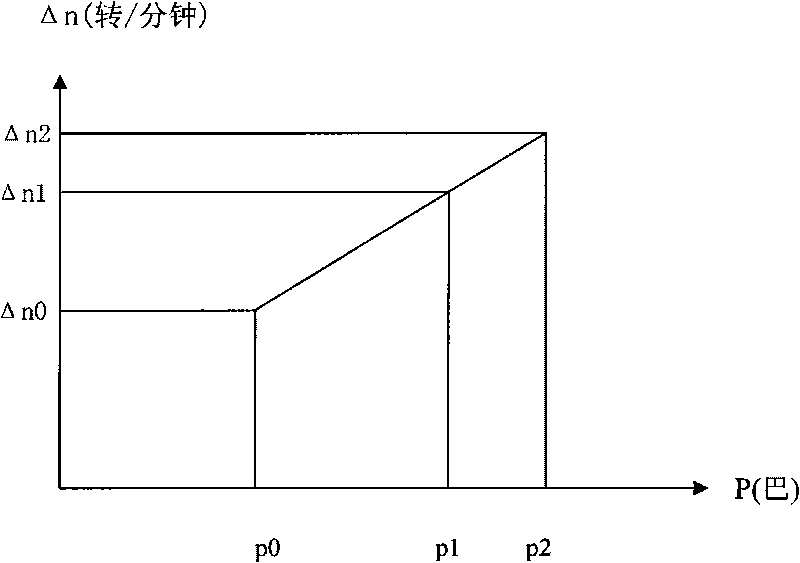

[0025] In step 103, the controller outputs 4mA to the frequency converter to control the motor of the hydraulic pump station to start rotating, thereby adjusting the flow of hydraulic oil so that the speed of the hydraulic motor, that is, the differential speed of the centrifuge, is Δn 0 .

[0026] In step 104, the liquid-electric pressure relay and the pressure sensor measure the liquid pressure in the pipeline of the adapter plate, and input the measured pressure signal into the control box through the connecting wire.

[0027] In step 105, the above-mentioned measured pre...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com